Aluminum alloy section quenching device

An aluminum alloy profile and quenching device technology, which is applied in the field of aluminum alloy processing, can solve the problems of uneven cooling of square pipes, uneven cooling range, and reduced performance of square workpieces, so as to prevent stress concentration, uniform cooling, and reduce friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

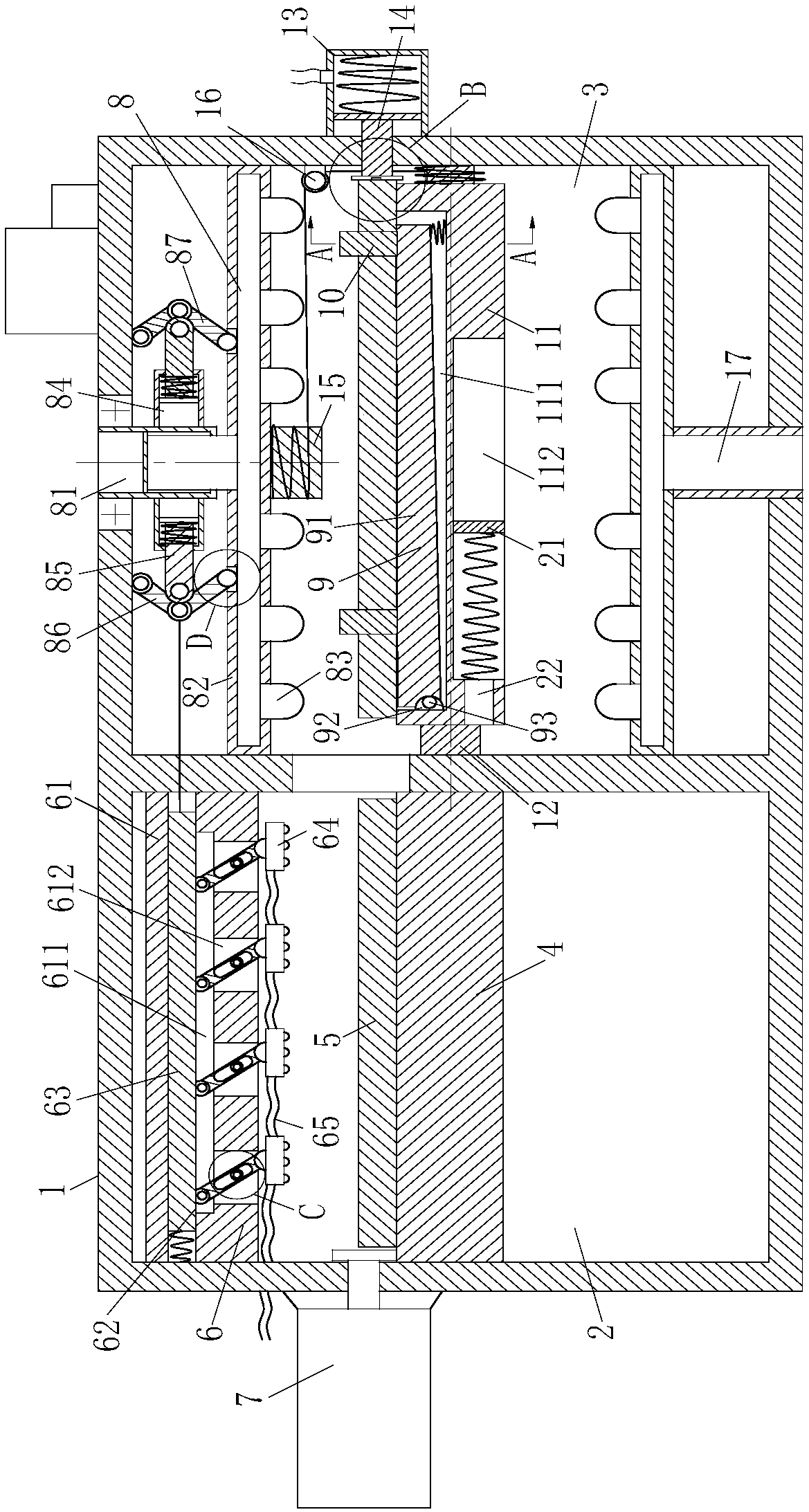

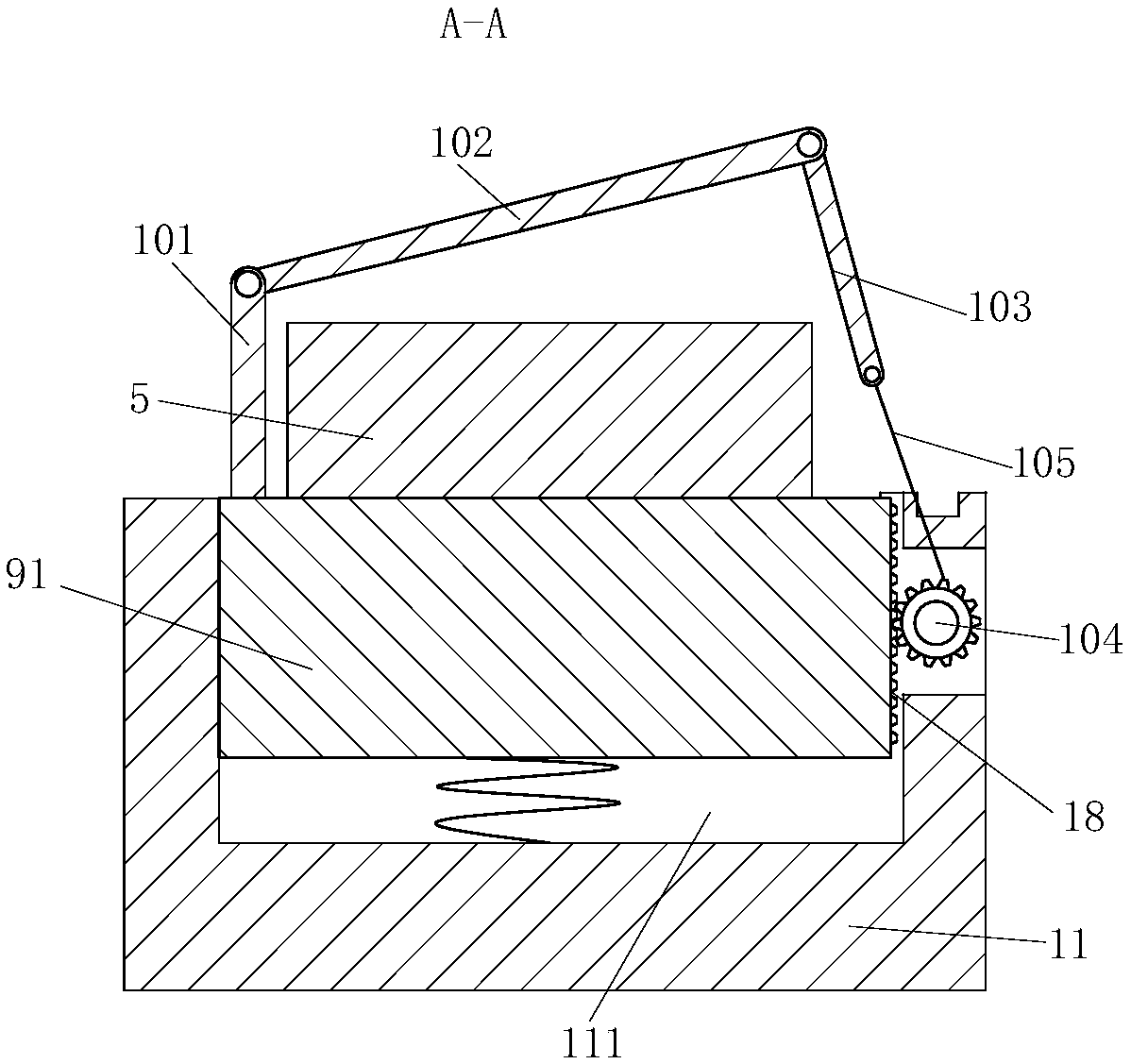

[0032] As an embodiment of the present invention, the second support plate 11 is provided with a swing groove 111, and the swing unit 9 is located in the swing groove 111; the swing unit 9 includes a rotating plate 91, a hinge seat 92, and a hinge shaft 93 , compression spring; the inner end of the swing groove 111 is provided with a hinge seat 92; the rotating plate 91 is hinged with the hinge seat 92 through the hinge shaft 93, and the bottom end surface of the rotating plate 91 is provided with a compression spring, and the rotating plate 91 is inclined Set in the swing groove 111; the two ends of the rotating plate 91 are provided with locking units 10; the swing unit 9 is provided, when the workbench 5 moves on the rotating plate 91, the inclined rotating plate 91 will The gravity of the table 5 moves downward, and the compression spring compresses downward, so that the locking unit 10 fixes the square workpiece.

[0033] As an embodiment of the present invention, the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com