Vibration device for vibrating gypsum in denture processing

A vibrating device and gypsum technology, applied in manufacturing tools, medical science, dentistry, etc., can solve the problems of time-consuming, labor-intensive, low efficiency, etc., and achieve the effects of ensuring processing quality, improving density, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

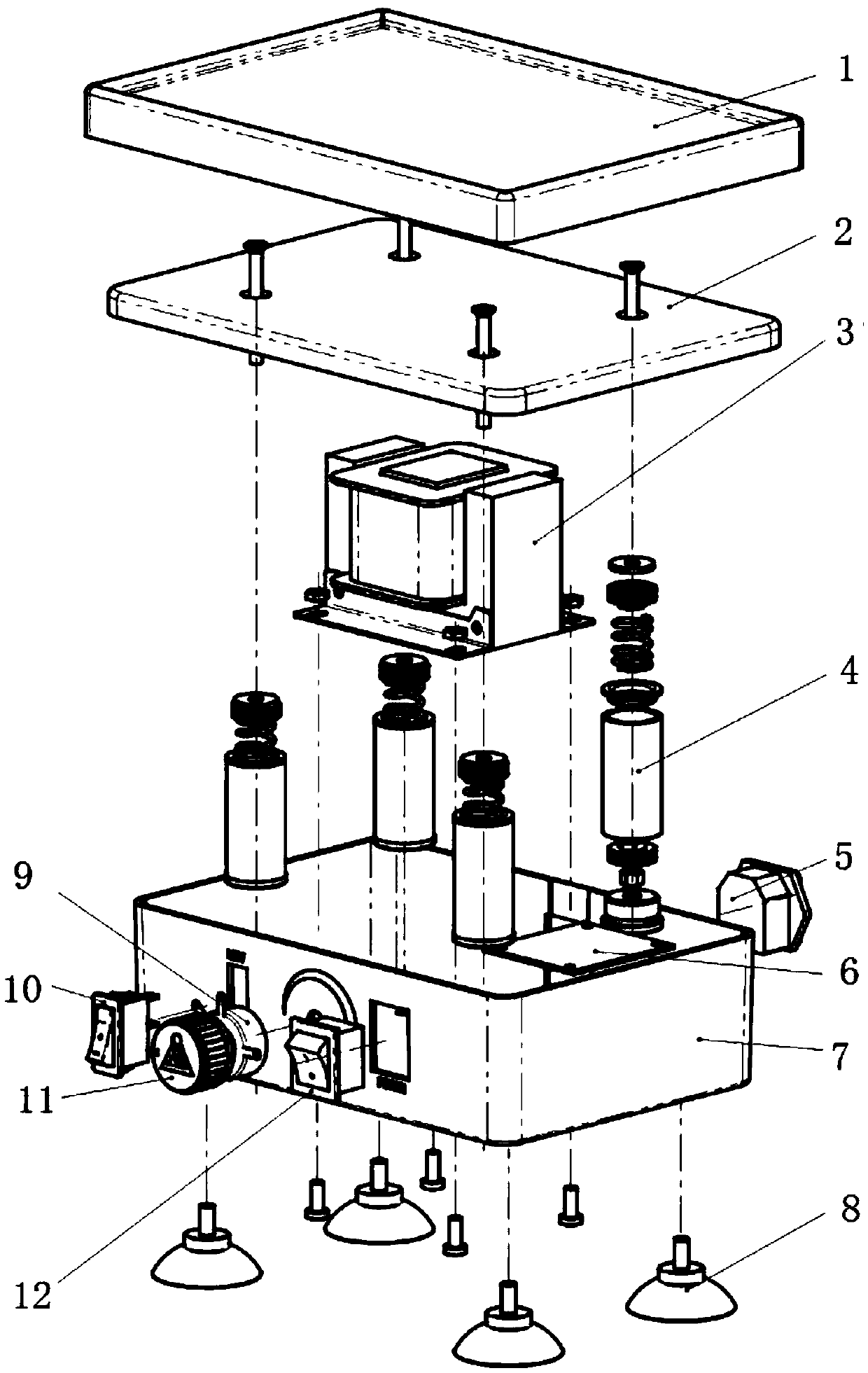

[0016] Such as figure 1 As shown, the present embodiment provides a vibrating device for vibrating gypsum during denture processing, including a vibrating base 7, in which a transformer 3 and four groups of vibrating assemblies 4 are arranged, and an upper end of the vibrating base 7 is provided with Platform 2 is arranged, and described platform 2 is connected with vibrating assembly, is also equipped with power outlet 5, circuit board 7, speed regulating potentiometer 9, three gear switch, knob 11 and power switch 12 on vibrating base 7, in Rubber feet 8 are arranged around the lower end of the vibration base 7 .

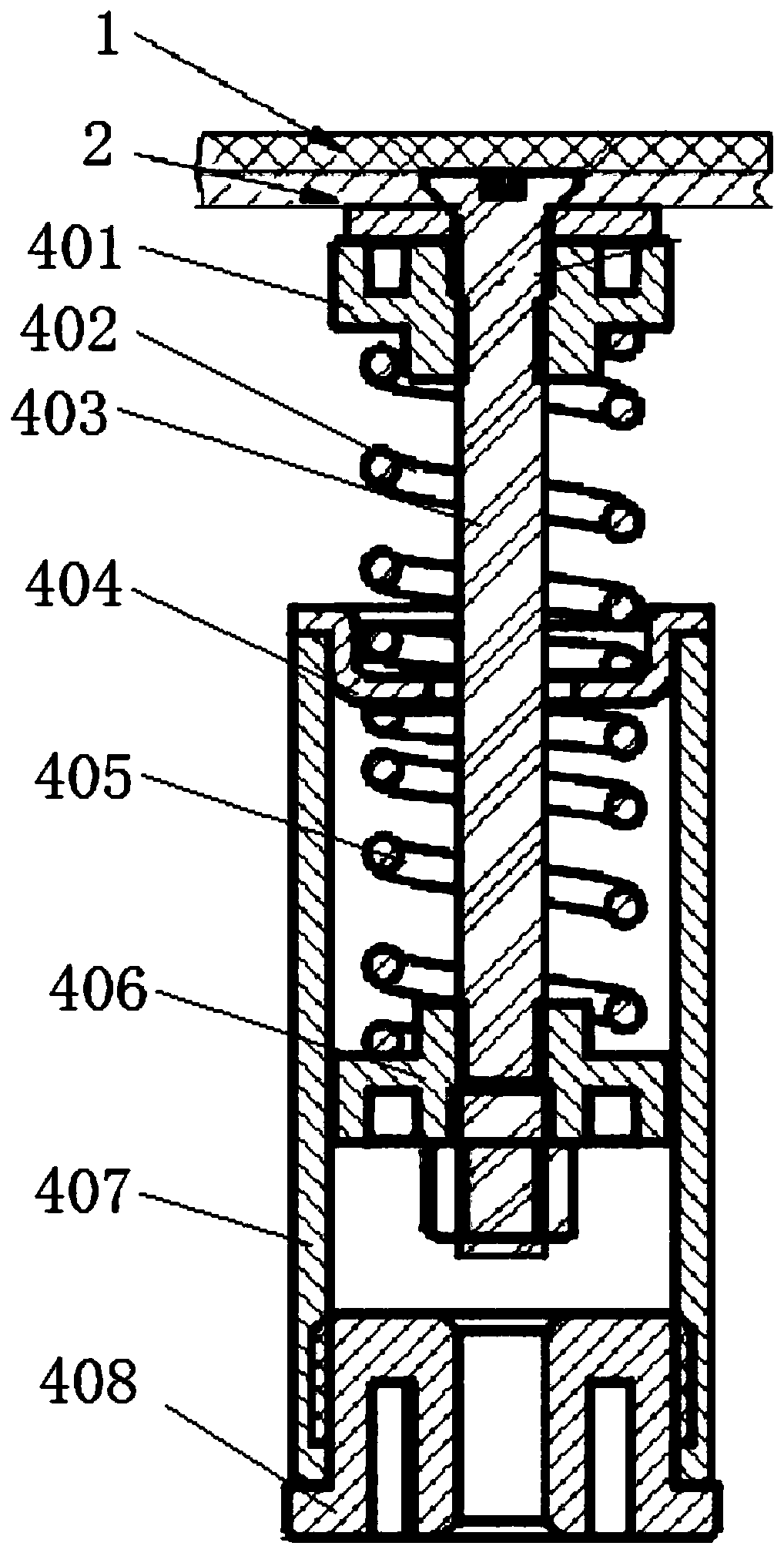

[0017] Such as figure 2 As shown, the vibration assembly includes an upper spring 402, a lower spring 405, a vibrating rod 403 that can move up and down and a cylinder 407, the upper end of the cylinder 407 is fixed with a cap 404, and the lower end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com