Preparation process of lithium ion oil slurry without glue and oily electrode slurry

A preparation process and lithium ion technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of glue liquid easily adhering to the wall of the pipeline, difficult to clean, and the pipeline is not smooth, so as to improve the production capacity of equipment and equipment. Utilization rate, simplifying process operation steps, improving the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

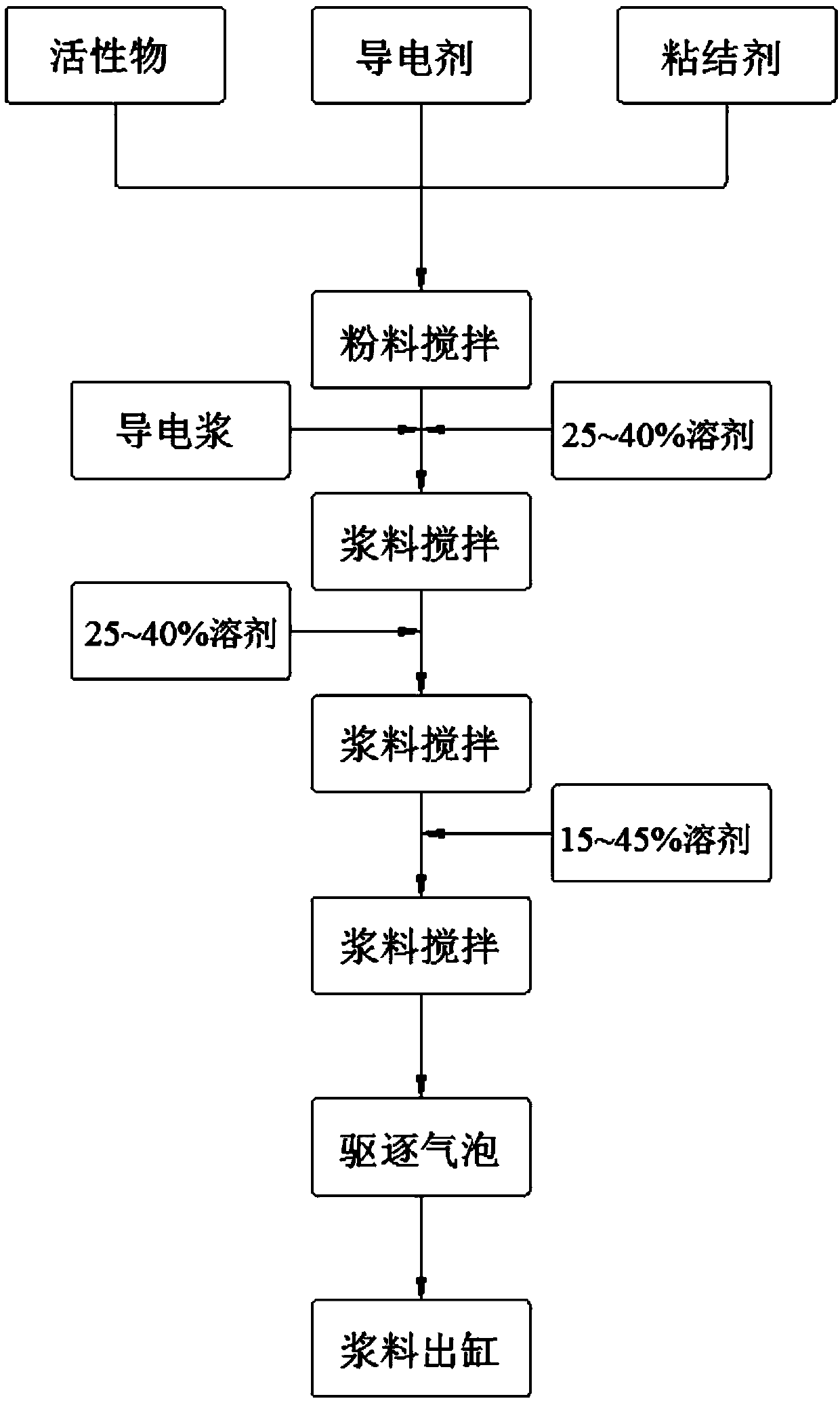

Image

Examples

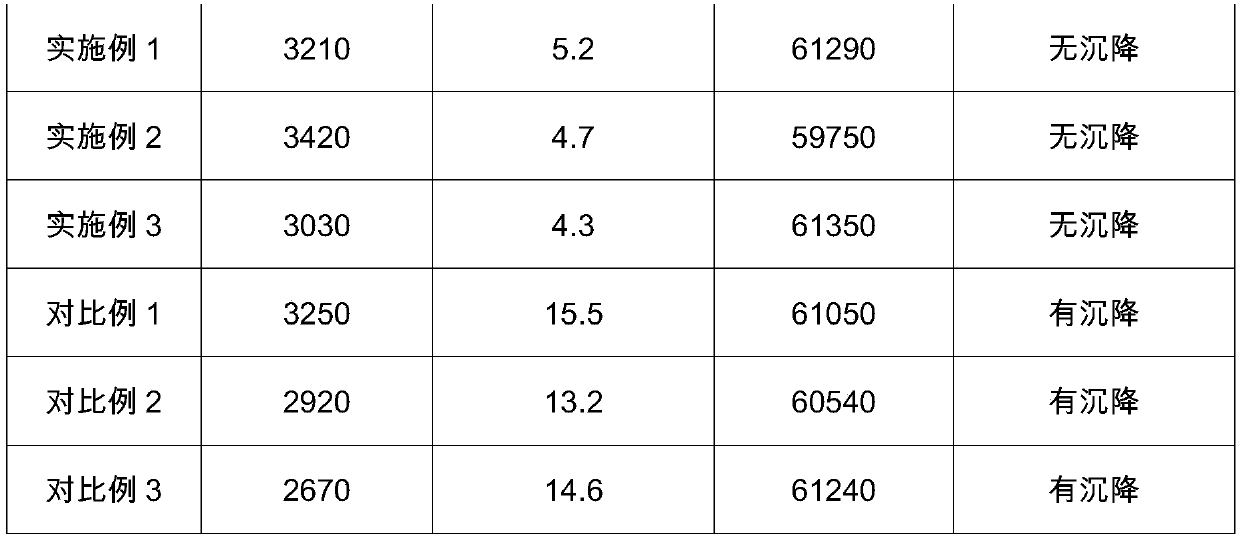

Embodiment 1

[0059] S1, after baking and dehydrating graphite, carbon black, and polytetrafluoroethylene according to the solid content, use a slurry mixer to stir at a revolution speed of 5 RPM and a rotation speed of 25 RPM for 60 minutes to form a mixed powder with a solid content of 90%. ;

[0060] S2, adding tetrahydrofuran and conductive paste with a solid content of 20% to the mixed powder and stirring with a slurry mixer mixer at a revolution speed of 15RPM and an autorotation speed of 25RPM for 60min to obtain a slurry with a solid content of 70% ;

[0061] S3, adding tetrahydrofuran with a solid content of 20% to the slurry of S2, and using a slurry mixing mixer to stir at a revolution speed of 5 RPM and an auto rotation speed of 1500 RPM for 30 minutes;

[0062] S4, add tetrahydrofuran with a solid content of 15% to the S3 slurry, and then use a slurry mixing mixer to stir at a revolution speed of 5 RPM and an auto rotation speed of 1500 RPM for 60 minutes for stirring;

[006...

Embodiment 2

[0067] S1, bake and dehydrate coke, conductive graphite, and polyvinylidene fluoride according to the solid content, and then stir with a slurry mixer mixer at a revolution speed of 15 RPM and an auto rotation speed of 100 RPM for 120 minutes to form a mixed powder with a solid content of 90%. ;

[0068] S2, adding N-methylpyrrolidone and conductive paste with a solid content of 40% to the mixed powder, using a slurry mixer to stir at a revolution speed of 5 RPM and a rotation speed of 100 RPM for 120 minutes to obtain a solid content of 60%. the slurry;

[0069] S3, then add N-methylpyrrolidone with a solid content of 20% to the S2 slurry, and then use a slurry mixer to stir at a revolution speed of 15RPM and an autorotation speed of 1500RPM for 60min;

[0070] S4, add N-methylpyrrolidone with a solid content of 45% to the S3 slurry, and then use a slurry mixing mixer to stir at a revolution speed of 35RPM and an autorotation speed of 3500RPM for 120min for stirring;

[007...

Embodiment 3

[0075] S1, after baking and dehydrating fiber carbon, carbon nanotubes, and polyvinylidene fluoride according to the solid content, use a slurry mixer to stir at a revolution speed of 10 RPM and an auto rotation speed of 50 RPM for 120 minutes to form a mixed powder with a solid content of 85%. ;

[0076] S2, adding N-methylpyrrolidone and conductive paste with a solid content of 30% to the mixed powder, using a slurry mixer to stir at a revolution speed of 10RPM and a rotation speed of 50RPM for 90min to obtain a 65% slurry material;

[0077] S3, adding N-methylpyrrolidone with a solid content of 30% to the S2 slurry, and then stirring at a revolution speed of 10RPM and an autorotation speed of 1500RPM for 60min;

[0078] S4, add N-methylpyrrolidone with a solid content of 45% to the S3 slurry, and then use a slurry mixing mixer to stir at a revolution speed of 20RPM and an autorotation speed of 2500RPM for 90min;

[0079] S5, use the slurry mixing mixer to reversely rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com