A kind of polyurethane/polyvinyl acetate hybrid emulsion and preparation method thereof

A technology of polyvinyl acetate and polyurethane, which is applied in the field of architectural coatings or adhesives, can solve the problems of failing to realize the organic combination of polyurethane groups and polyvinyl acetate, and achieve the purpose of overcoming poor stability, improving stability, and improving phase Capacitive and Dispersive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of polyurethane / polyvinyl acetate hybrid emulsion of the present invention comprises the following steps:

[0048] 1. Preparation of double bond-containing polyurethane oligomer monomer

[0049] a: Under normal pressure at 50-90°C, add diols containing hydrophilic groups, macromolecular diols and polyether triols sequentially into a polymerization kettle with a stirrer and a condenser, and Continue to stir for 10-40 minutes until it is completely dissolved;

[0050] b: Add isocyanate to the mixture in step a, and keep the temperature at 60-90°C, react for 1-3 hours, then keep it warm for 10-50 minutes, and add metal catalyst T-12 to complete the reaction;

[0051] c: Add monohydroxyl-containing unsaturated monomers to the mixture in step b, and keep the temperature at 60-90°C, and react for 0.5-2 hours;

[0052] d: adding a chain extender to the mixture in step c, and reacting for 10-40 minutes to obtain a double bond-containing polyurethane oli...

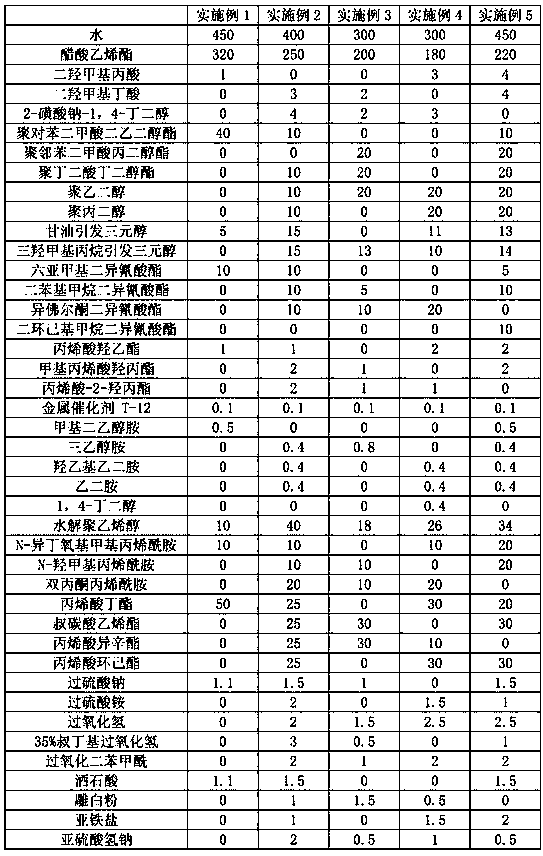

Embodiment 1

[0064] The polyurethane / polyvinyl acetate hybrid emulsion of the present invention comprises water, vinyl acetate, dimethylol propionic acid, polyethylene terephthalate, glycerin initiating trihydric alcohol, hexamethylene diisocyanate, Hydroxyethyl Acrylate, Metal Catalyst T-12, Methyldiethanolamine, Hydrolyzed Polyvinyl Alcohol, N-Isobutoxymethacrylamide, Butyl Acrylate, Sodium Persulfate, Tartaric Acid. The contents of the above components are calculated in parts by mass: 450 parts of water, 320 parts of vinyl acetate, 1 part of dimethylol propionic acid, 40 parts of polyethylene terephthalate, 5 parts of glycerin initiating triol 10 parts of hexamethylene diisocyanate, 1 part of hydroxyethyl acrylate, 0.1 part of metal catalyst T-12, 0.5 parts of methyldiethanolamine, 10 parts of hydrolyzed polyvinyl alcohol, N-isobutoxymethacrylamide 10 parts, 50 parts of butyl acrylate, 1.1 parts of sodium persulfate, 1.1 parts of tartaric acid.

[0065] The preparation method of polyur...

Embodiment 2

[0081] The polyurethane / polyvinyl acetate hybrid emulsion of the present invention comprises water, vinyl acetate, dimethylol butyric acid, 2-sodium sulfonate-1,4-butanediol, polyethylene terephthalate , polybutylene succinate, polyethylene glycol, polypropylene glycol, glycerin initiated triol, trimethylolpropane initiated triol, hexamethylene diisocyanate, diphenylmethane diisocyanate, isofor Alone diisocyanate, hydroxyethyl acrylate, 2-hydroxypropyl acrylate, metal catalyst T-12, triethanolamine, hydroxyethylethylenediamine, ethylenediamine, hydrolyzed polyvinyl alcohol, N-isobutoxymethyl Acrylamide, N-Methylolacrylamide, Diacetone Acrylamide, Butyl Acrylate, Vinyl Tertiary Carbonate, Isooctyl Acrylate, Cyclohexyl Acrylate, Ammonium Persulfate, Hydrogen Peroxide, Tert-Butyl Hydroperoxide , Dibenzoyl peroxide, tartaric acid, white powder, ferrous salt, sodium bisulfite.

[0082] The contents of the above components are calculated in parts by mass: 400 parts of water, 250 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com