Three-dimensional coupler based on silicon through hole and preparation method thereof

A coupler and through-silicon via technology, which is applied in the field of three-dimensional couplers based on through-silicon vias and its preparation, can solve the problem of small space for directional adjustment, difficulties in integrating discrete three-dimensional microwave couplers, and difficulty in improving isolation, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

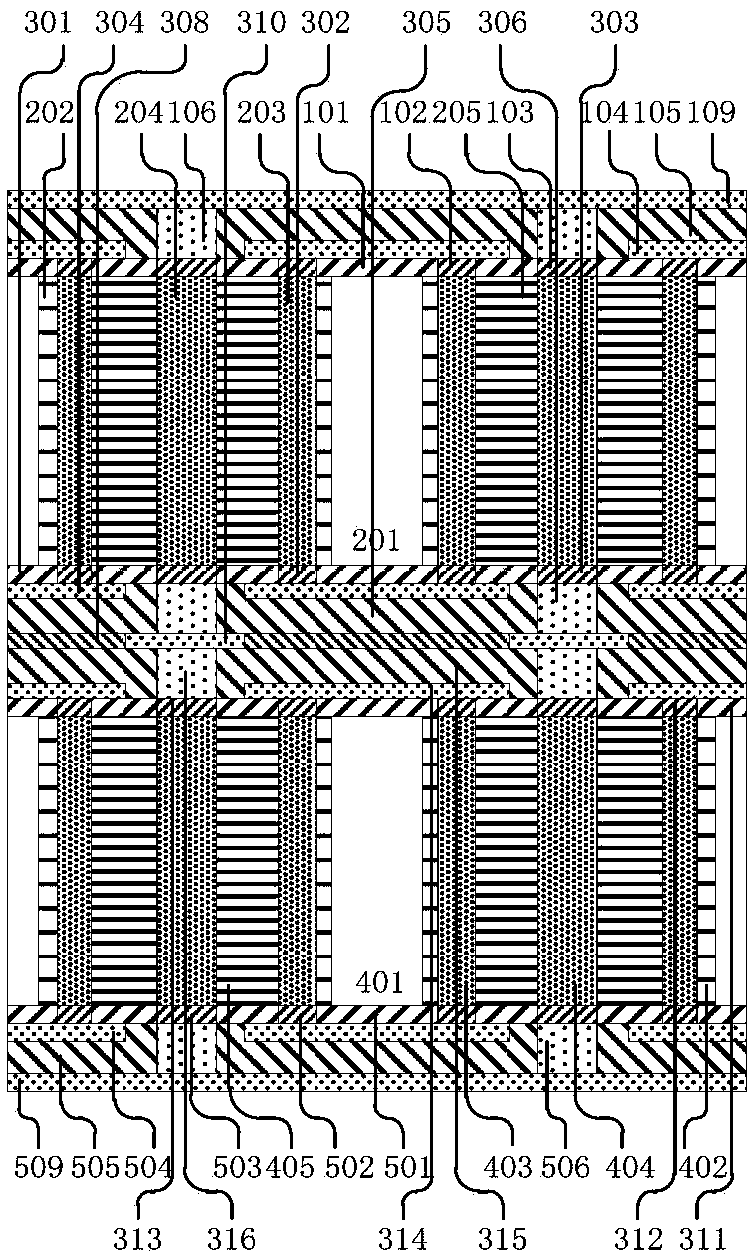

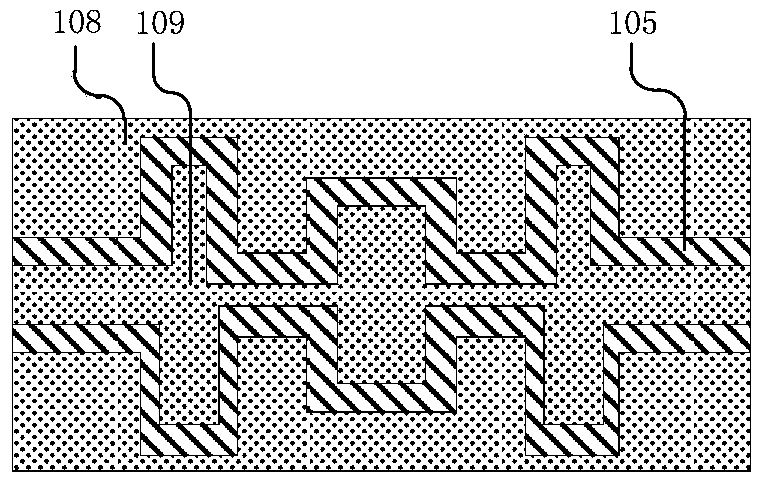

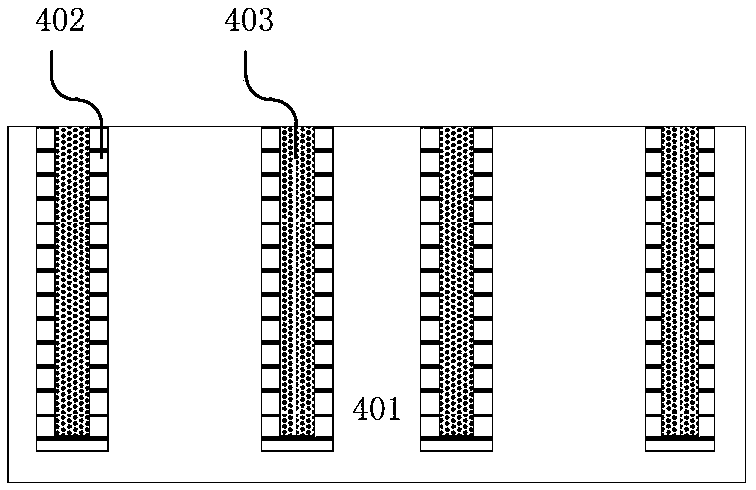

[0122] As shown in Figure 1, a three-dimensional coupler based on through-silicon vias provided by an embodiment of the present invention includes a top ground layer 108, a top signal line 109, a top dielectric layer 105, a top ground column 107, a top signal line Interconnection columns 106, top and bottom ground layers 104, top and bottom dielectric layers 101, top and bottom signal interconnection columns 103, top and bottom shielding layers 102, upper silicon substrate 201, upper first dielectric layer 202, upper shielding layer 203, upper The second dielectric layer 205, the upper signal interconnection column 204, the first dielectric layer 301 at the top of the middle layer, the shielding layer 302 at the top of the middle layer, the first signal interconnection column 303 at the top of the middle layer, the ground layer 304 at the top of the middle layer, and the top of the middle layer The second dielectric layer 305, the second signal interconnection column 306 at the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap