Water-based high-clarity high-scratch-resistance five-splitting main finish paint as well as preparation method thereof and double-component clear surface paint

A two-component, clear topcoat technology, applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., to achieve the effects of good hardness and scratch resistance, compact paint film, and good wrapping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

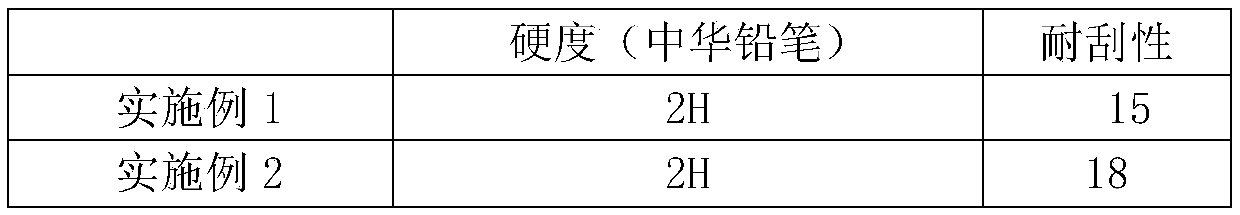

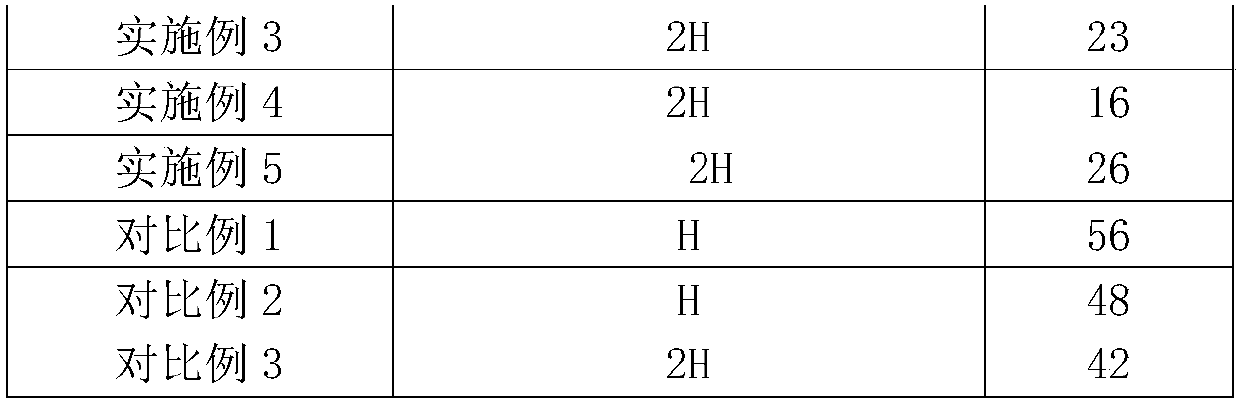

Examples

Embodiment 1

[0038] The preparation method of the main paint: Weigh the components according to the weight ratio, add the hydroxyacrylic acid emulsion into the volume of the stainless steel, and add the anti-mold and fungicide, the PH value regulator, the medium viscosity thickener, and the emulsifier in turn under the dispersion state of 500R / M Wet dispersant, antifoaming agent, and nano-silica sol are dispersed for 10 minutes to a uniform state; then add glass powder / aluminum oxide and water-based wax slurry in a stirring state, and disperse at a speed of 1000R / M for 15 minutes to a fineness≤25um ; Then add the mixture of coalescent and deionized water, surface control agent, substrate wetting agent in turn

[0039] High-viscosity thickener, disperse at 700R / M for 10 minutes until uniform, and filter through a 300-mesh filter cloth to obtain a high-definition, high-scratch, anti-scratch, five-point clear topcoat; main paint: curing agent: water = 100:30:15 by weight After mixing evenly, ...

Embodiment 2

[0061] The composition of the main paint formula: proportioning by weight

[0062] 1: 72 parts of hydroxyl acrylic emulsion, the hydroxyl value is 3

[0063] 2: 0.3 parts of anti-mildew fungicide

[0064] 3: 0.3 parts of pH regulator

[0065] 4: 0.3 parts of medium viscosity thickener

[0066] 5: Wetting and dispersing agent 0.3 parts

[0067] 6: 0.3 parts of foam suppressor

[0068] 7: 8 parts of nano silica sol

[0069] 8: 7 parts of glass powder / aluminum oxide (3:1)

[0070] 9: 2 parts water-based wax paste

[0071] 10: 5 parts of film-forming aid

[0072] 11: 3.9 parts of deionized water

[0073] 12: 0.2 parts of surface control agent

[0074] 13: Substrate wetting agent 0.2 parts

[0075] 14: 0.2 parts of high viscosity thickener

[0076] Curing agent formula: aliphatic polyisocyanate 80 (NCO content 21%)

[0077] Propylene glycol methyl ether acetate 20

[0078] The weight ratio of the main paint and the curing agent is calculated according to the NCO conten...

Embodiment 3

[0080] The composition of the main paint formula: proportioning by weight

[0081] 1: 70 parts of hydroxy acrylic emulsion, the hydroxyl value is 3

[0082] 2: 0.2 parts of anti-mildew fungicide

[0083] 3: 0.5 parts of pH regulator

[0084] 4: 0.4 parts of medium viscosity thickener

[0085] 5: Wetting and dispersing agent 0.5 parts

[0086] 6: 0.3 parts of foam suppressor

[0087] 7: 10 parts of nano silica sol

[0088] 8: 8 parts of glass powder / aluminum oxide (3:1)

[0089] 9: 1 part water-based wax paste

[0090] 10: 3 parts of film-forming aid

[0091] 11: 5.4 parts of deionized water

[0092] 12: 0.3 parts of surface control agent

[0093] 13: Substrate wetting agent 0.1 part

[0094] 14: 0.3 parts of high viscosity thickener

[0095] Curing agent formula: according to the following proportions by weight

[0096] Aliphatic polyisocyanate 80 (NCO content 21%)

[0097] Propylene glycol methyl ether acetate 20

[0098] The weight ratio of the main paint and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com