Electrical contact device, electrical connecting unit and method for assembling electrical cable

A technology for contacting devices and connecting units, which is applied to the components of connecting devices, conductive connections, electrical connectors, etc., can solve the problems of discontinuous impedance, limit the maximum usable frequency of plug connectors, etc., and achieve the effect of improving frequency performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

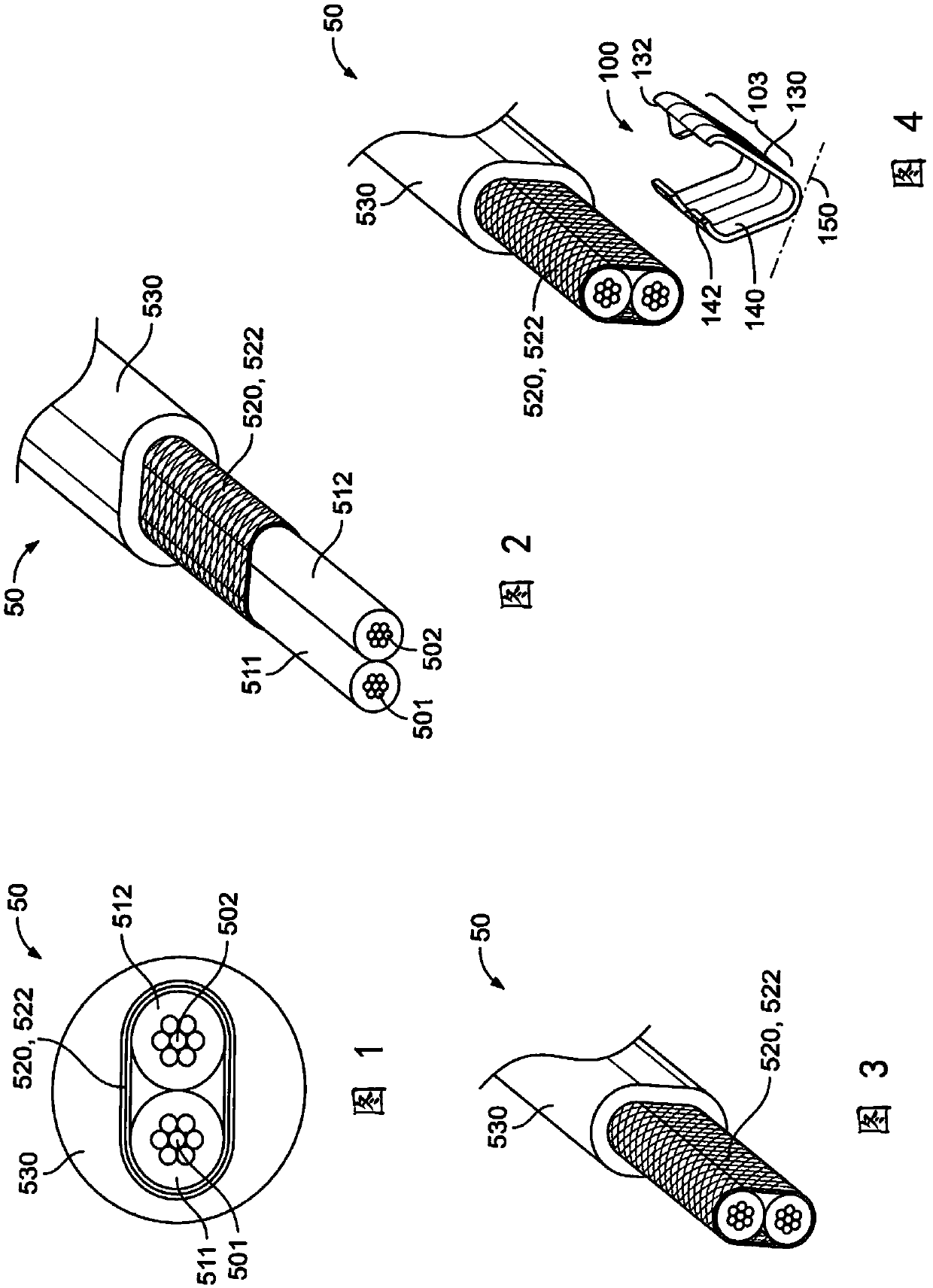

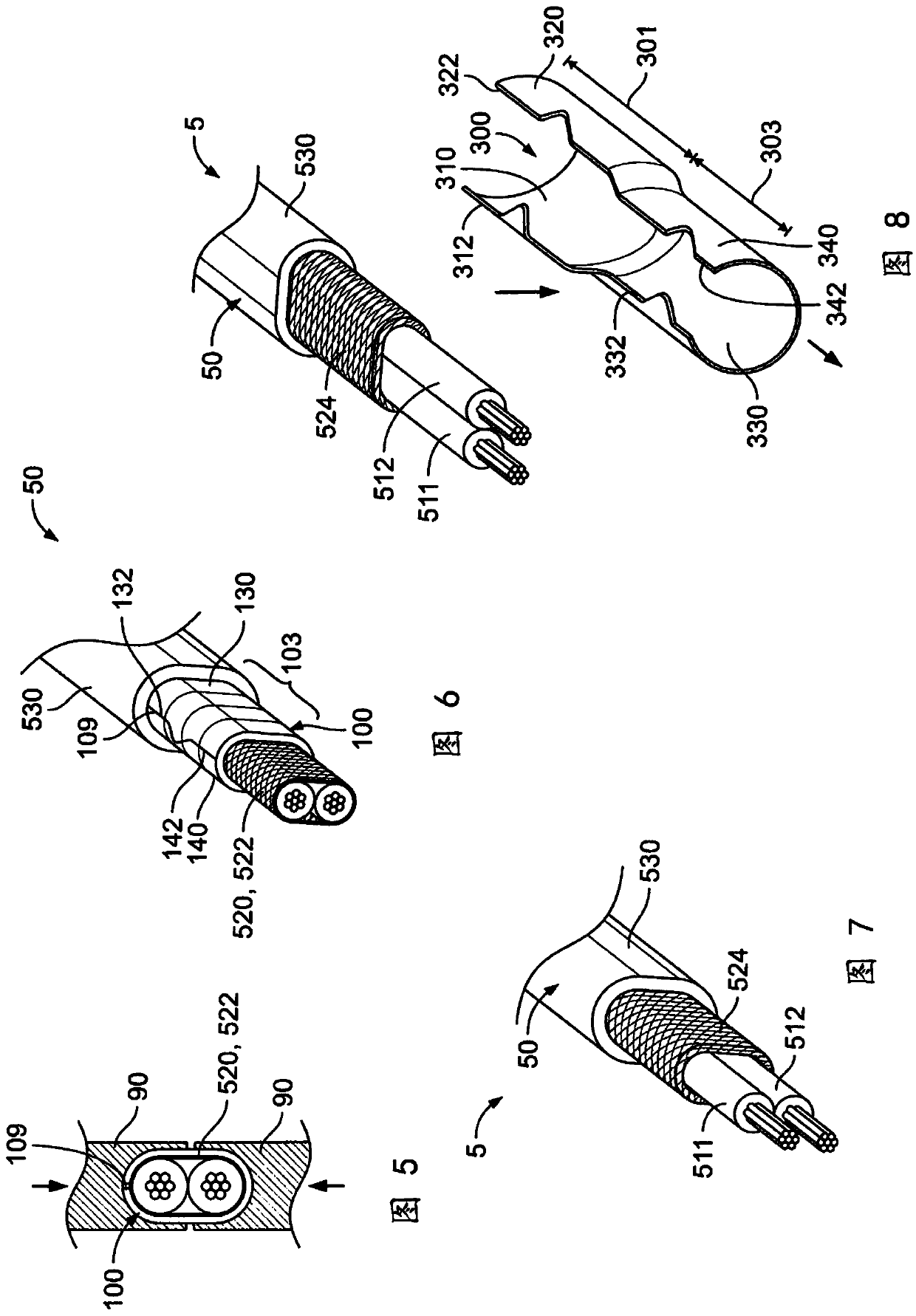

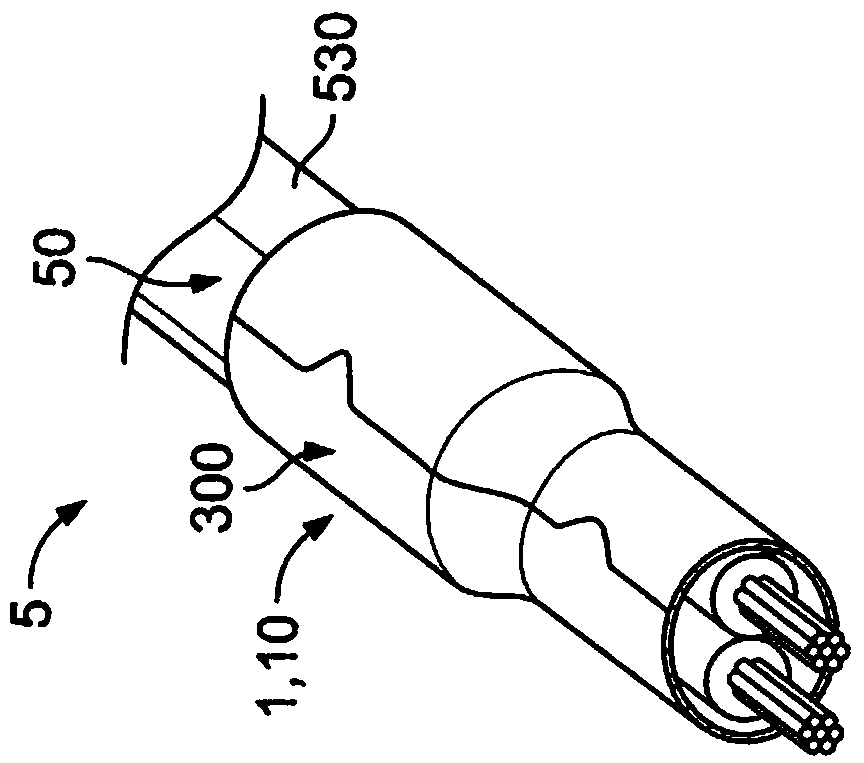

[0046]The invention is explained in more detail below, first in general and then through an exemplary embodiment of a variant embodiment of an electrical biaxial connection unit 10, in particular a miniature biaxial connection unit 10 for the automotive industry, which has four electrical Contact device 100 , 200 , 200 , 300 . In addition, the invention is explained in more detail using an exemplary embodiment of a modified embodiment for the assembly method of the electrical twinaxial cable 50 . Only those spatial parts of the subject matter of the invention which are necessary for understanding the invention are shown in the figures.

[0047] Although the invention has been described and illustrated in more detail and more closely by means of preferred exemplary embodiments, the invention is not limited by the disclosed exemplary embodiments, but is of a more fundamental nature. Other variations can be derived therefrom and / or from the above (description of the invention) w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com