Lubricating oil valve controlled by bypass air

A technology of lubricating oil and valves, which is applied in the direction of engine lubrication, lubricating oil control valves, lubricating parts, etc., can solve problems such as unsatisfactory, unmatched control of one-way valves, etc., achieve high reliability, reduce structural weight, and expand The effect of controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

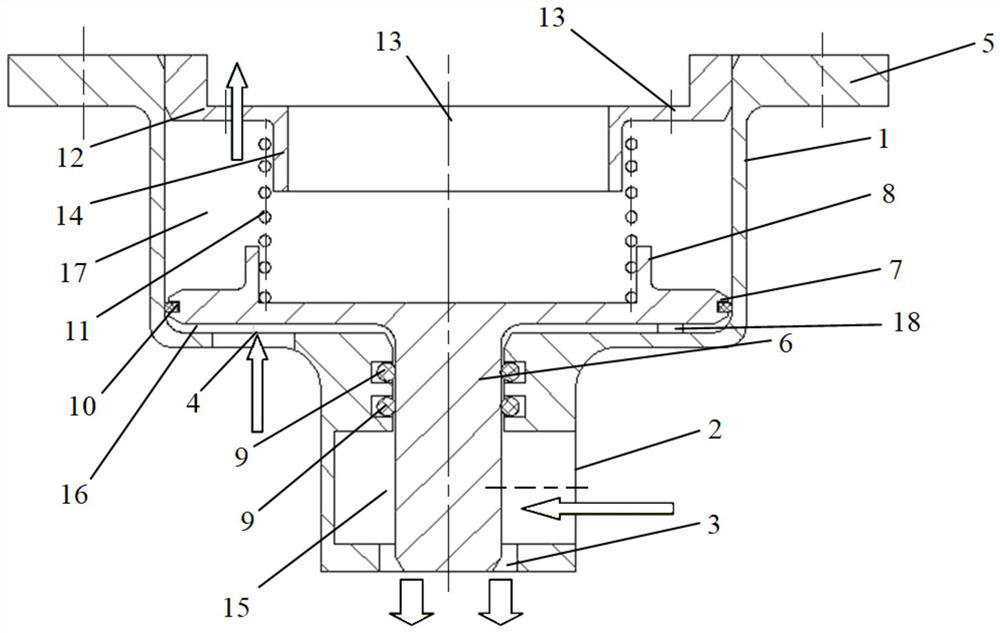

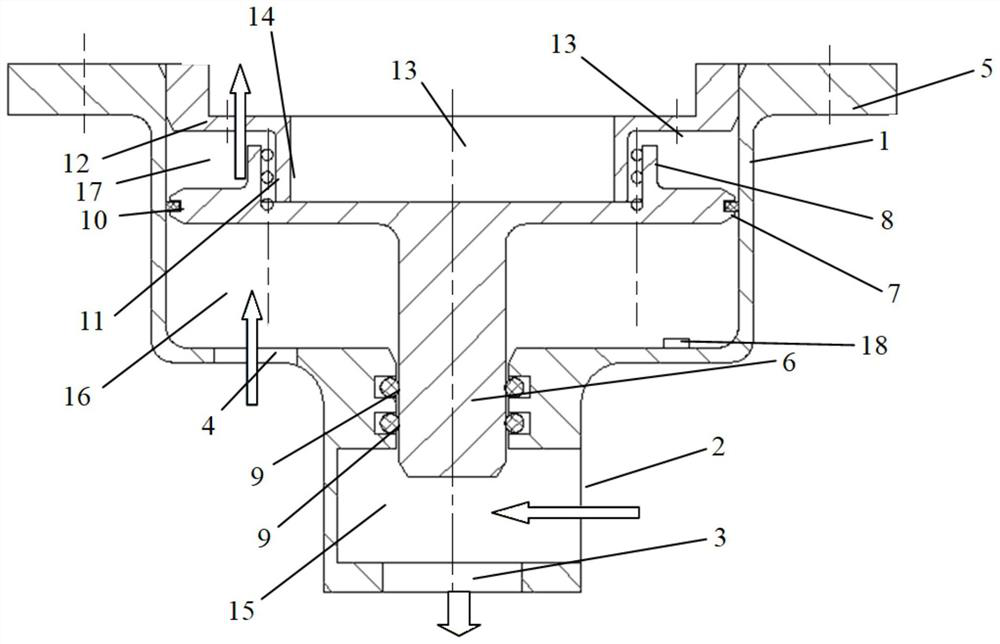

[0067]like figure 1 The throttling state of the lubricating valve controlled by external air and figure 2 As shown in the non-throttling state of the lubricating oil valve controlled by external air, the oil valve controlled by external air provided by this application mainly includes: valve housing 1, T-shaped valve core 6, plug cover 12, spring 11, etc. .

[0068] The valve housing 1 has an accommodating cavity, on the side of the valve housing 1 there is an oil inlet 2 perpendicular to the axis of the valve housing, on the lower end of the valve housing 1 there is an oil outlet 3 arranged along the axis of the valve housing, The lubricating oil outlet 3 communicates with the lubricating oil inlet 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com