Deep groove ball bearing with wave-shaped retainers with oil holes and machining method

A technology for deep groove ball bearings and cages, applied to bearing components, shafts and bearings, bearing cooling, etc., to achieve the effects of reducing noise, increasing lubricity, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

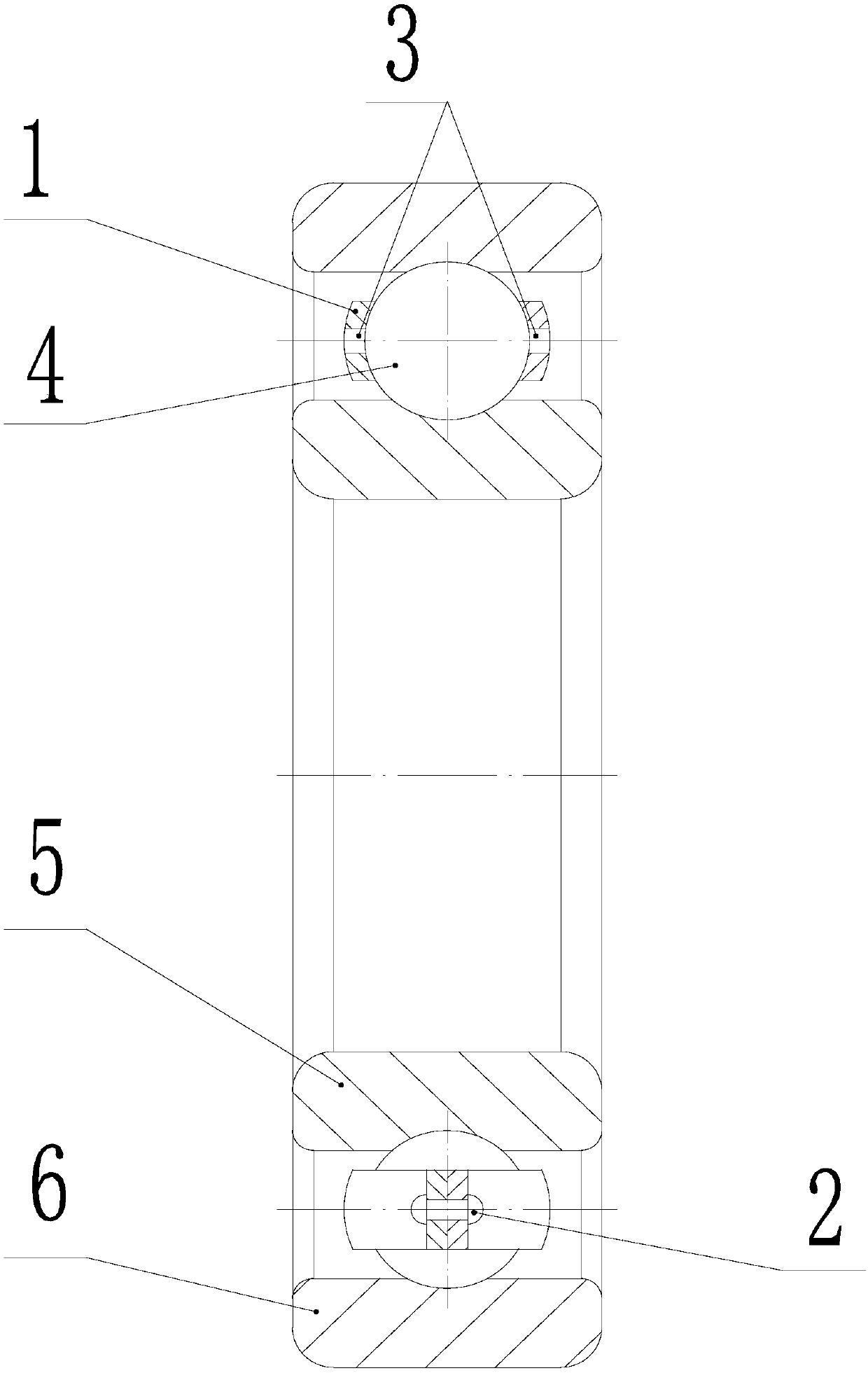

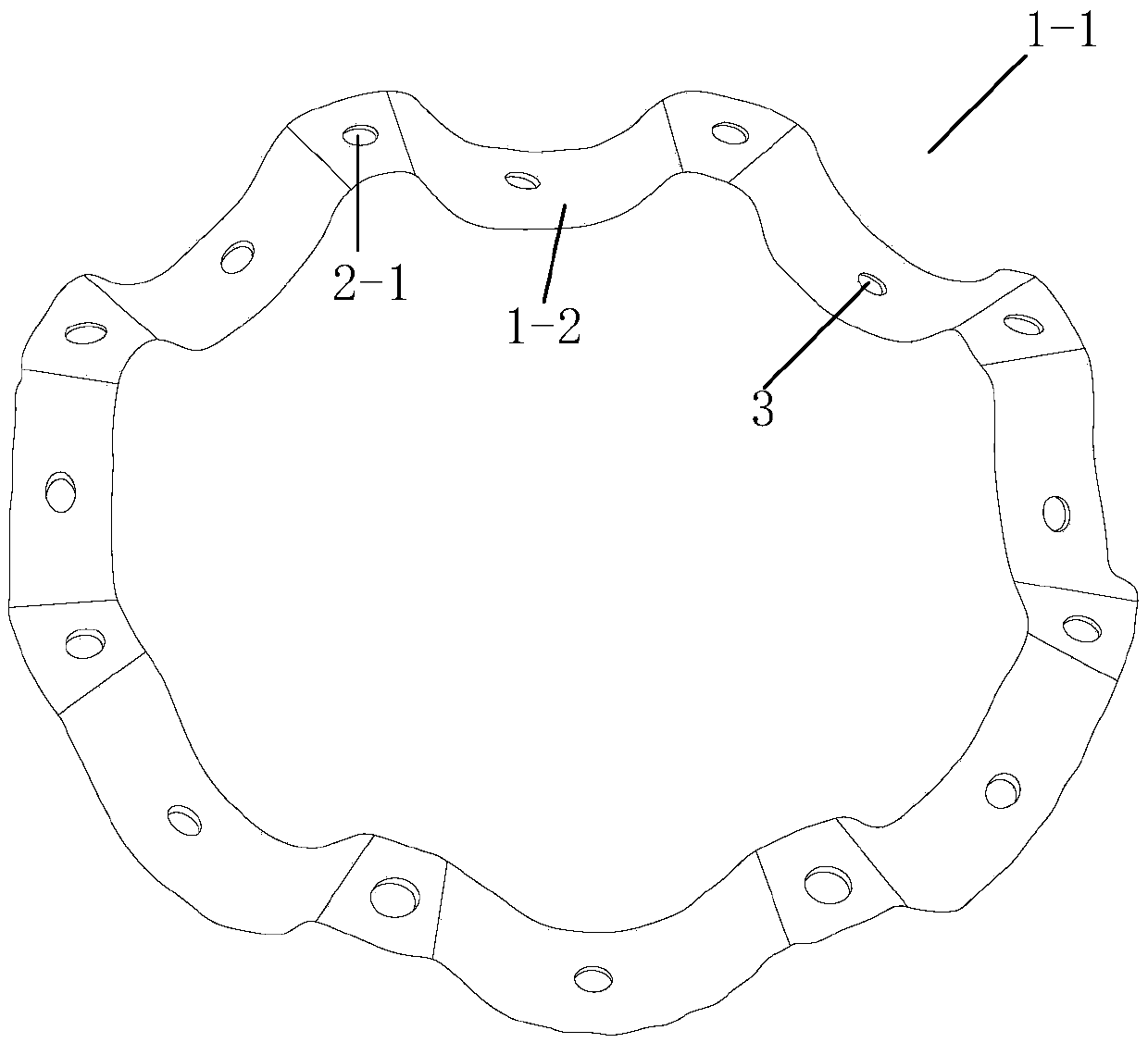

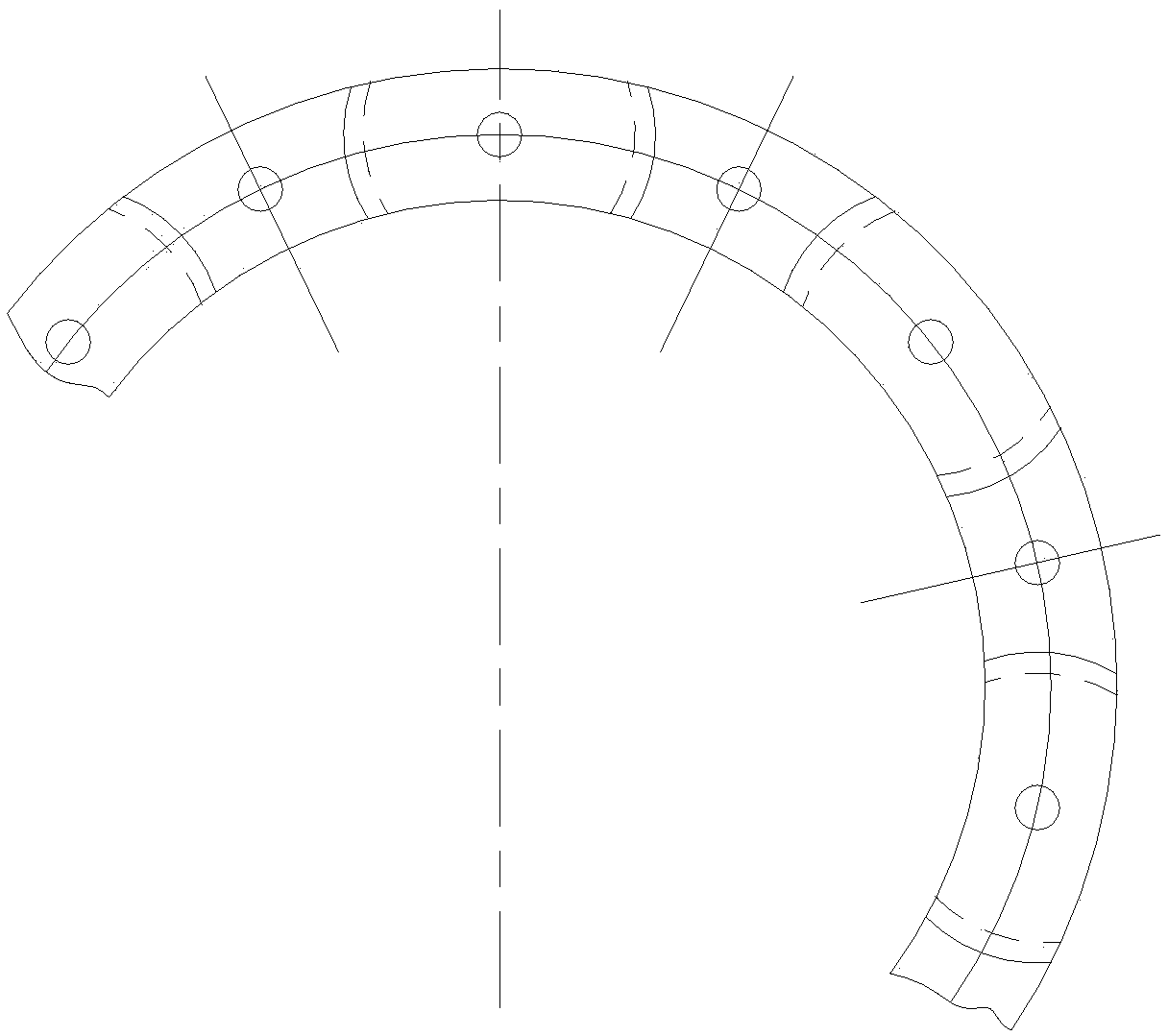

[0014] Specific implementation mode one: refer to figure 1 and Figure 4 Specifically explain this embodiment, the deep groove ball bearing with oil hole wave cage described in this embodiment, the bearing includes wave cage (1), steel ball (4), bearing inner ring (5) and bearing The outer ring (6) and the corrugated cage (1) have a ring structure. The corrugated cage (1) is composed of two corrugated and half cages (1-1), and each corrugated and semi-cage (1- 1) A plurality of pocket holes (1-2) are provided along the circumferential direction, two wave-shaped semi-cages (1-1) are fastened together, and steel balls (4) are arranged on two wave-shaped semi-cages (1-1) 1) in the pocket 1-2;

[0015] A transparent oil hole 3 is opened at the bottom of each pocket 1-2 of each wave-shaped half-cage 1-1.

[0016] In this embodiment, the processing method of the wave-shaped cage of deep groove ball bearings with oil holes does not require additional steps, but the oil holes can b...

specific Embodiment approach 2

[0018] Specific embodiment 2: This embodiment is to further explain the deep groove ball bearing with oil hole wave-shaped cage described in specific embodiment 1. In this embodiment, each piece of wave-shaped half-cage 1-1 is A connecting piece is arranged between the two adjacent pocket holes 1-2, and a rivet hole is opened on the connecting piece, and the rivet 2 is inserted into the rivet hole 2-1 to rivet the two wave-shaped semi-cages 1-1 into an integral structure.

specific Embodiment approach 3

[0019] Specific embodiment 3: This embodiment is to further explain the deep groove ball bearing with oil hole wave-shaped cage described in specific embodiment 1 or 2. In this embodiment, the diameter of the oil hole 3 should not be smaller than the diameter of the rivet hole .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com