Method for producing fine ceramic by using waste ceramic as main material

A technology of fine ceramics and waste ceramics, applied in the field of ceramics manufacturing, can solve the problems of unstable sintering performance, limited application range, and reduced plasticity of the green body, and achieve the effect of soft color, wide application range, and bright glaze surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

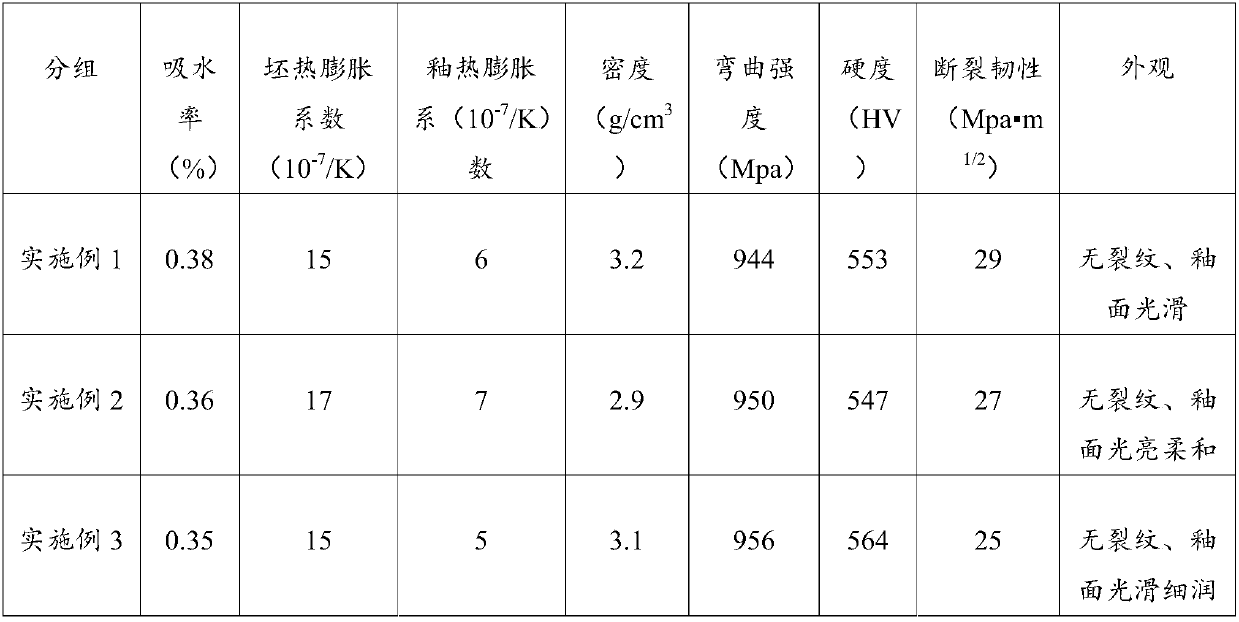

Examples

Embodiment 1

[0022] A method for producing fine ceramics with waste ceramics as the main material, specifically comprising the following steps:

[0023] a. Pulverization: First use a jaw crusher to crush large pieces of waste ceramics into coarse particles, then use a rolling mill to crush the coarse particles of waste ceramics into medium particles, and finally use a jet mill to crush the medium particles of waste ceramics into fine particles. Granules, mixed, passed through a 20-mesh sieve;

[0024] b. Purification: take a hydrochloric acid solution equivalent to 1.0 times the total weight of the waste ceramic fine particles and a concentration of 2.0 mol / L, add the waste ceramic fine particles into the dilute hydrochloric acid solution and soak for 1.0 h;

[0025] c. Adding additives: Based on the weight of waste ceramic powder, add 1% sodium pyrophosphate, a mixture of 2% calcium oxide and magnesium oxide (the mass ratio of calcium oxide and magnesium oxide is 1:1), 1% magnesium sulfat...

Embodiment 2

[0032] A method for producing fine ceramics with waste ceramics as the main material, specifically comprising the following steps:

[0033] a. Pulverization: First use a jaw crusher to crush large pieces of waste ceramics into coarse particles, then use a rolling mill to crush the coarse particles of waste ceramics into medium particles, and finally use a jet mill to crush the medium particles of waste ceramics into fine particles. Granules, mixed, passed through a 20-mesh sieve;

[0034] b. Purification: take a hydrochloric acid solution equivalent to 1.5 times the total weight of the waste ceramic fine particles and a concentration of 2.0 mol / L, add the waste ceramic fine particles into the hydrochloric acid solution and wash for 1.5 hours;

[0035] c. Adding additives: Based on the weight of waste ceramic powder, add a mixture of 3% sodium pyrophosphate, 5% silicon oxide and magnesium oxide (the mass ratio of silicon oxide and magnesium oxide is 1:2), 5% iron sulfate and A...

Embodiment 3

[0042] A method for producing fine ceramics with waste ceramics as the main material, specifically comprising the following steps:

[0043] a. Pulverization: First use a jaw crusher to crush large pieces of waste ceramics into coarse particles, then use a rolling mill to crush the coarse particles of waste ceramics into medium particles, and finally use a jet mill to crush the medium particles of waste ceramics into fine particles. Granules, mixed, passed through a 20-mesh sieve;

[0044] b. Purification: take a hydrochloric acid solution equivalent to 1.5 times the total weight of the waste ceramic fine particles and a concentration of 2.0mol / L, add the waste ceramic fine particles into the hydrochloric acid solution and soak for 1.0h;

[0045] c. Adding additives: Based on the weight of waste ceramic powder, add 2% sodium pyrophosphate, a mixture of 4% magnesium oxide and titanium oxide (the mass ratio of magnesium oxide and titanium oxide is 1:1), 3% iron sulfate and 0.15%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com