A kind of high temperature resistant adhesive tape to prevent roller pressure from overflowing

A technology of high temperature resistance and tape, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of increasing equipment costs, damaging the surface quality of pole pieces, curling, etc., and achieve the effect of preventing folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

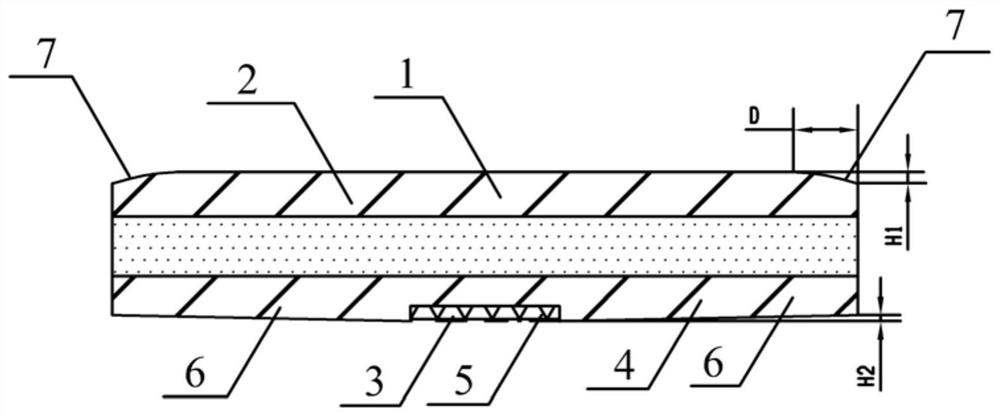

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0023] Such as figure 1 As shown, a high-temperature-resistant adhesive tape for preventing roll overflow of glue of the present invention includes an adhesive tape substrate, and the adhesive tape substrate includes a glass fiber layer 1, an upper Teflon layer 2, a lower Teflon layer 4 and silicon adhesive The adhesive layer 3 is composed of the upper and lower Teflon layer 2 and the lower Teflon layer 4 on the upper and lower sides of the glass fiber layer 1 respectively. dried to produce figure 1 The upper and lower Teflon layers shown; then there is a notch 5 in the middle of the lower Teflon layer 4, which is used for coating silicon adhesive, and is dried to prepare a si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com