Novel micro-through plate and heating radiator and air conditioner tail end equipment provided with same

A through plate and plate technology, applied in the field of heat exchange, can solve the problems of uneven distribution of heat exchange medium, reduce the response speed of heat exchange, and increase the total weight of the radiator, so as to improve the quality and reliability, and improve the heat exchange effect. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

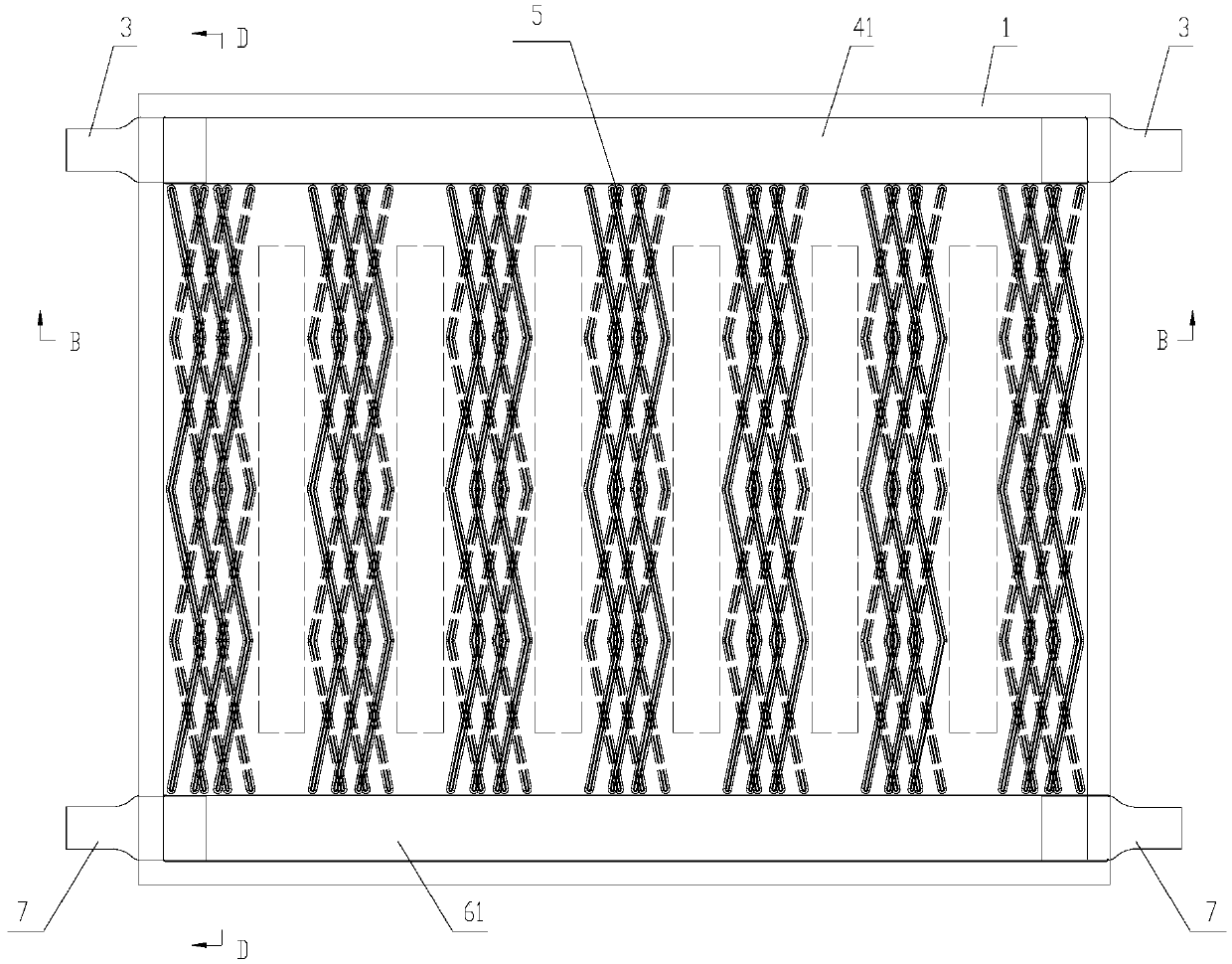

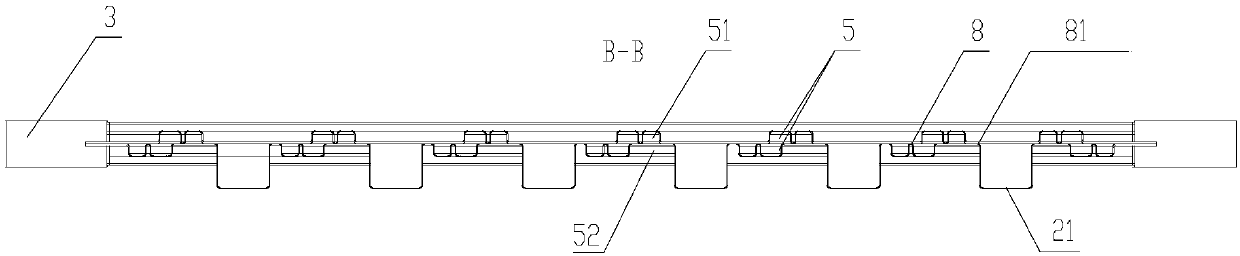

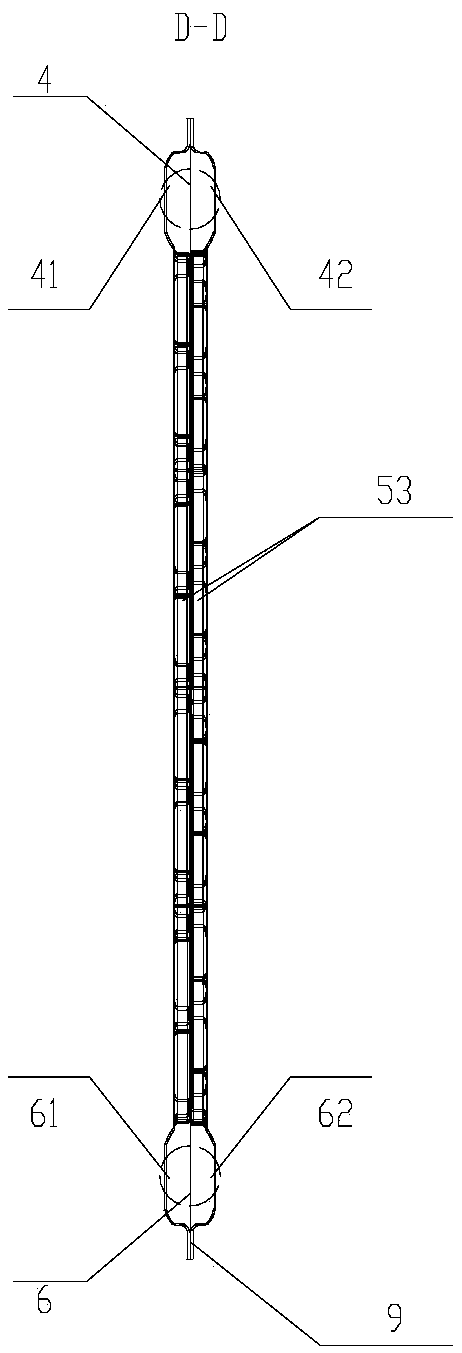

[0041] This embodiment relates to a micro-pass plate, such as Figure 1~5 shown. The micro-pass plate is compositely formed by two plates (the front plate 1 and the rear plate 2 are shown in the figure); specifically, the two plates are closely combined at the joint between the periphery and the middle protrusion. , the connection method mostly adopts the brazing method, and the raised joints 8 on the two plates are composited into a tight fixed point 81 by brazing. The tight fixing points 81 are evenly distributed on the inner side of the plates, and the tight fixing points 81 are mainly used for connection and fixing between two plates, which can ensure the bearing strength of the micro-through plate. In this embodiment, the plates can be processed first, and then the two plates can be combined into a micro-through plate by means of welding or the like. After compounding, except for the medium inlet and outlet, the micro-pass board is sealed all around, and the middle rais...

Embodiment approach

[0046] In the micro-through plate obtained based on the above scheme, at least two of the built-in micro heat exchange channels 5 intersect each other. The fluid medium in the tiny heat exchange channel 5 can generate turbulent flow and turbulent flow. Due to the turbulent flow and turbulent flow generated by the medium, the temperature stratification of the medium is disrupted, and the heat exchange effect is greatly improved. And based on the above principles, various implementation schemes are provided for the improvement of the micro-pass board, as follows:

[0047] (1), in the first scheme, the front plate and the rear plate are provided with corresponding raised joints and tiny medium flow grooves, and the raised joints are used as partitions between the tiny medium flow grooves, which can A dispersal effect is formed on the medium in the micro heat exchange channel 5, and the dispersed medium is distributed into two adjacent micro heat exchange channels, and so on. Dur...

Embodiment 2

[0055] This embodiment also relates to a micro-through plate. The difference between the micro-through plate and the micro-through plate mentioned in Example 1 is that in this solution, the heat-conducting component is externally connected to the heat exchange surface outside the plate. The heat conduction protrusion 21, the heat conduction protrusion 21 and the plates connected thereto form an outer channel for the second medium to pass through; the two ends of the outer channel respectively point to the distribution channel and the collection channel. In this solution, the heat conduction protrusion 21 is circumscribed on the outer heat exchange surface, while the heat conduction protrusion 21 in Embodiment 1 is obtained by integral punching of the plates. Therefore, in this embodiment, the entire tiny heat exchange channel is formed between the two outer heat exchange surfaces, and the heat conducting protrusions 21 can be connected to the plates by means of welding or the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com