Method for preparing acidic oil by using soapstock

A technology of acidified oil and soapstock, which is applied in the field of preparing acidified oil by using soapstock, can solve the problems of increasing costs, polluting the environment with acidified wastewater, affecting the treatment and utilization of acidified oil, and achieving the goals of reducing sewage, saving production costs, and reducing consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

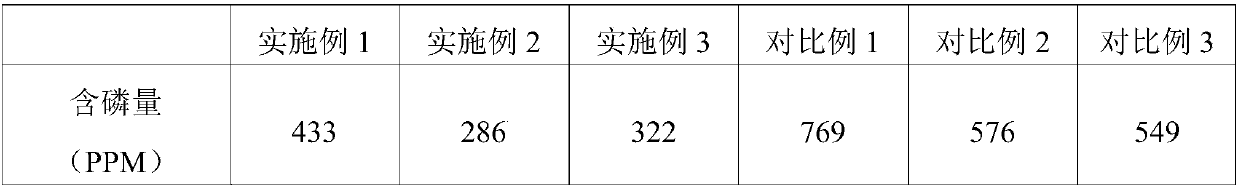

Examples

Embodiment 1

[0017] Heat the soapstock to 90°C, add 30kg of sulfuric acid with a mass fraction of 92.8% to 1 ton of soapstock for primary acidification, precipitate and separate the upper layer of grease to obtain primary acidified oil; heat the primary acidified oil to 90°C, 15 kg of sulfuric acid with a mass fraction of 92.8% was added to the oil for secondary acidification, and the upper layer of oil was precipitated and separated to obtain the acidified oil of this embodiment. In this example, 105 kg of sulfuric acid with a mass fraction of 92.8% was used to produce 1 ton of acidified oil.

Embodiment 2

[0019] Heat the soapstock to 90°C, add 30kg of sulfuric acid with a mass fraction of 92.8% to 1 ton of soapstock for primary acidification, precipitate and separate the upper layer of grease to obtain primary acidified oil; heat the primary acidified oil to 90°C, 30 kg of sulfuric acid with a mass fraction of 92.8% was added to the oil for secondary acidification, and the upper layer of oil was precipitated and separated to obtain the acidified oil of this embodiment. In this example, 120 kg of sulfuric acid with a mass fraction of 92.8% was used to produce 1 ton of acidified oil.

Embodiment 3

[0021] Heat the soapstock to 90°C, add 30kg of sulfuric acid with a mass fraction of 92.8% to 1 ton of soapstock, and carry out the initial acidification reaction with the acid water in the lower layer obtained after the secondary acidification reaction in Example 2, precipitate and separate the upper layer of oil to obtain the primary acidified oil Heat the primary acidified oil to 90°C, add 22 kg of sulfuric acid with a mass fraction of 92.8% to 1 ton of the primary acidified oil for secondary acidification, precipitate and separate the upper layer of oil to obtain the acidified oil of this embodiment. In this example, 112kg of sulfuric acid with a mass fraction of 92.8% was used to produce 1 ton of acidified oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com