Origanum vulgare essential oil-carboxymethyl cellulose degradable active packaging film

A technology of carboxymethyl cellulose and degradable activity, applied in the field of oregano essential oil-carboxymethyl cellulose degradable active packaging film and its preparation, can solve the problem that it cannot be melted into the film, and the essential oil floats on the surface of the film after drying , pollution of nutrients and other issues, to achieve good mechanical properties, improve the effect of inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

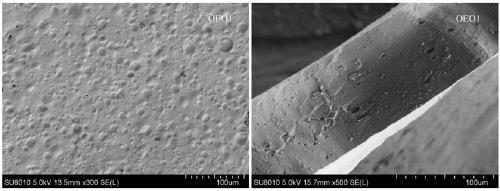

Image

Examples

Embodiment 1

[0035] The oregano essential oil-carboxymethylcellulose active film is prepared by the following preparation method, and the steps are as follows:

[0036] Step (1): Weigh 1 g of carboxymethyl cellulose, add 100 mL of distilled water, and magnetically stir in a water bath at 80°C until completely dissolved; then add 0.5 mL of glycerin as a plasticizer and continue magnetic stirring for 1 hour to form a uniform, transparent membrane liquid;

[0037] Step (2), take 1 mL of oregano essential oil and 0.1 mL of Tween 80, vortex and mix them, add them to 100 mL of membrane liquid, and homogenize at a speed of 13,500 rpm for 4 minutes to obtain a film-forming base liquid;

[0038] Step (3), at 55 ° C, the film-forming base solution is left to defoam, and then pour the defoamed film-forming base solution into a petri dish with a diameter of 15 cm to form a film; transfer it to a blast drying oven , dried at 40°C for 20 h, and peeled off the film to obtain oregano essential oil-carbox...

Embodiment 2

[0040] The oregano essential oil-carboxy cellulose active membrane is prepared by the following preparation method, and the steps are as follows:

[0041] Step (1): Weigh 1 g of carboxymethyl cellulose, add 100 mL of distilled water, and magnetically stir in a water bath at 80°C until completely dissolved; then add 0.5 mL of glycerin as a plasticizer and continue magnetic stirring for 1 hour to form a uniform, transparent membrane liquid;

[0042] Step (2), take 2 mL of oregano essential oil and 0.2 mL of Tween 80, vortex and mix, add to 100 mL of membrane liquid, homogenize at a speed of 13500 rpm for 4 min to obtain a film-forming base liquid;

[0043] Step (3), at 55 ° C, the film-forming base solution is left to defoam, and then pour the defoamed film-forming base solution into a petri dish with a diameter of 15 cm to form a film; transfer it to a blast drying oven , dried at 40°C for 20 hours, and peeled off the film to obtain the oregano essential oil-carboxymethyl cell...

Embodiment 3

[0045] The oregano essential oil-carboxy cellulose active membrane is prepared by the following preparation method, and the steps are as follows:

[0046] Step (1): Weigh 1 g of carboxymethyl cellulose, add 100 mL of distilled water, and magnetically stir in a water bath at 80°C until completely dissolved; then add 0.5 mL of glycerin as a plasticizer and continue magnetic stirring for 1 hour to form a uniform, transparent membrane liquid;

[0047]Step (2), take 3mL oregano essential oil and 0.3mL Tween 80, vortex and mix, add to 100mL film liquid, homogenize at a speed of 13500rpm for 4min to obtain film-forming base liquid;

[0048] Step (3), at 55 ° C, the film-forming base solution is left to defoam, and then pour the defoamed film-forming base solution into a petri dish with a diameter of 15 cm to form a film; transfer it to a blast drying oven , dried at 40°C for 20 h, and peeled off the film to obtain oregano essential oil-carboxymethyl cellulose active film, which is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com