Device and method for detecting evolution of corrosion resistance of coating along with deformation of magnesium base material

A corrosion-resistant and coating technology, which is applied in the field of devices for detecting the evolution of coating corrosion resistance as the magnesium substrate deforms, can solve problems such as few research methods, no electrochemical technology, unrealistic requirements, etc., and achieve sample The effect of convenient preparation, flexible operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

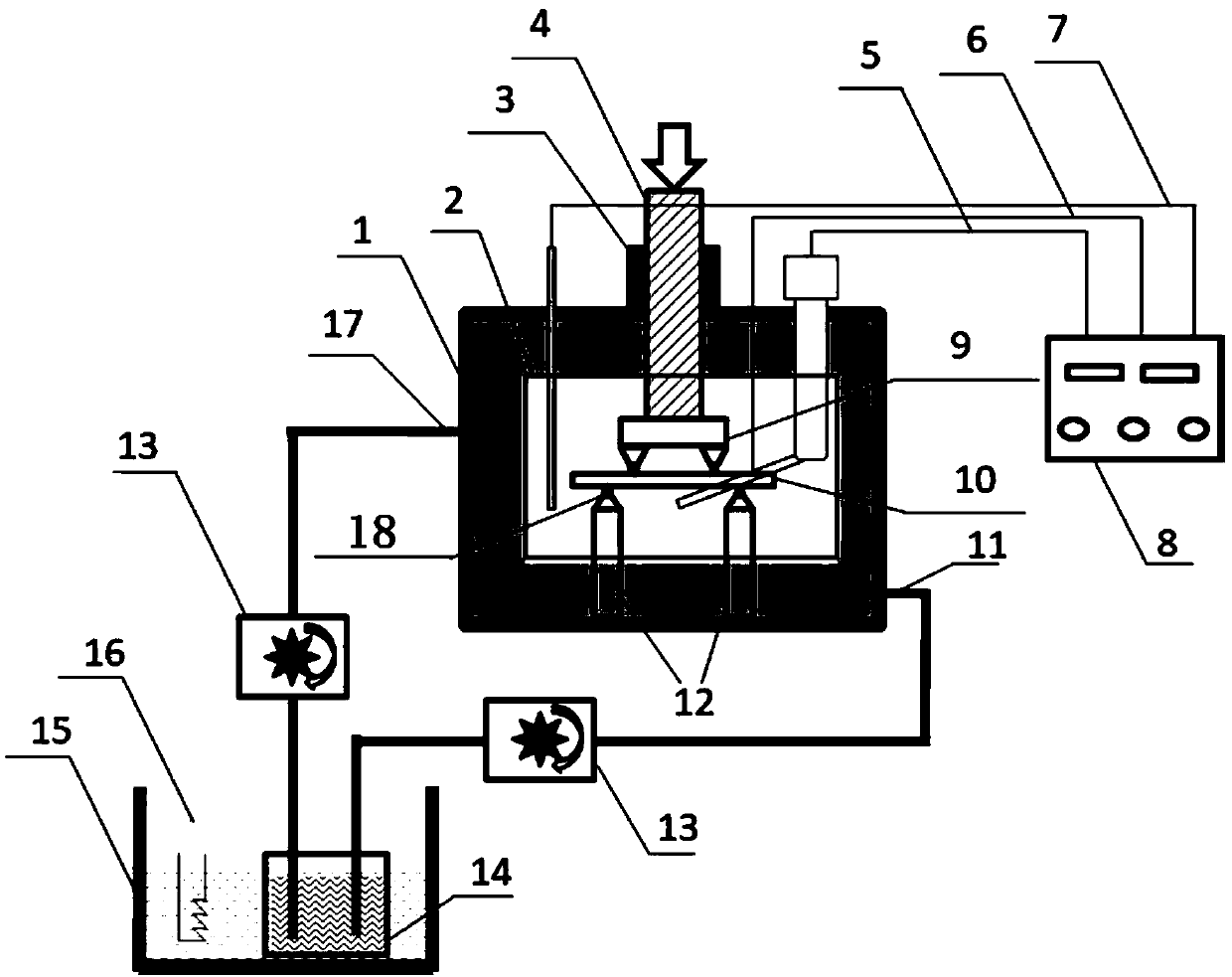

[0032] Such as figure 1 As shown, the embodiment of the present invention provides a device for detecting the evolution of the corrosion resistance of the coating as the magnesium substrate deforms. The device includes a corrosion reaction tank 1 , a sample loading device, a circulation heating device and an electrochemical workstation 8 . The sample loading device is placed in the corrosion reaction tank 1 and connected with the electronic universal testing machine through the connecting rod 4 . The circulation heating device is connected with the corrosion reaction tank 1 through a conduit. The electrochemical workstation 8 is used to detect the electrochemical signal during the bending strain of the sample.

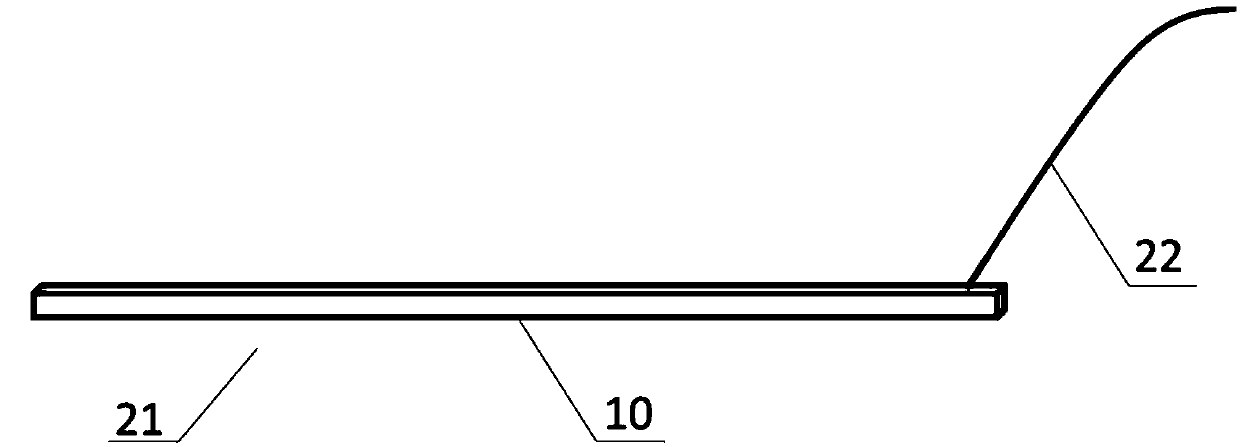

[0033] Such as figure 1 , 2 As shown, the corrosion rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com