Low-carbon steel high-speed MAG welding active agent and using method thereof

An active agent and low-carbon steel technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of poor weld formation, etc., to eliminate weld undercut, promote popularization and application, and improve wettability and spreading sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

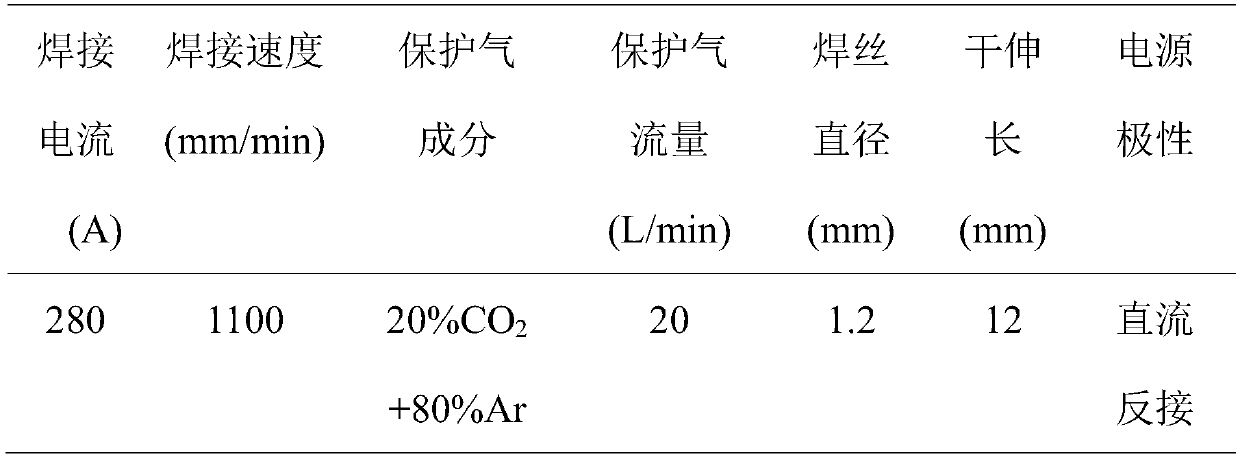

[0035] Welding steps in this embodiment: Step 1: Use an electronic scale to carry out activator batching according to the weight ratio to make an activator for low-carbon steel high-speed MAG welding, wherein the components are distributed by weight percentage, respectively CaF 2: 40%, MgF 2 : 20%, SiO 2 : 5%, TiO 2 : 25%, Cr 2 o 3 : 6%, CeO 2 : 4%, the powder particle size of each component is less than 200 mesh. Put the powders of each component together in a ball mill for 30 minutes to make them fully mixed and become the activator powder for high-speed MAG welding of low-carbon steel;

[0036] Step 2: The base material is a low-carbon steel workpiece with a thickness of 3 mm. Before welding, the surface of the low-carbon steel workpiece is mechanically polished until a metallic luster appears, and the surface of the low-carbon steel workpiece is wiped with acetone to remove surface oil stains;

[0037] Step 3: Mix the activator powder prepared in the first step for h...

Embodiment 2

[0043] Welding steps in this embodiment: Step 1: Use an electronic scale to carry out activator batching according to the weight ratio to make an activator for low-carbon steel high-speed MAG welding, wherein the components are distributed by weight percentage, respectively CaF 2 : 35%, MgF 2 : 17%, SiO 2 : 8%, TiO 2 : 27%, Cr 2 o 3 : 8%, CeO 2 : 5%, the powder particle size of each component is less than 200 mesh. Put the powders of each component together in a ball mill for 30 minutes to make them fully mixed and become the activator powder for high-speed MAG welding of low-carbon steel;

[0044] Step 2: The base material is a low-carbon steel workpiece with a thickness of 3 mm. Before welding, the surface of the low-carbon steel workpiece is mechanically polished until a metallic luster appears, and the surface of the low-carbon steel workpiece is wiped with acetone to remove surface oil stains;

[0045] Step 3: Mix the activator powder prepared in the first step for ...

Embodiment 3

[0048] Welding steps in this embodiment: Step 1: Use an electronic scale to carry out activator batching according to the weight ratio to make an activator for low-carbon steel high-speed MAG welding, wherein the components are distributed by weight percentage, respectively CaF 2 : 30%, MgF 2 : 15%, SiO 2 : 10%, TiO 2 : 30%, Cr 2 o 3 : 9%, CeO 2 : 6%, the powder particle size of each component is less than 200 mesh. Put the powders of each component together in a ball mill for 30 minutes to make them fully mixed and become the activator powder for high-speed MAG welding of low-carbon steel;

[0049] Step 2: The base material is a low-carbon steel workpiece with a thickness of 3 mm. Before welding, the surface of the low-carbon steel workpiece is mechanically polished until a metallic luster appears, and the surface of the low-carbon steel workpiece is wiped with acetone to remove surface oil stains;

[0050] Step 3: Mix the activator powder prepared in the first step for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com