Anti-scratch clamping adjustable device in metal circular saw

A clamping device and circular sawing machine technology, applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve problems such as pipe deformation, scratching cutting platform, damage to metal raw materials, etc., to improve service life, cutting The effect of high precision and guaranteed smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

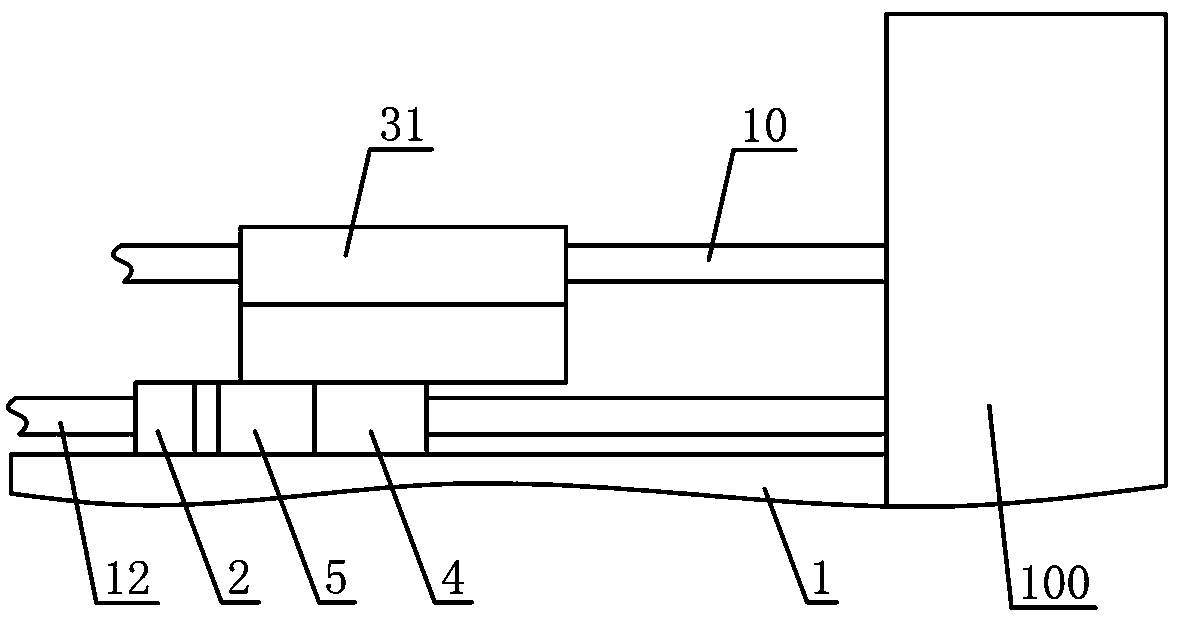

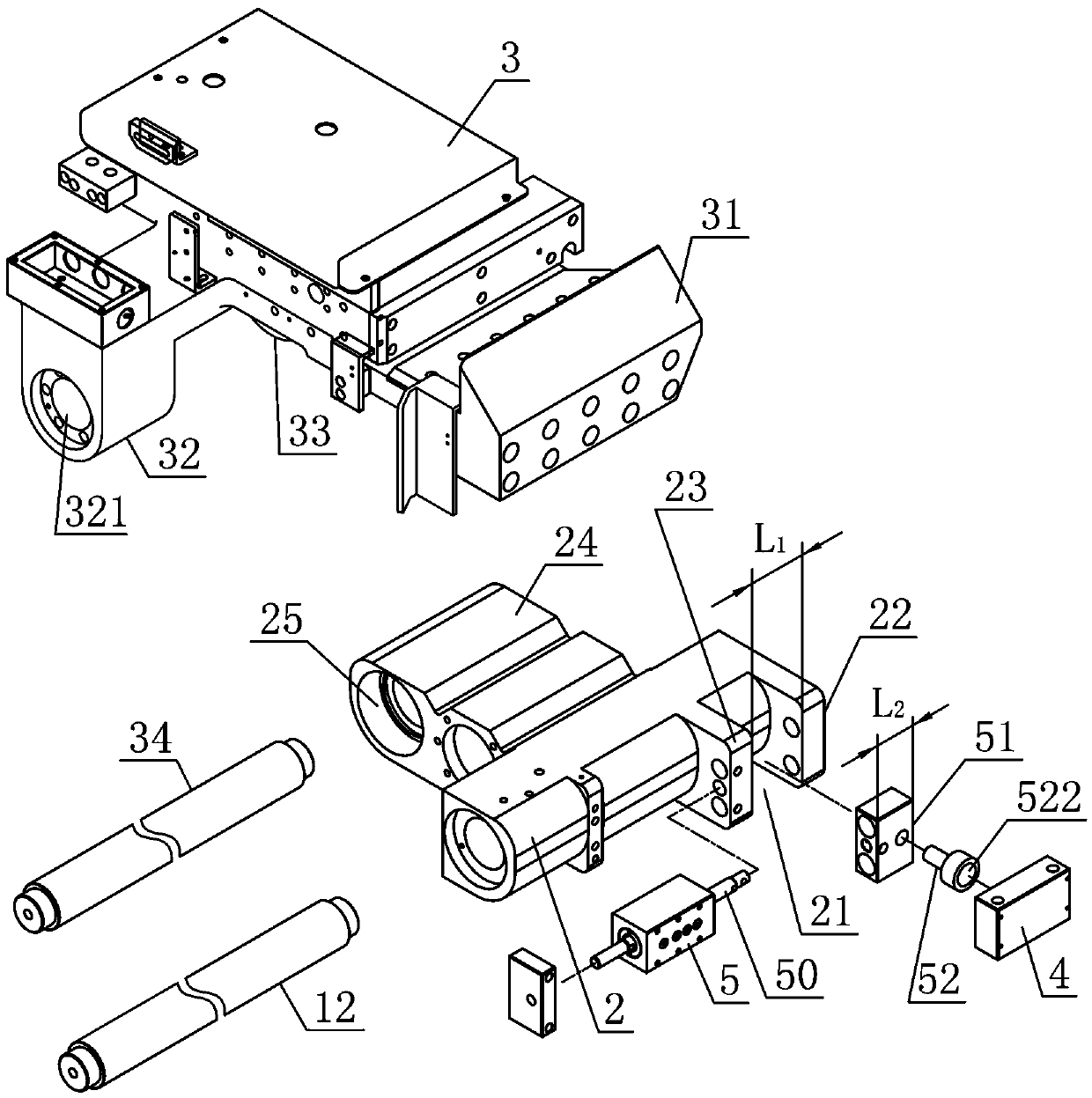

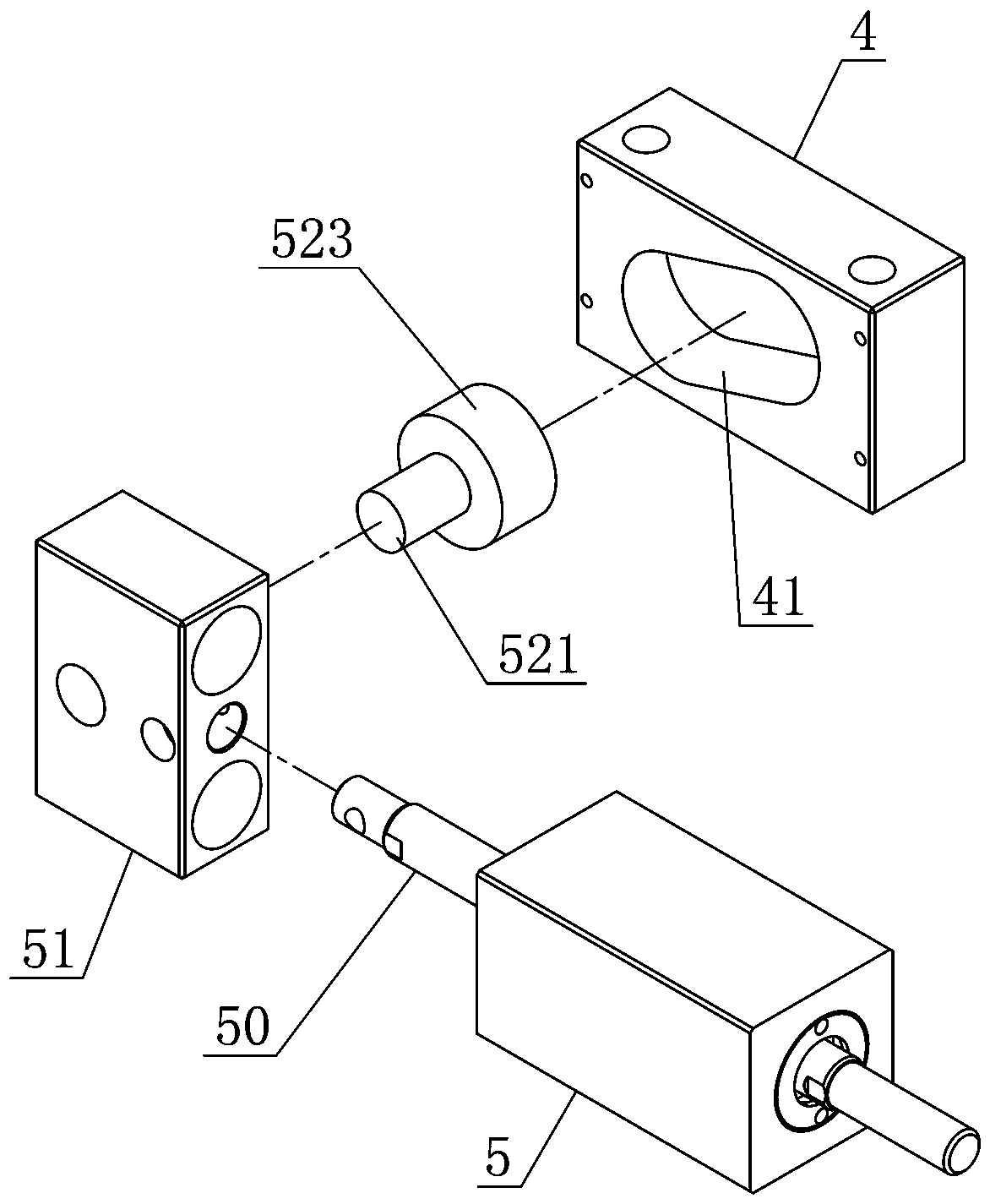

[0028] Such as figure 1 and Figure 4 As shown, the anti-scratch adjustable clamping device in the metal circular saw machine described in this embodiment includes: a frame 1, a cutting platform 11 is horizontally arranged on the frame 1, and the metal raw material 10 is clamped and fixed The clamping device 100 on the cutting platform 11. Such as Figure 6As shown, the clamping device 100 described in this embodiment includes: a horizontal clamp 6, and the structure of the horizontal clamp 6 is: a horizontal clamp seat 62 is provided on the frame 1, and the fixed clamp block 61 is fixedly arranged on the horizontal One side of the clamp seat 62 is provided with a first chute 64 on the horizontal clamp seat 62, and the rear part of the movable clamp block 63 is movably arranged in the first chute 64 of the horizontal clamp seat 62, between the fixed clamp block 61 and the movable clamp block. The top surface of the horizontal clamp seat 62 between the clamping blocks 63 for...

Embodiment 2

[0038] Such as Figure 4 and Figure 6 As shown, the difference between this embodiment and the first embodiment is that the clamping device 100 includes: a horizontal clamp 6 and a vertical clamp 7, and the structure of the horizontal clamp 6 is the same as that of the horizontal clamp in the first embodiment. The structure of 6 is consistent and will not be repeated here. Such as Figure 6 As shown, the structure of the vertical clamp 7 described in this embodiment is: a vertical clamp seat 71 is fixedly arranged on the frame 1, and the rear part of the vertical clamp block 72 is movably arranged on the vertical clamp seat 71. In the second chute 73, the vertical clamping block 72 is driven by the second double-rod cylinder 70 fixedly arranged on the top of the vertical clamp seat 71, and the upper side protruding rod 700 of the second double-rod cylinder 70 is connected with the second The hand wheels 702 are connected with each other, and a second threaded segment is pr...

Embodiment 3

[0046] Such as Figure 7 , Figure 8 and Figure 9 As shown, the difference between the present embodiment and the second embodiment is that a discharge pendulum 8 is hinged on the frame 1 located at the front side of the clamping device 100, and the discharge pendulum 8 can accept the load from the clamping device 100. Falling cutting material. On the frame 1 that is positioned at one side of the discharge pendulum 8, a material distribution cylinder 9 is fixedly arranged, and the extension rod 91 of the material distribution cylinder 9 is connected with the tail of the connecting rod 93 through a universal joint 92, and the material distribution cylinder 9, universal The connection between joint 92 and connecting rod 93 can be realized by threaded connection, such as Figure 9 As shown, the universal joint 92 is movably arranged in the movable hole at the tail end of the connecting rod 93 without falling out of the movable hole. The universal joint 92 is provided with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com