Cold- and hot-press fixture formation capacity division machine of soft pack lithium battery

A soft pack lithium battery, cooling and heating technology, applied in the direction of lithium batteries, batteries, secondary batteries, etc., can solve the problems of large footprint, heavy workload of manual handling operations, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

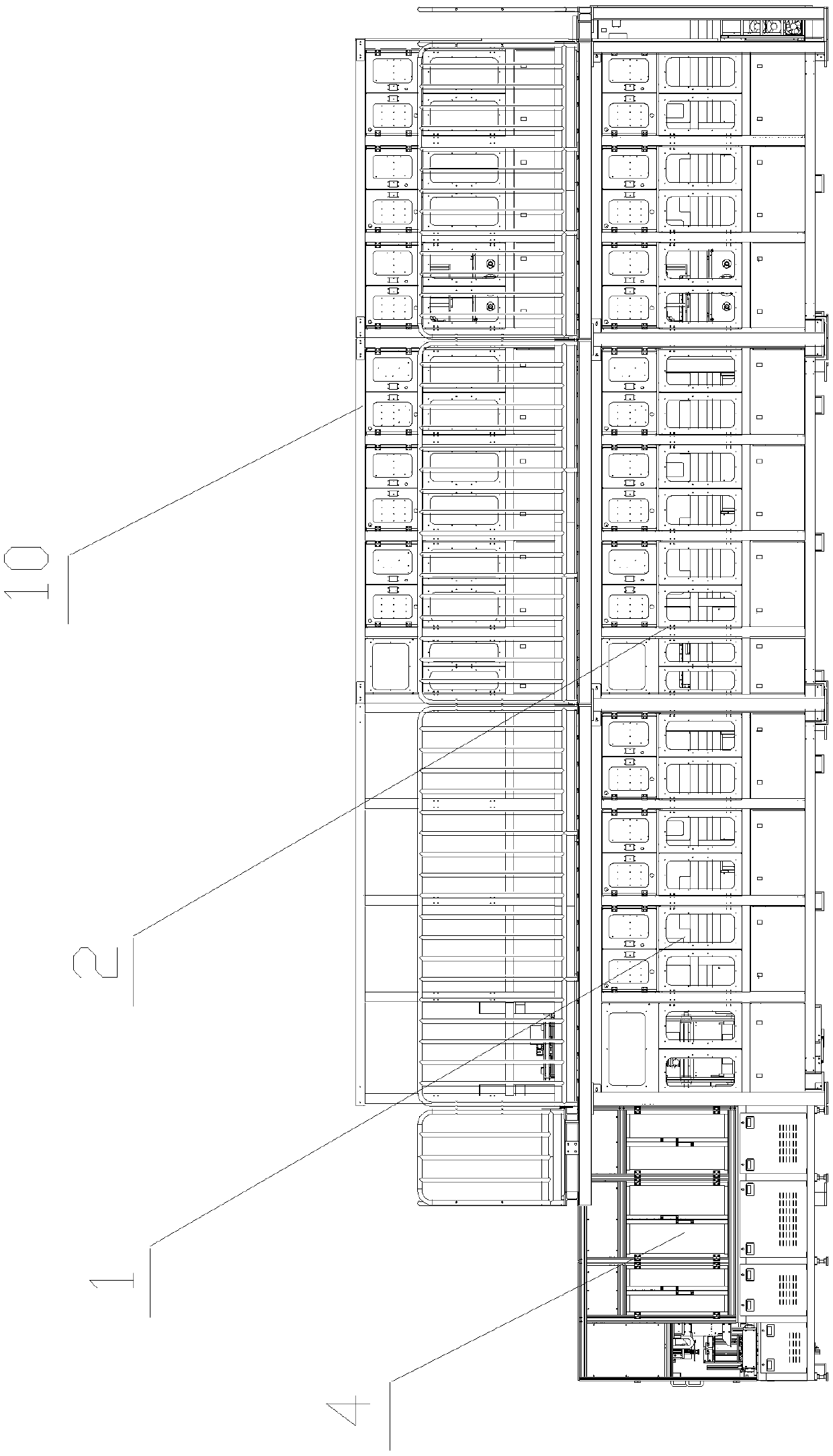

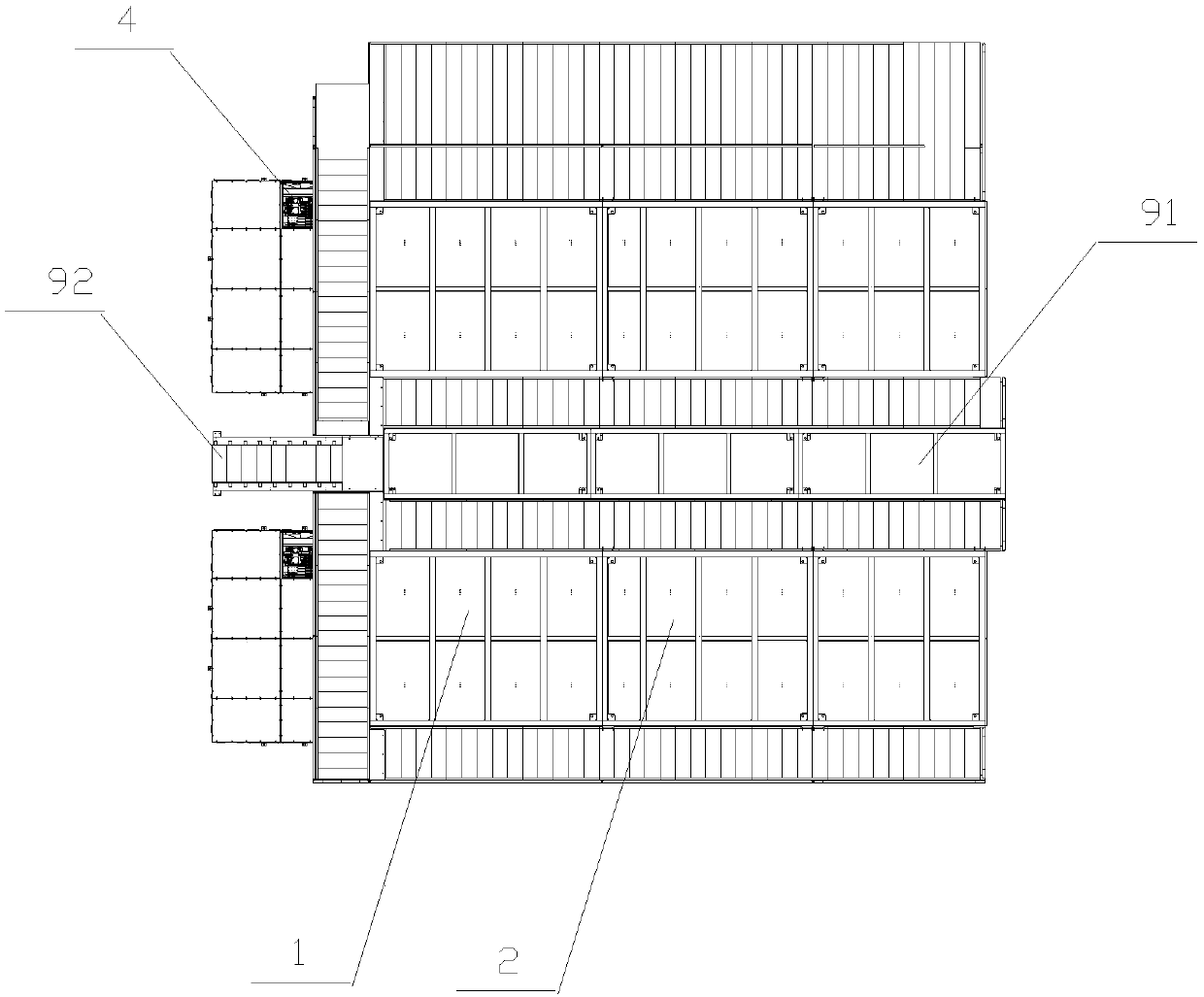

[0063] Embodiment 1 The soft-packed lithium battery cold and hot pressing fixture of the present invention, several sets of volume dividing devices and a maintenance unit 9 for connecting the volume dividing devices, the volume dividing devices are superimposed on each other into a layered structure, And keep the volume dividing device axially parallel; the maintenance unit is installed on the side of the volume dividing device; the volume dividing device includes an outer frame 10, a thermocompression component, a thermocompression fixture unit 1, a cold compression forming fixture unit 2, a charge and discharge The chemical conversion control unit 3, the battery loading and unloading unit 4, the transplanting manipulator unit 5, the production process control detection and safety alarm unit 6, the central controller 7 and the database unit 8; the outer frame 10 is provided with a processing tool for processing batteries The thermocompression component-capacity hot-pressing fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com