Locking pump for fast punch sliding-block oil cylinder locking

A technology for punch sliders and oil cylinders, which is applied in fluid pressure actuation devices, servo motors, and fluid pressure actuation system tests. It can solve the problems of high-speed punch cylinder pressure stability, no mandatory lubrication system, and slider and cylinder wear. Overspeed and other problems, to achieve the effect of ingenious design, good pressure holding performance and reduced wear of the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

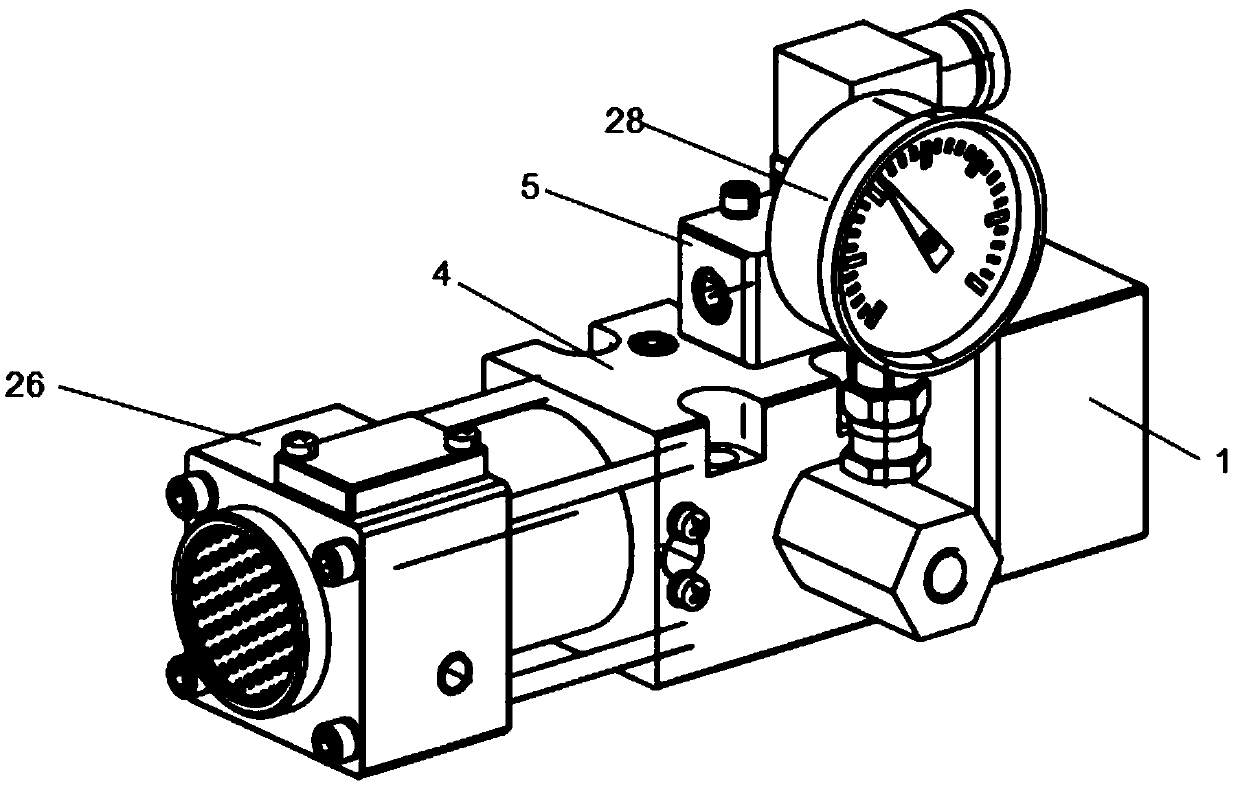

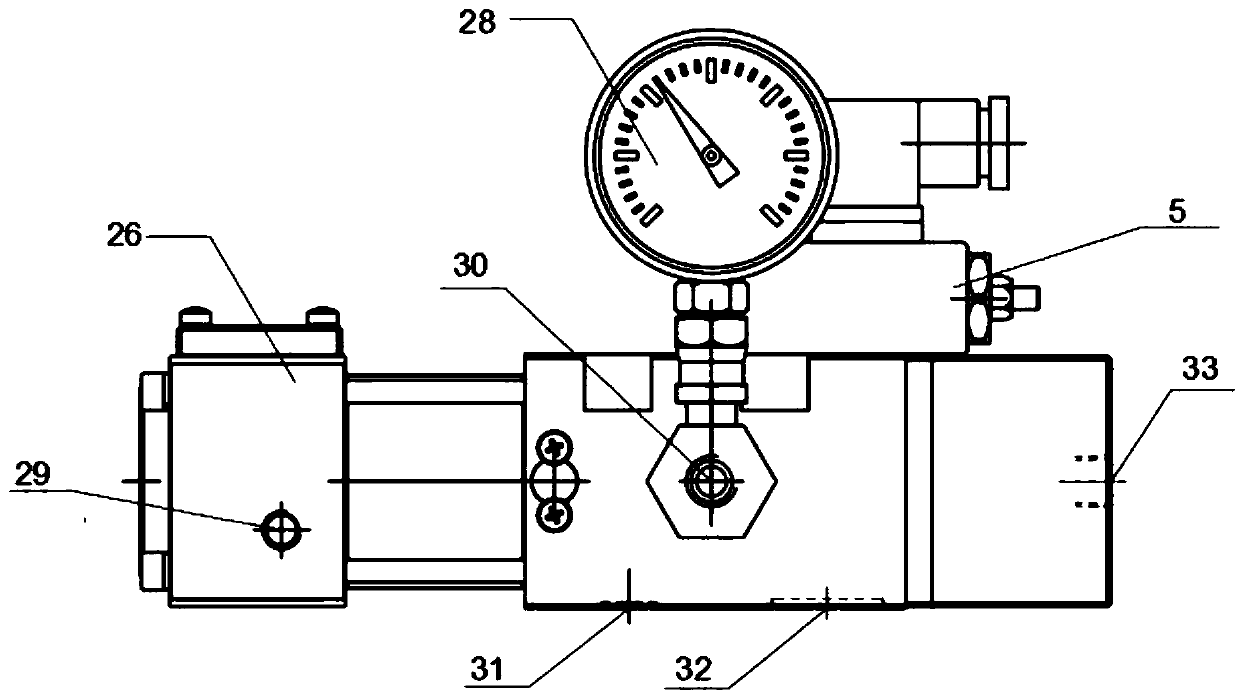

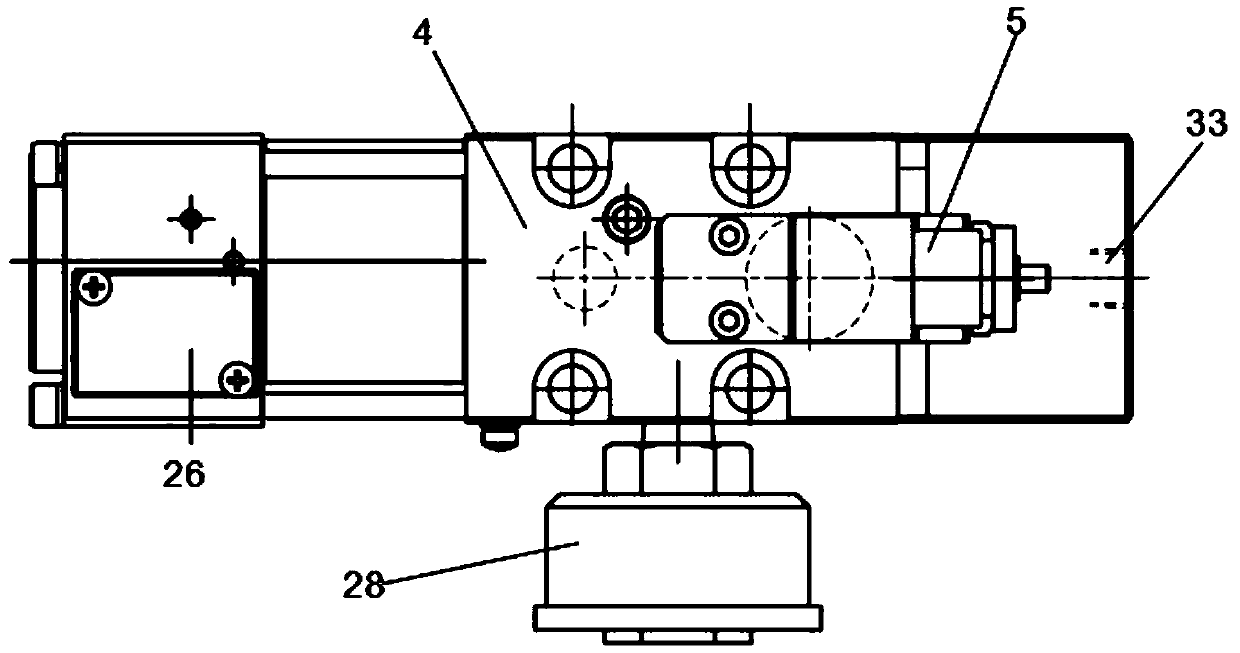

[0026] Embodiment: A locking pump used for fast punching slide block cylinder locking.

[0027] refer to Figure 1 to Figure 5As shown, a locking pump used for fast punching slide block cylinder locking includes: a locking pump housing 4; a first piston 2 installed on the left end side of the locking pump housing 4, and the first piston 2 The right side of the push rod 13 is fixedly installed, and the surface of the push rod 13 is sleeved with a return spring 14, the first piston 2 can drive the push rod 13 to move, and the reset of the first piston 2 is carried out by the return spring 14; Lock the cylinder head 1 on the left end side of the pump housing 4 and wrap the first piston 2, the middle part of the cylinder head 1 is provided with an unloading air supply port 33, and the unloading air supply port 33 communicates with the first piston 2; The unloading check valve 100 on the right side of the first piston 2 is provided with the oil return port 32 at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com