Longitudinal cutting mechanism

A longitudinal cutting and main cutting technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor reliability, low cutting precision, and inability to realize rapid and continuous cutting, so as to improve work efficiency, fast slotting and cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

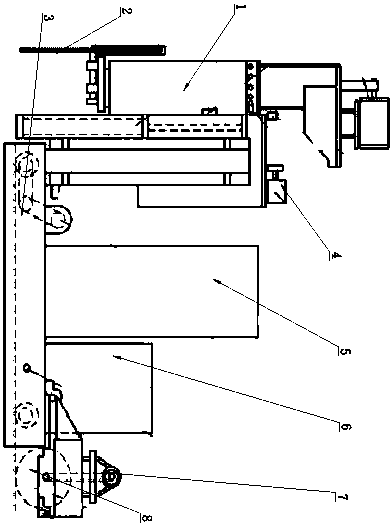

[0013] Such as figure 1 As shown, the purpose of the present invention is achieved in this way: a longitudinal cutting mechanism, including a base 3, the base 3 is arranged horizontally, an electric control cabinet 5 is arranged on the base 3, and the electric control cabinet 5 One side of the base 3 is provided with a hydraulic station 6, the far right side of the base 3 is provided with a slotting machine 8, the slotting machine 8 is driven by the driving device 7, and the slotting machine 8 is equipped with a lifting hydraulic cylinder, so The lifting hydraulic cylinder is directly fixed on the base 3; the left side of the base 3 is provided with a main cutting saw 2, and the main cutting saw 2 is longitudinally connected with a main saw lifting hydraulic cylinder 1, and the upper part of the main saw is matched with a There is a rotary motor 4, the bottom of the rotary motor 4 is directly connected with the main cutting saw 2, the base 3 is also equipped with a locking hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com