Anti-electromagnetic radiation isolating board for electric working room

An anti-electromagnetic radiation, studio technology, applied in the direction of film/flake adhesives, adhesives, etc., can solve the problems of easy generation of static electricity, inconvenient use, tearing of metal mesh, etc., to achieve heavy weight and easy installation. , easy to cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

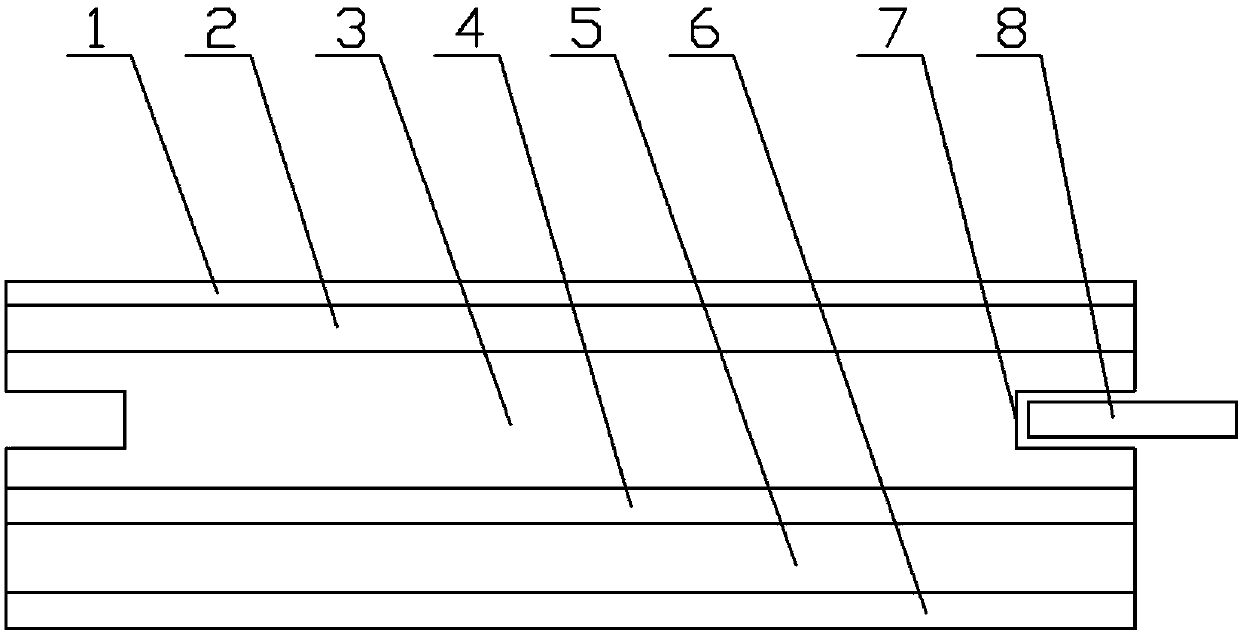

[0024] according to figure 1 , figure 2 with image 3 , the electric working room anti-electromagnetic radiation isolation board, which includes a base plate 3; the front and rear of the base plate 3 are respectively provided with a first radiation-proof layer 4 and a second radiation-proof layer 2 with the same structure; The front of the radiation layer is provided with an insulating layer 5; the front of the insulating layer 5 is provided with an antistatic coating 6; The adhesive 9 consists of: the copper fiber wires 10 and the silver fiber wires 11 are uniformly interlaced.

[0025] The present invention replaces the metal mesh in the radiation protection layer of the prior art with interlaced copper fiber wires 10 and silver fiber wires 11, and the copper fiber wires and silver fiber wires can be easily cut off during the cutting process, or the whole copper wire The fiber wire or silver fiber wire is pulled out, the radiation protection effect will not be weakened, ...

Embodiment 2

[0034] according to Figure 4 , the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the two isolation plates are connected by a connecting piece 12, the cross section of the connecting piece 12 is in an inverted “T” shape, and the connecting piece 12 It is glued to the side and front of the isolation board, and the connecting piece 12 is made of insulating material.

[0035] When installing, you can first paste the two isolation boards on the wall through the adhesive layer 1, then apply glue on both sides of the connector 12, and then squeeze and press from between the two isolation boards. The connector 12 can prevent isolation The edge of the board, falling off, etc.

[0036] The invention has reasonable structure and convenient installation, replaces the metal mesh in the prior art radiation protection layer with metal fiber wires, is convenient for cutting, and effectively solves the technical problem of inconvenient use...

Embodiment 3

[0038] A wood-plastic board, which is prepared according to the following process:

[0039] The raw materials were weighed according to parts by weight for later use: 1 part of magnesium oxide, 1 part of barium sulfate, 1 part of attapulgite, 2 parts of bentonite, 2 parts of graphite, 5 parts of polypropylene, 5 parts of polyvinyl chloride, and 15 parts of wood flour.

[0040] Add each raw material to the mixer in turn, stir at 500rpm for 3 minutes, then enter the twin-screw extruder to extrude into a molten state, then inject into the mold for shaping treatment, eject the mold, and then enter the incubator to maintain the temperature at 150°C , the time is 5 minutes; take it out, put it into a large-tonnage cold press, pressurize the pressure of 500 tons, pressurize for 10 minutes, cool and shape the semi-finished product; then cut the semi-finished product vertically and horizontally under the traction of the tractor, and then enter the large-scale Sanding machine, sanding o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com