Semiconductor sensor and method for manufacturing same

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of excessive film waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0045] Hereinafter, a first embodiment of the present invention will be described with reference to the drawings. The semiconductor sensor of this embodiment is configured as a physical quantity sensor such as a pressure sensor, a flow sensor, or an acceleration sensor, for example.

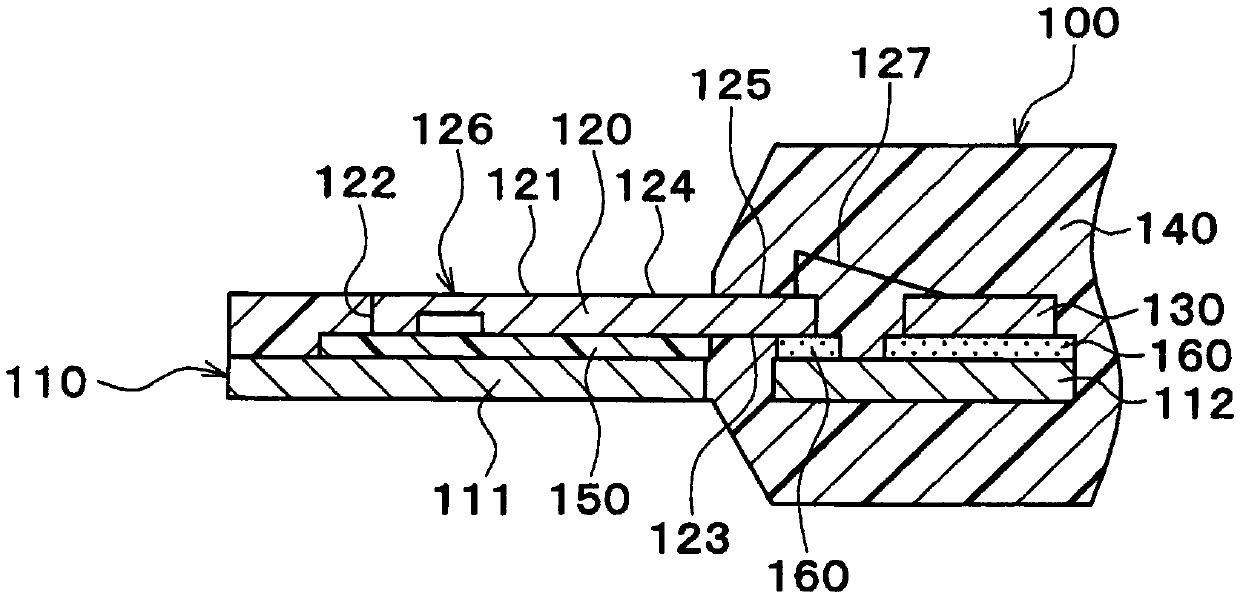

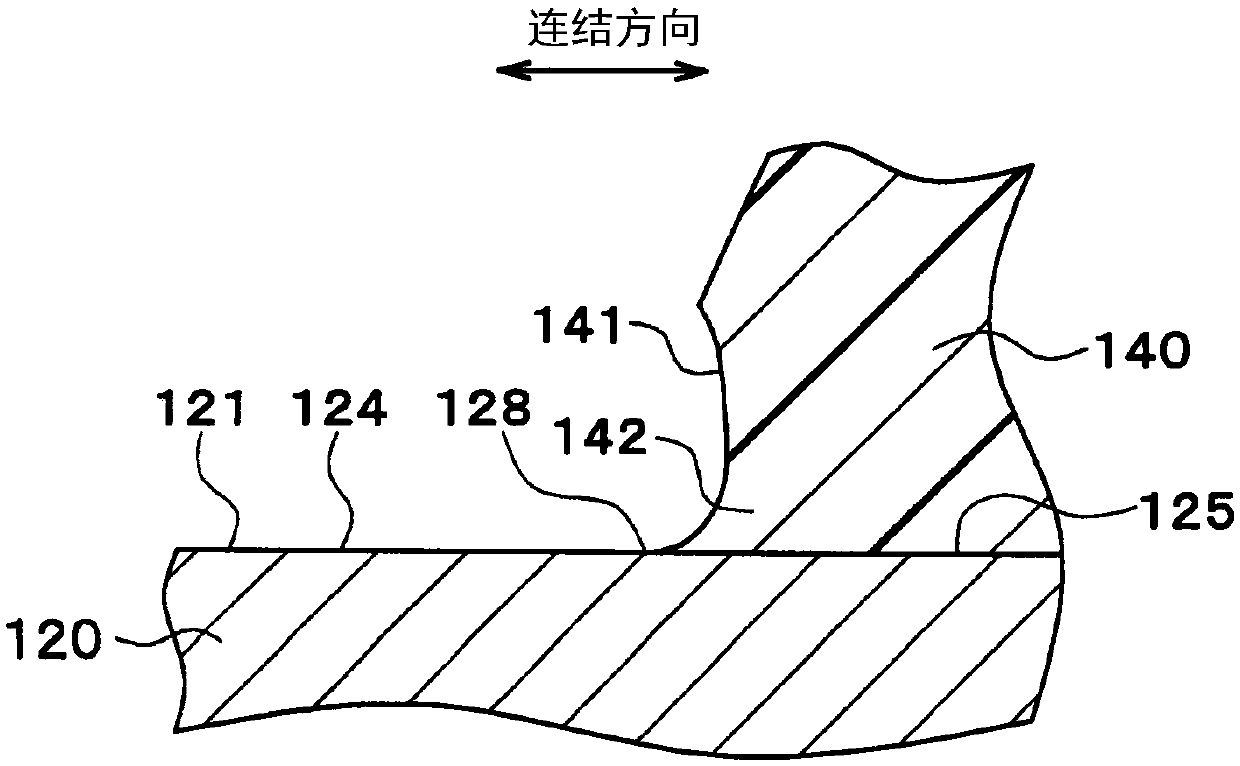

[0046] Such as figure 1 As shown, the semiconductor sensor 100 includes a lead frame 110 , a semiconductor chip 120 , a circuit chip 130 and a cast resin part 140 .

[0047] The lead frame 110 is a metal plate-shaped component, and functions as a fixing portion for the semiconductor chip 120 and the circuit chip 130 and as a terminal for electrically connecting the circuit chip 130 to the outside. The lead frame 110 has a first island 111 , a second island 112 , and a plurality of terminals not shown.

[0048] The first island portion 111 is a component on which the semiconductor chip 120 is mounted. The second island portion 112 is a component on which a part of the semiconductor chip 120 an...

no. 2 Embodiment approach

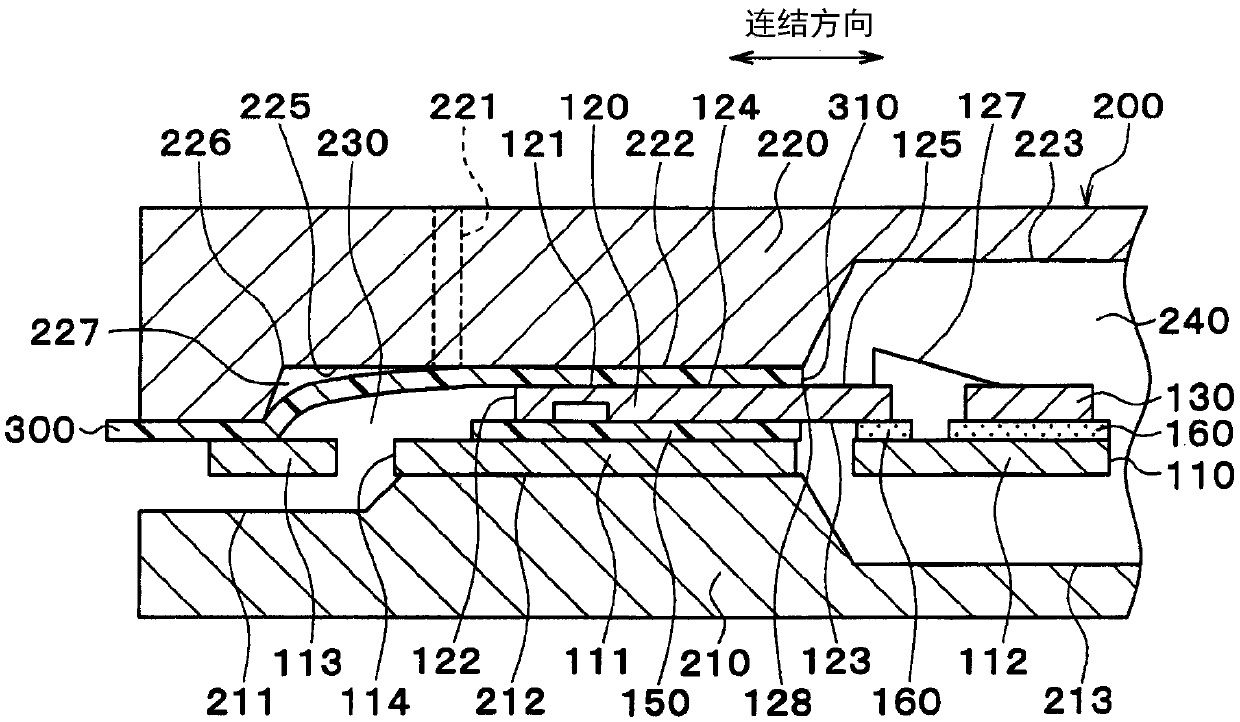

[0082] In this embodiment, differences from the first embodiment will be described. In this embodiment, in the preparatory process, such as Figure 14 As shown, an upper mold 220 having a protrusion 229 is prepared. The protruding portion 229 is a portion of the wall surface 225 of the upper mold 220 facing the gate portion 113 protruding from the step portion 222 facing the first island portion 111 .

[0083] and, if Figure 15 As shown, the resin molding process is performed using the upper mold 220 . The protruding portion 229 of the upper mold 220 makes the height of the space on the side of the gate portion 113 in the first space portion 230 lower than the height of the space on the side of the first island portion 111 . The height of the space corresponds to the width in the direction in which the lead frame 110 is sandwiched between the lower mold 210 and the upper mold 220 . Thus, if Figure 16 As shown, the thickness of the portion corresponding to the gate porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com