Method for preparing highly grafted silanization modified clay/rubber nanocomposite material

A technology of rubber nano-composite materials, applied in the field of polymer materials, can solve the problems of general modification effect, affecting grafting effect, etc., and achieve the effect of overcoming aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Add 800 g of natural sodium-based montmorillonite to 10 L of deionized water, stir at a speed of 800 r / min for 8 hours, let stand for 24 hours, take the upper layer to clear the night, and obtain a montmorillonite suspension with a solid content of 5%, dilute with water to montmorillonite suspension A with a solid content of 3%. 180 g of absolute ethanol was dissolved in 10 g of deionized water, and 0.20 g of concentrated hydrochloric acid was added to make the hydrogen ion concentration in the solution 0.008 mol / L. Control the temperature of the system at 20°C. After ultrasonication for 5 minutes, add 10.0 g of γ-methacryloxypropyltrimethoxysilane (KH570) dropwise into the solvent, stir for 10 minutes, let stand for 5 minutes, and add to 333 g of Mongolian In the desoil suspension A, the temperature was raised to 85° C., and the reaction was stirred for 5 hours to obtain the suspension B.

[0062] Table 2 shows the grafting situation of the clay modified with acidifyi...

Embodiment 2

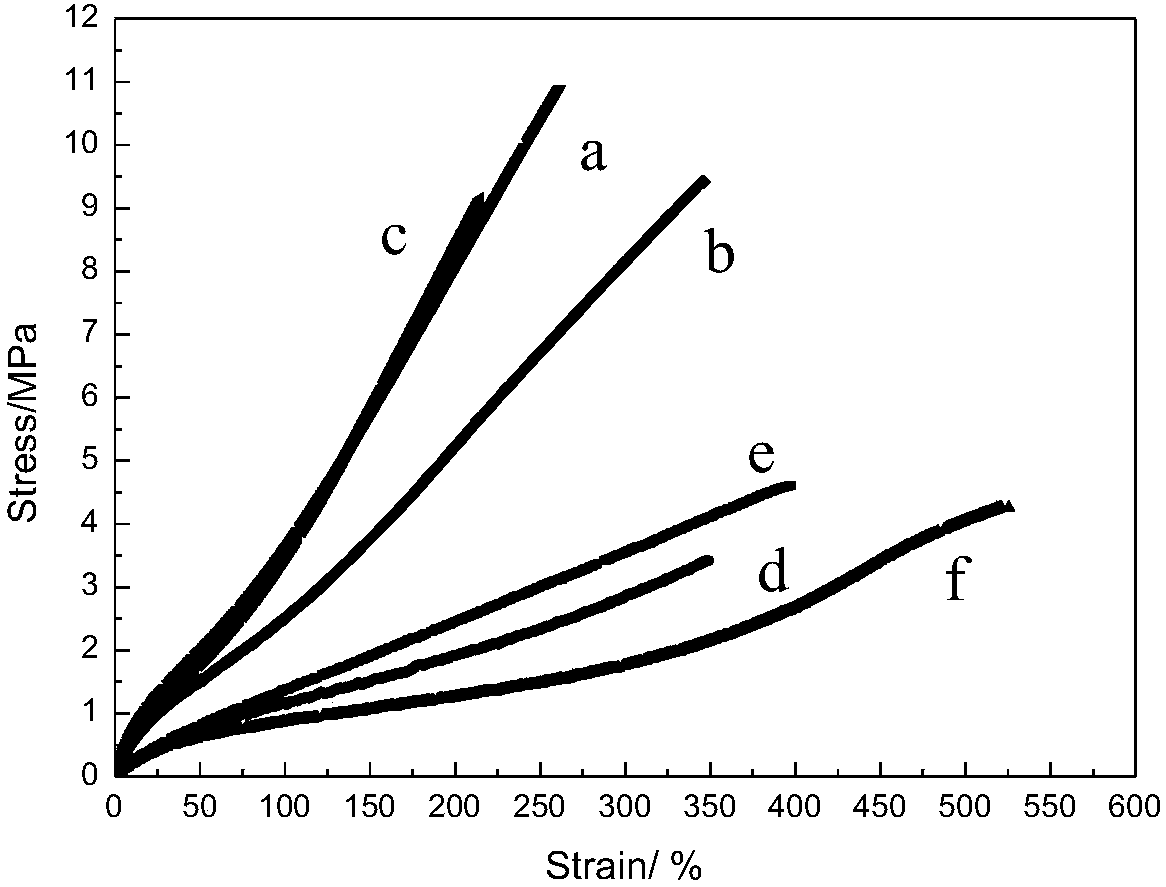

[0066] The difference from Example 1 is that the mass of hydrochloric acid used to acidify γ-methacryloxypropyltrimethoxysilane in this example is 0.08 g, so that the concentration of hydrogen ions in the solution is 0.003 mol / L. Other vulcanization aids and implementation process are identical with example 1. Among them, styrene-butadiene rubber is 100phr, and clay is 10phr. Tested according to national standards, the mechanical properties of composite materials are shown in Table 1, and the stress-strain curves are shown in figure 1 Curve (b) in.

Embodiment 3

[0068]The difference from Example 1 is that the mass of hydrochloric acid used to acidify γ-methacryloxypropyltrimethoxysilane in this example is 0.40 g, so that the concentration of hydrogen ions in the solution is 0.017 mol / L. Other vulcanization aids and implementation process are identical with example 1. Among them, styrene-butadiene rubber is 100phr, and clay is 10phr. Tested according to national standards, the mechanical properties of composite materials are shown in Table 1, and the stress-strain curves are shown in figure 1 Curve (c) in.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com