Forming device

A molding device and molding part technology, which can be applied to household appliances, other household appliances, flat products, etc., can solve the problems of poor optical performance, equipment quality degradation, and uneven thickness of film materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

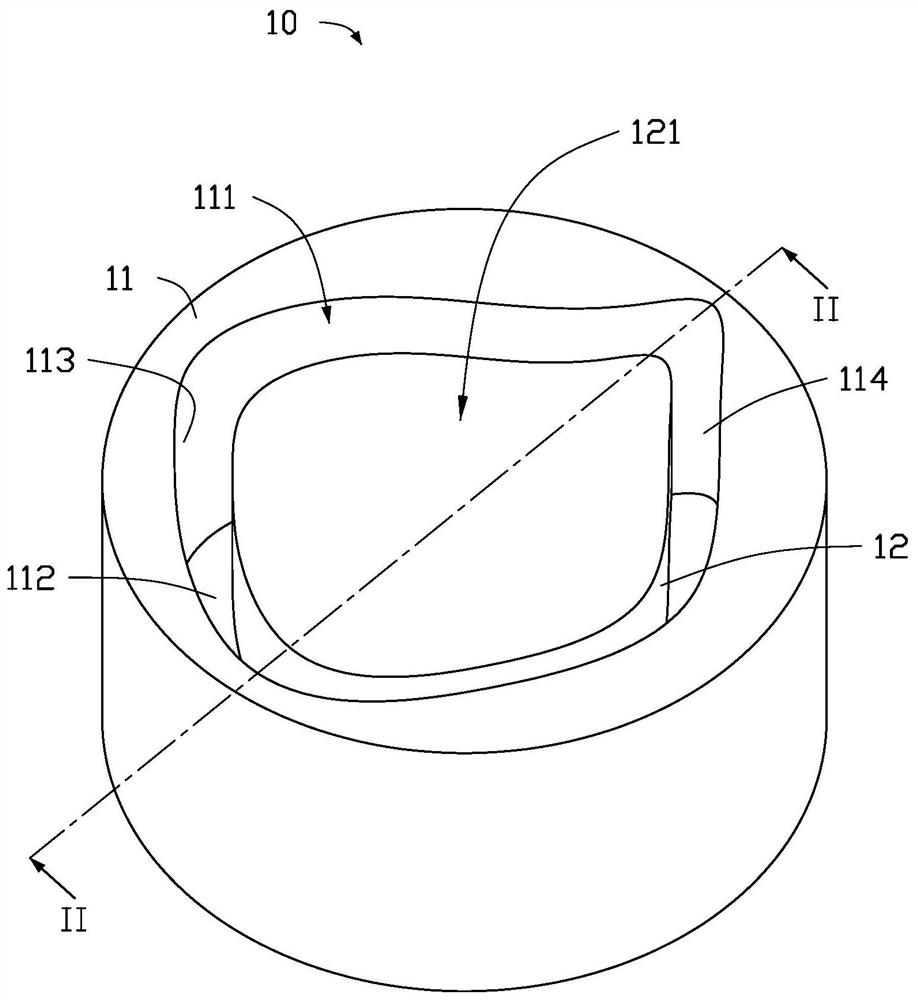

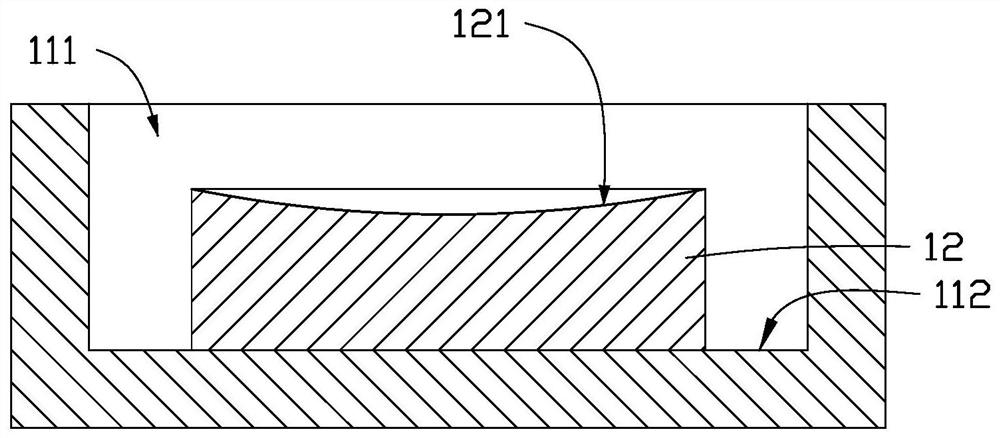

[0018] see figure 1 , the molding device 10 provided in this embodiment includes a bearing part 11 and a molding part 12 combined on the bearing part 11 .

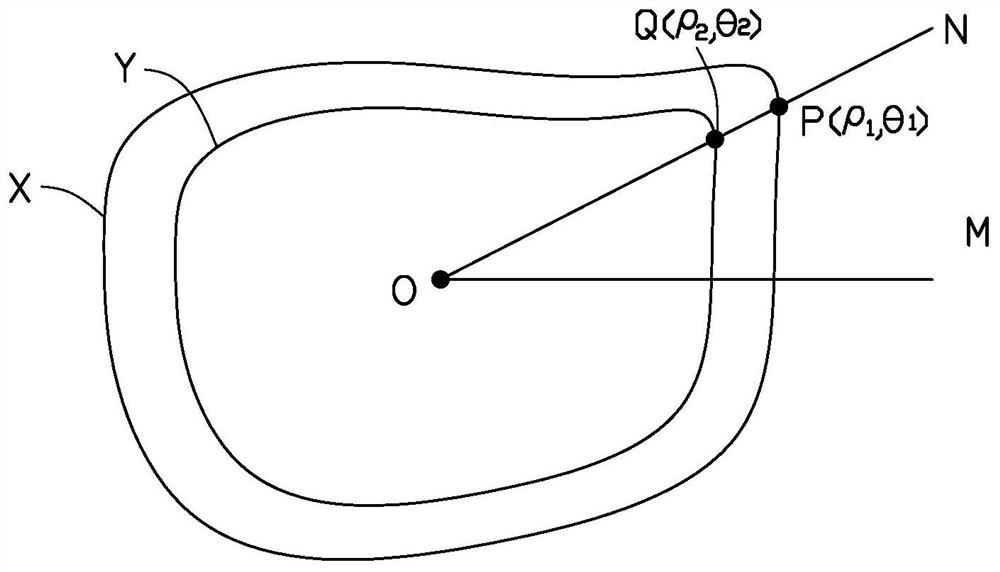

[0019] like figure 1 As shown, a groove 111 is disposed on the carrying portion 11, and the groove 111 is used for accommodating the product to be formed. The groove 111 has a bottom wall 112 , a side wall 113 connected to the bottom wall 112 and an opening 114 away from the bottom wall 112 . The forming portion 12 is disposed on the bottom wall 112 of the groove 111 , and the forming portion 12 is accommodated in the groove 111 . The forming portion 12 is spaced apart from the sidewall 113 of the groove 111 .

[0020] In this embodiment, the carrying part 11 and the forming part 12 are integrally formed, and the integrated forming methods may include but not limited to: 3D printing, injection molding, and the integrated forming method is more efficient. In another embodiment, the forming part 12 is combined with the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com