Side body outer board forming die assembly and automobile production line

A technology for forming molds and side wall outer panels, applied in the field of automobile manufacturing, can solve problems such as difficulty in realizing common-mode production, and achieve the effects of saving development costs, occupying small space, and shortening development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments and features in the embodiments of the present invention can be combined with each other. Wherein, unless stated otherwise, the orientation words used in the present invention such as "up, down, left, and right" generally refer to up, down, left, and right as shown in the accompanying drawings.

[0034] The present invention will be described in detail below with reference to the drawings and in combination with embodiments.

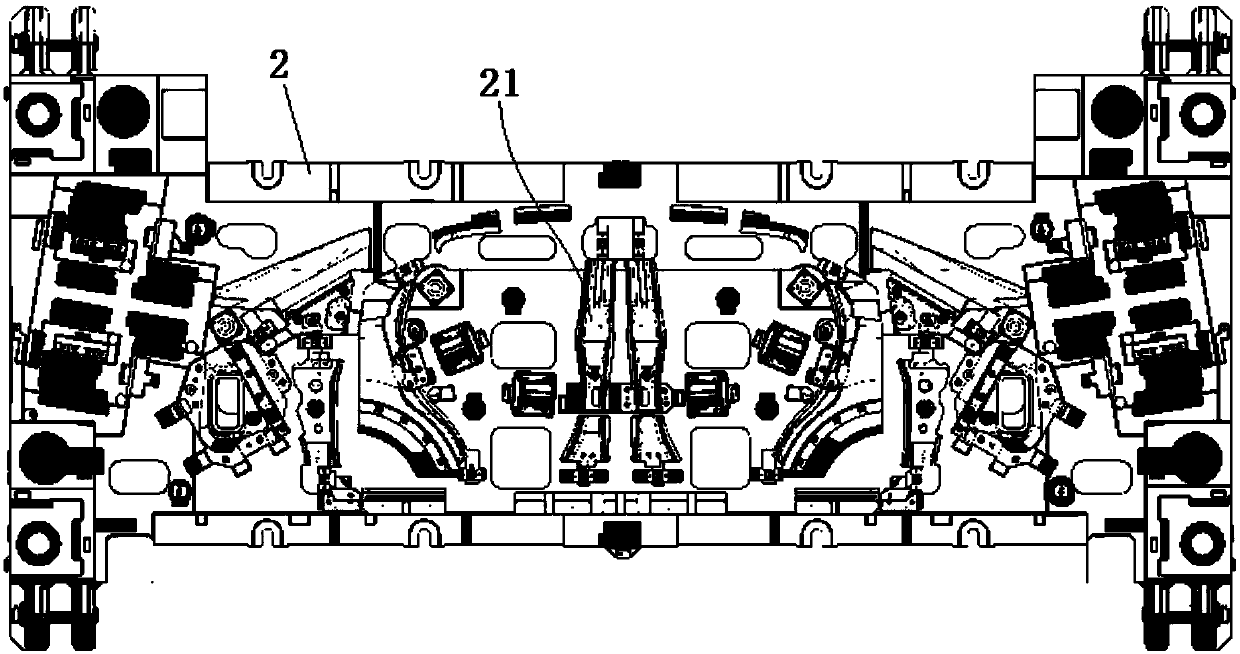

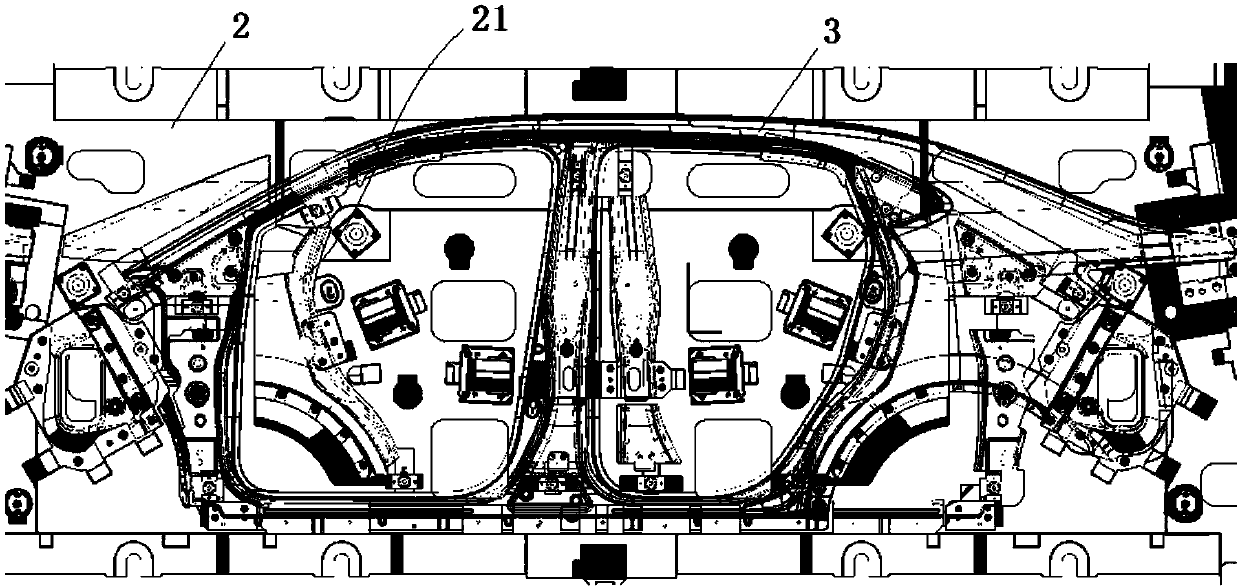

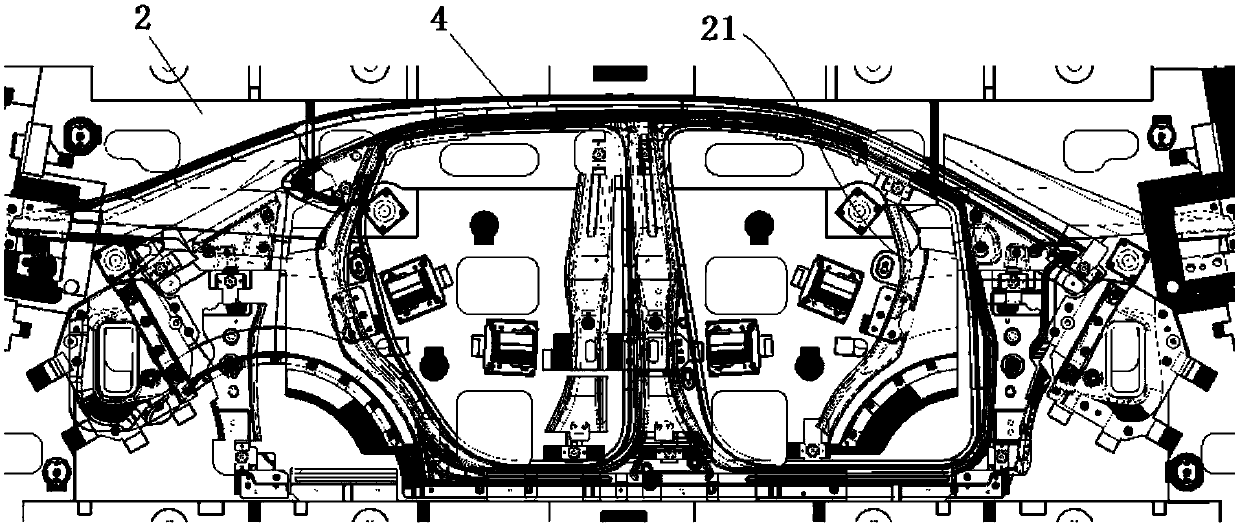

[0035] refer to Figure 1 to Figure 9 As shown, the molding die assembly of the side wall outer panel according to the preferred embodiment of the present invention includes an upper mold 1 and a lower mold 2 arranged opposite to each other, and the side wall outer panel can be placed on the lower mold 2 to pass the upper mold 1 and the lower mold 2. The relative movement of the lower mold 2 realizes forming operations such as edge trimming, punching, and shaping.

[0036] In o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com