A kind of automatic printing method of printer

An automatic printing and printer technology, applied in printing devices, printing, etc., can solve problems such as paper jams, and achieve the effects of ensuring printing effects, avoiding paper jams, and ensuring heating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further detailed explanation through specific implementation mode below:

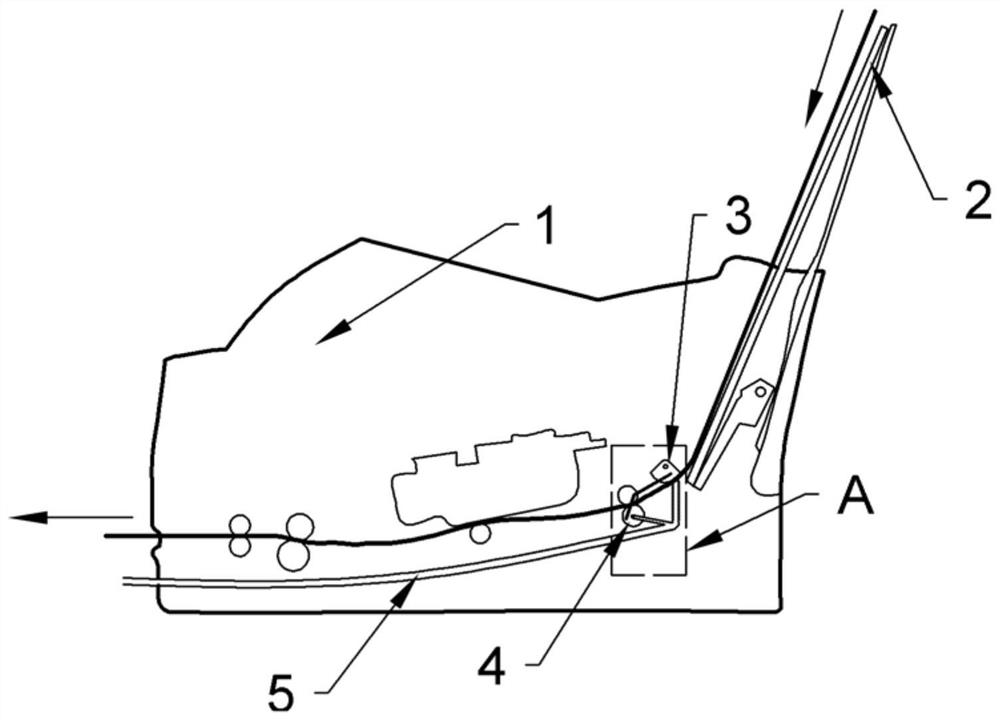

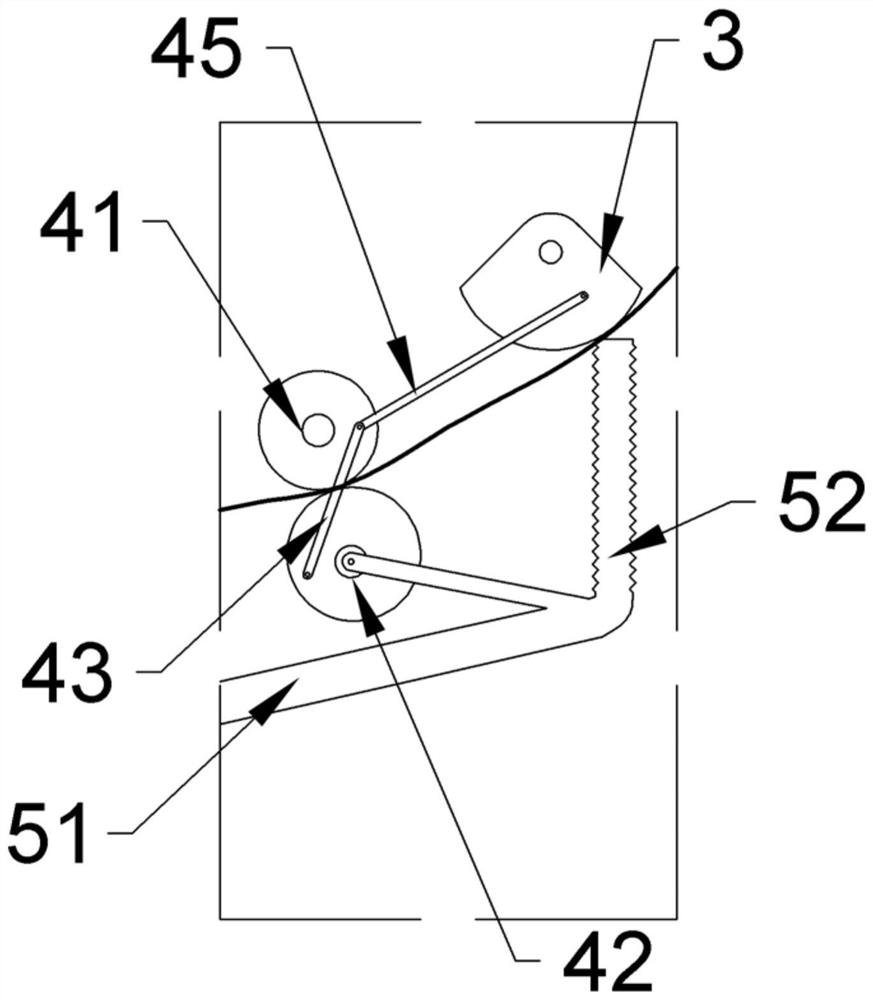

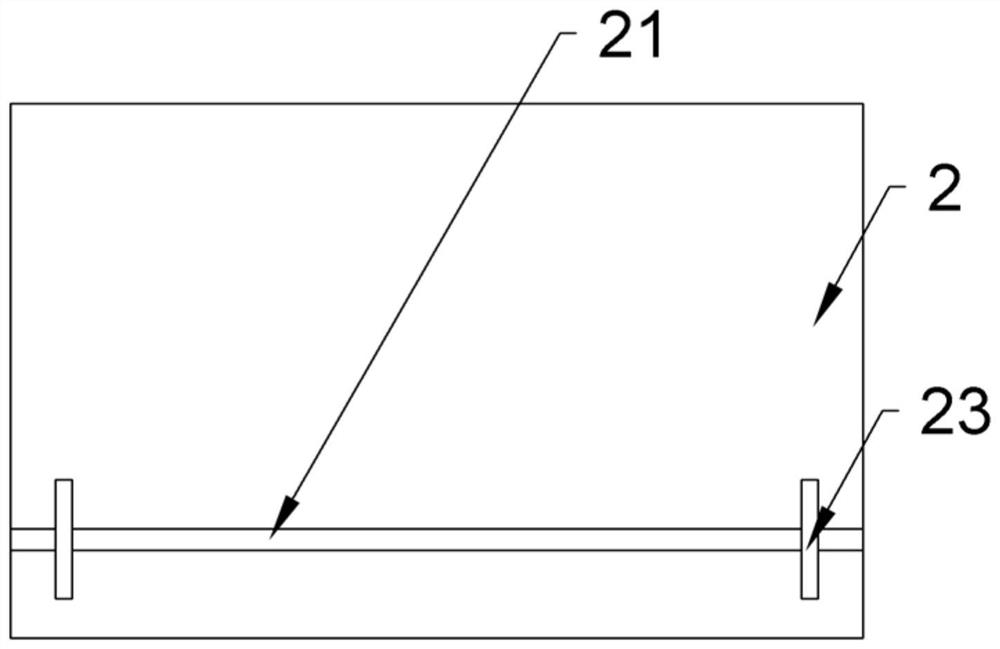

[0025] The reference signs in the drawings of the specification include: body 1, paper feeding board 2, chute 21, limit block 23, paper feeding cam 3, paper feeding pair roller 4, second rotating roller 41, first rotating roller 42, second rotating roller A connecting rod 43 , a second connecting rod 45 , a heat conduction component 5 , an air duct 51 , and a bellows 52 .

[0026] The printing equipment that the automatic printing method of a kind of printer of the present invention adopts is as figure 1 As shown, the main body 1 is included, and one end of the main body 1 is equipped with a paper delivery box, and the other end is provided with a paper outlet. Specifically, in this embodiment, the right end of the main body 1 is equipped with a paper delivery box, and the left end is provided with a paper outlet. The box includes a paper feeding plate 2 for putting paper, wherein: the paper fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com