Aircraft propeller feathering pump

A technology for feathering pumps and propellers, which is applied in the field of aircraft propeller design to achieve the effect of reducing control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

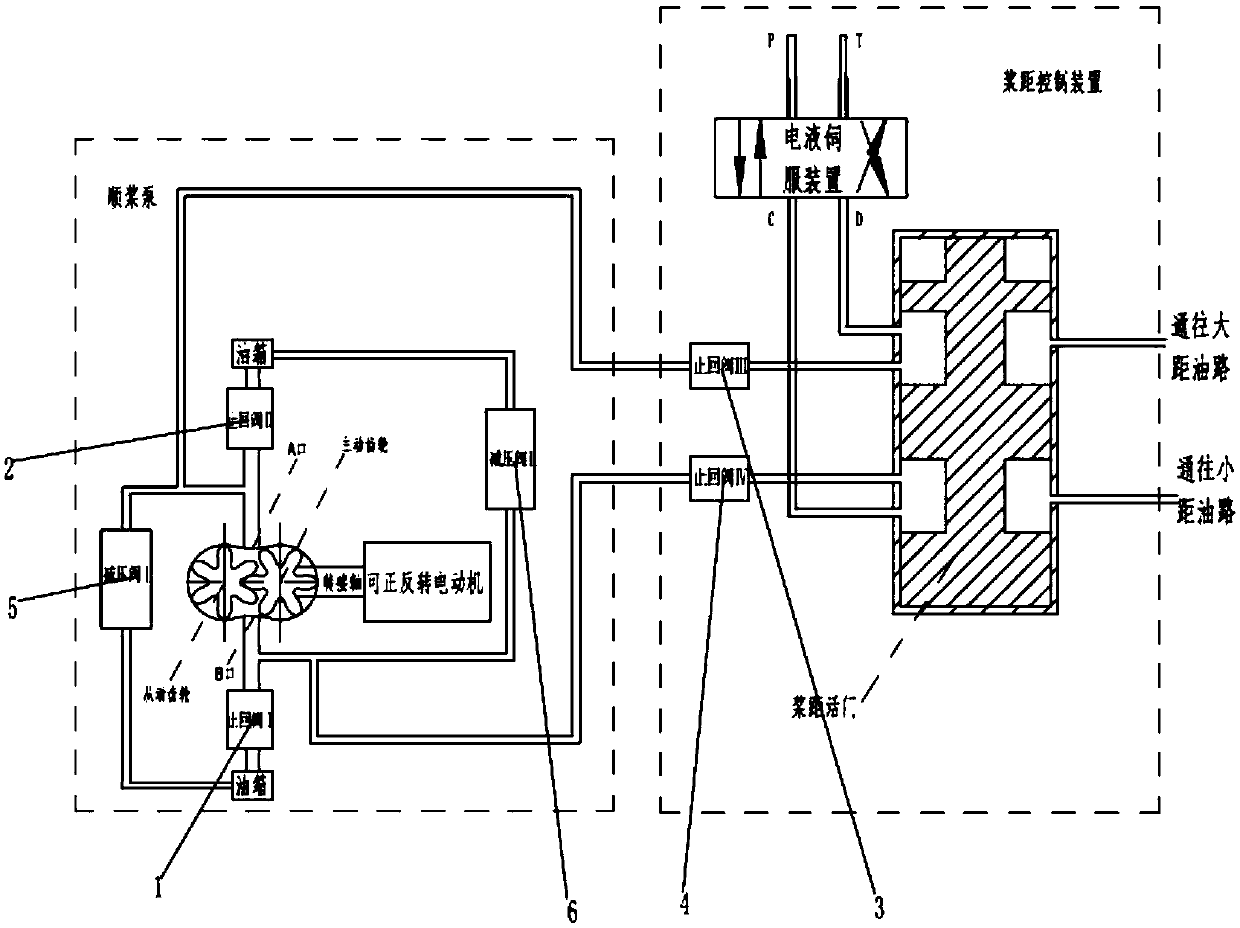

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

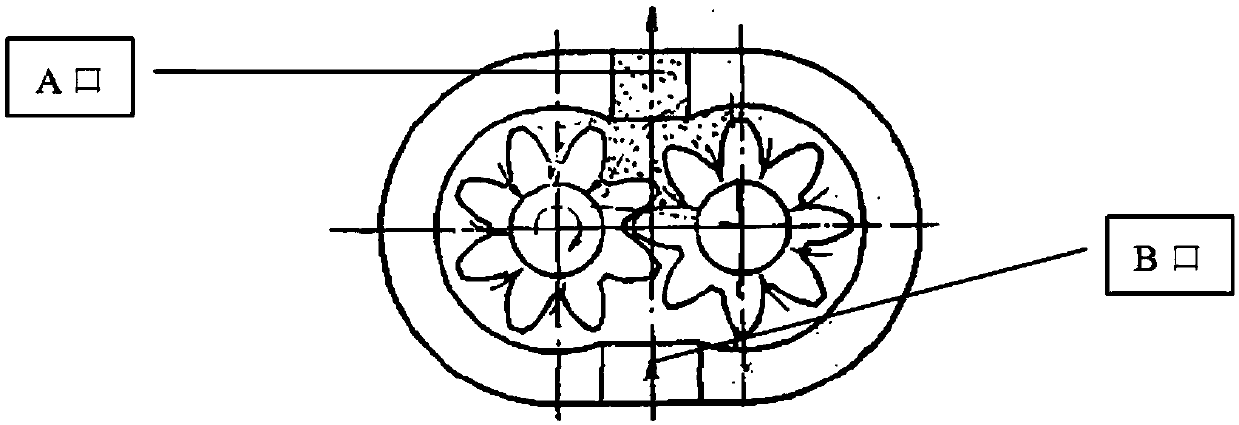

[0017] see figure 2 , in order to meet the needs of the feathering device of the present invention to realize feathering back, the two ports A and B of the gear pump are required to be able to feed oil from the fuel tank. Check valves are installed on ports B and B respectively.

[0018] Assume that when the output shaft of the driving motor rotates forward (assuming that it is facing the motor mounting seat, the motor output shaft rotates counterclockwise), the driving gear in the driving gear pump rotates, the lubricating oil enters from port B, and the gear pump pressurizes the lubricating oil to form a high pressure Lubricating oil, high-pressure lubricating oil flows out from A port, adjusts the pressure of the lubricating oil through the pressure reducing valve, enters the pitch control device, enters the pitch valve throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com