High-performance doped lithium manganate positive electrode material and preparation method thereof

A type of lithium manganate and cathode material technology, applied in the field of high-performance doped lithium manganate cathode material and its preparation, can solve the problems of high self-discharge, poor compaction, poor high temperature performance, etc., and achieve the tap density Improved, simple operation, fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

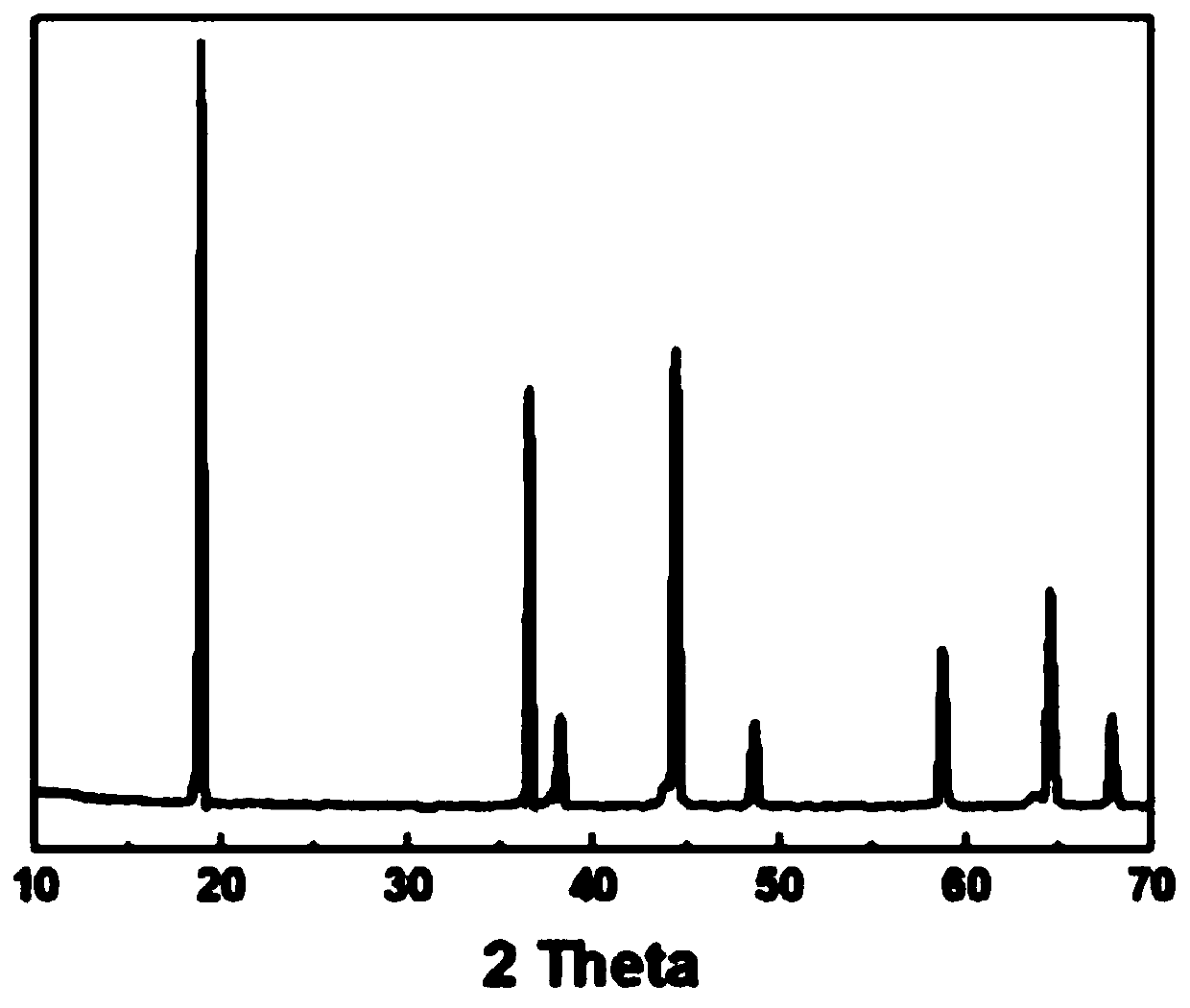

Image

Examples

Embodiment 1

[0025] A high-performance doped lithium manganate cathode material, its chemical formula is Li 1.1 mn 1.8 Al 0.1 Mg 0.1 f 0.1 o 3.9 .

[0026] The preparation method of the cathode material comprises the following steps:

[0027] (1) Weigh MnO in proportion 2 , Li 2 CO 3 And the source compound of doping elements, Li source is LiF, Al source is Al(OH) 3 , Mg source is Mg(OH) 2 , F source is LiF;

[0028] (2) Ball milling and mixing for 0.5h;

[0029] (3) Roasting at 900°C for 10 hours;

[0030] (4) Slowly cool down in the natural state;

[0031] (5) Screening, sampling inspection, and packaging.

Embodiment 2

[0033] A high-performance doped lithium manganate cathode material, its chemical formula is Li 1.12 mn 1.87 Al 0.12 Mg 0.01 f 0.12 o 3. 88 . Its preparation method is similar to Example 1, ball milling and mixing for 3 hours, calcination at 700°C for 10 hours, and other operating conditions are the same as Example 1.

Embodiment 3

[0035] A high-performance doped lithium manganate cathode material, its chemical formula is Li 1.11 mn 1.84 Al 0.11 Mg 0.05 f 0.11 o 3. 84 . Its preparation method is similar to Example 1, ball milling and mixing for 2 hours, calcination at 800°C for 2 hours, and other operating conditions are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com