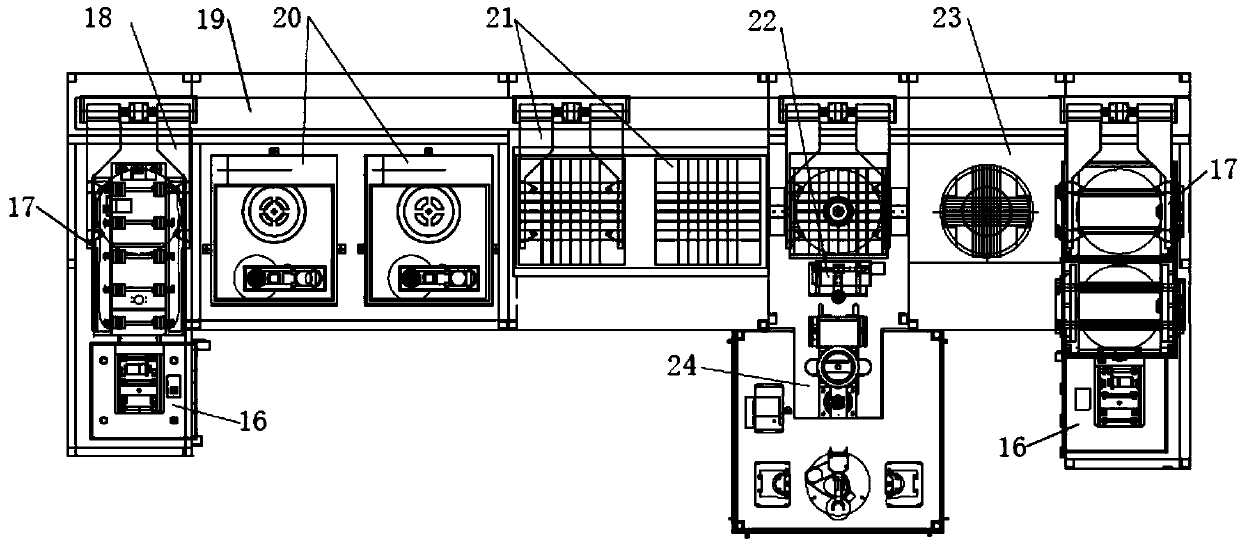

Silicon wafer mounting machine

A technology for placement machines and silicon wafers, which is applied in the manufacture of conveyor objects, electrical components, semiconductor/solid-state devices, etc., can solve the problems of low work efficiency, low production efficiency, slow placement speed, etc. The effect of improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

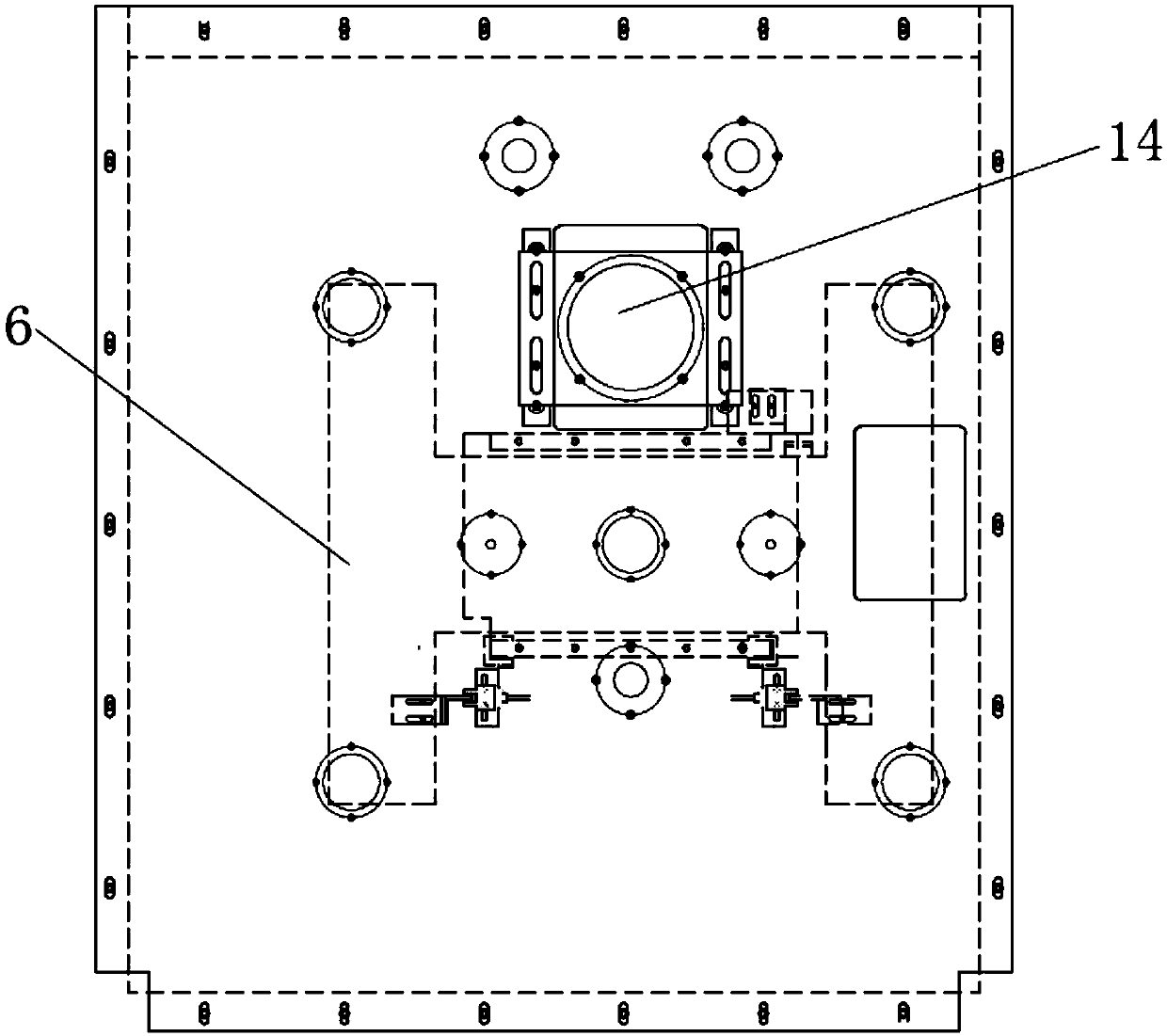

Embodiment

[0058] First push the trolley to the side of the tray inlet and outlet box lifting device 16 on the left side, and several tray inlet and outlet boxes on the cart are pushed into the top plate 2 of the lift frame together, and the left side and the front end of the top plate 2 of the lift frame pass through Baffle plate 15 surrounds, and first driving pulley is installed on the output shaft of the first servomotor 14, and first driving pulley links to each other with driven pulley 3 by belt, and driven pulley 3 drives screw mandrel 12 to rotate, and screw The rotation of the rod 12 drives the bottom plate 11 of the lifting frame and the top plate 2 of the lifting frame through the connecting sleeve 13 to descend. Put them on the first roller 30 one by one from bottom to top, then start the second servo motor 28, and the drive wheel 29 rotates to send the ceramic disc to the transmission mechanism 17. A grating ruler 8 is vertically installed on one side of the vertical plate 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com