Novel supercritical CO2 fracturing process

A new process, supercritical technology, applied in the direction of production fluid, measurement, wellbore/well components, etc., to achieve the effect of economical and effective formation application range, lower requirements, and low difficulty in fracturing construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

[0031] A kind of supercritical CO of the present invention 2 A new process of fracturing, including the following steps:

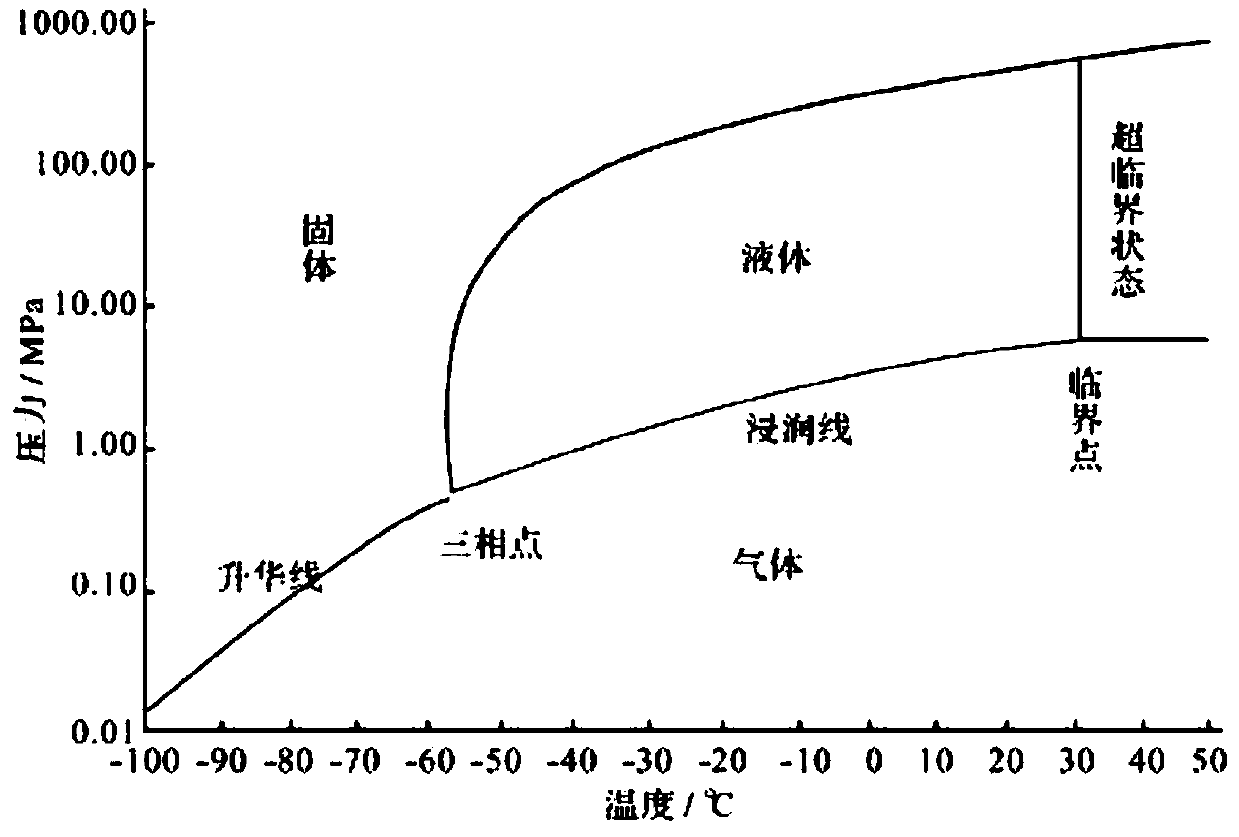

[0032] (1) Critical state CO 2 Preferred fracturing fluid: use CO 2 Tank truck delivery, CO 2 The storage tank is preferably able to withstand a pressure of about 10MPa to ensure that the CO 2 It is in a liquid state at a certain temperature and pressure, and at the same time there must be insulation measures to maintain CO 2 The minimum temperature of the transition state. CO 2 A refrigerator can be installed on the tanker to ensure the needs during transportation and before pumping into the fracturing vehicle. CO 2 Generally, the transportation pressure can be controlled at 3-5MPa, and the temperature can be controlled at -20℃-5℃, so as to ensure the safety of transportation.

[0033] (2) Well cleaning: use clean wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com