Graphene oxide loaded copper sulfide composite material preparation method

A composite material, graphene technology, applied in copper sulfide, chemical instruments and methods, carbon compounds, etc., can solve the problems of complex preparation methods and high energy consumption, and achieve high phase purity, easy commercial production, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

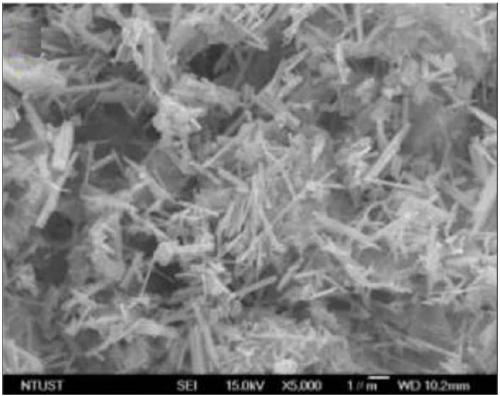

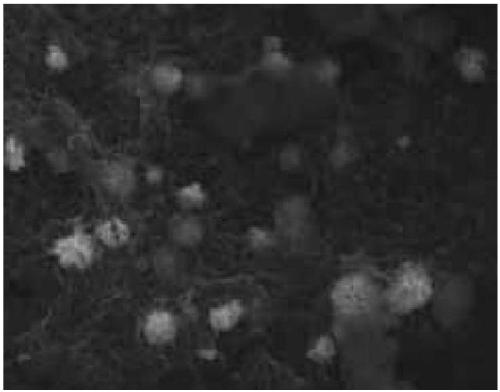

Image

Examples

Embodiment 1

[0033] In the present embodiment, graphene oxide loaded copper sulfide composite material is realized according to the following steps:

[0034] (1) Weigh 1g graphene oxide, 1g copper nitrate and 1g sodium sulfide and dissolve in ethanol solvent, then transfer the solution to a sealed beaker, stir on a magnetic stirrer, the stirring rate is 350rpm, after stirring for 6h, Promptly make mixed solution;

[0035] (2) Transfer the mixed solution obtained in step (1) to a hydrothermal reaction kettle, and then place the hydrothermal reaction kettle in an oven for hydrothermal reaction. The temperature of the oven is set at 160° C., and the reaction time is 3 hours;

[0036] (3) The hydrothermal reaction product obtained in step (2) is subjected to centrifugal cleaning in a centrifuge, the centrifugal speed is 6000rpm, the number of centrifugals is 8 times, and the centrifugal solvent is ultrapure water; then the product is placed in a drying oven to dry , the drying temperature is ...

Embodiment 2

[0039] In this embodiment, the graphene oxide-supported copper sulfide composite material is realized by the following steps:

[0040] (1) Weigh 8g of graphene oxide, 1g of copper nitrate and 1g of sodium sulfide and dissolve them in ultrapure water, then transfer the solution to a sealed beaker and stir on a magnetic stirrer at a stirring rate of 400rpm, after stirring for 7h , to obtain a mixed solution;

[0041] (2) Transfer the mixed solution obtained in step (1) to a hydrothermal reaction kettle, and then place the hydrothermal reaction kettle in an oven for hydrothermal reaction. The temperature of the oven is set at 200° C., and the reaction time is 10 hours;

[0042] (3) The hydrothermal reaction product obtained in step (2) is subjected to centrifugal cleaning in a centrifuge, the centrifugal speed is 7000rpm, the number of centrifugals is 9 times, and the centrifugal solvent is ethanol; then the product is placed in a drying oven to dry and dry The temperature is 45...

Embodiment 3

[0045] In this embodiment, the graphene oxide-supported copper sulfide composite material is realized by the following steps:

[0046] (1) Weigh 8g of graphene oxide, 4g of copper nitrate and 1g of sodium sulfide and dissolve them in ultrapure water, then transfer the solution to a sealed beaker and stir on a magnetic stirrer at a stirring rate of 500rpm, after stirring for 8h , to obtain a mixed solution;

[0047] (2) Transfer the mixed solution obtained in step (1) to a hydrothermal reaction kettle, and then place the hydrothermal reaction kettle in an oven for hydrothermal reaction. The temperature of the oven is set at 280° C., and the reaction time is 24 hours;

[0048] (3) The hydrothermal reaction product obtained in step (2) is centrifugally cleaned in a centrifuge, the centrifugal speed is 8000rpm, the centrifugal frequency is 10 times, and the centrifugal solvent is ultrapure water or ethanol; then the product is placed in a drying box Drying, the drying temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com