Alpha-glucosidase mutant and application thereof

A glucosidase and mutant technology, applied in the field of genetic engineering, can solve the problems of unfavorable environmental protection, complicated operation, severe reaction conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Cloning of α-glucosidase gene derived from Aspergillus nidulans and construction of expression vector

[0046] The synthetic target gene AgdB(-) (nucleotide sequence shown in SEQ ID NO.2) was connected to the cloning vector pMD19T, called pMD19T-AgdB(-), transformed into E.coli JM109 for further cloning, and the target gene was digested and recovered. The gene was connected with the expression vector pPIC9K overnight at 16°C, transformed into E.coli JM109, coated with LB plate containing kana (30μg / mL) resistance, cultured at 37°C for 10-12h, picking transformants, extracting recombinant plasmids and Double digestion verification, and then determine the DNA sequence of the verified recombinant plasmid, the positive clone is AgdB(-)-pPIC9K.

Embodiment 2

[0047] Embodiment 2: Transformation of recombinant plasmid AdgB(-)-pPIC9K

[0048] The plasmid AdgB(-)-pPIC9K was electrotransferred into the competent Pichia pastoris KM71 prepared in advance to obtain the genetically engineered bacteria Pichia pastoris KM71 / AgdB(-)-pPIC9K, which was cultured on an MD plate at 30°C for 3-4 days. After the transformants were obtained, they were picked on G418 / YPD plates with different concentrations to screen positive clones, and cultured at 30°C for 24h. Pick a single colony into 10mL of YPD liquid medium, culture at 30°C for 24h, save the glycerol tube, and store it in a -80°C refrigerator. After the verification is correct, shake flask fermentation is carried out to produce enzyme.

Embodiment 3

[0049] Embodiment 3: Shake flask fermentation produces enzyme

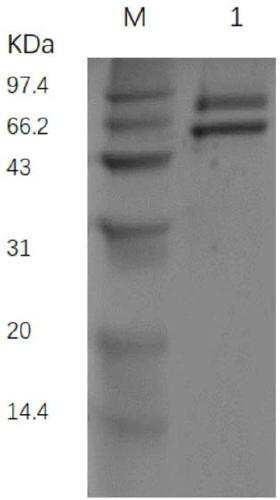

[0050] The recombinant Pichia strain obtained in Example 2 was inoculated in YPD medium, and after culturing at 30°C for 24h, it was transferred to 50mL BMGY medium with 5% inoculum size and cultivated in a constant temperature shaker at 30°C for 24h, and then Centrifuge at 5000rpm for 5min, discard the supernatant, collect the bacteria, hang the bacteria with 25mL BMMY medium, add 1.5% methanol to induce enzyme production in the bacteria, cultivate in a constant temperature shaker at 30°C for 120h, add 1.5% methanol every 24h After the induced fermentation, centrifuge at 5000rpm for 20min, and the supernatant is the recombinant α-glucosidase. The measured activity of α-glucosidase in the supernatant can reach 16U / mL, which is 1.58 times higher than that of the wild enzyme. Shake flask fermentation to OD 600 The protein content of 40 is 0.4g / L. The results of protein electrophoresis showed that there was a band...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conversion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com