Preparation method of N-carbobenzoxy-3-amino-alanine tert-butyl ester

A technology of tert-butyl alanine and benzyloxycarbonyl, applied in the field of preparation of N-benzyloxycarbonyl-3-amino-alanine tert-butyl ester, can solve the problems of low yield and high cost, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

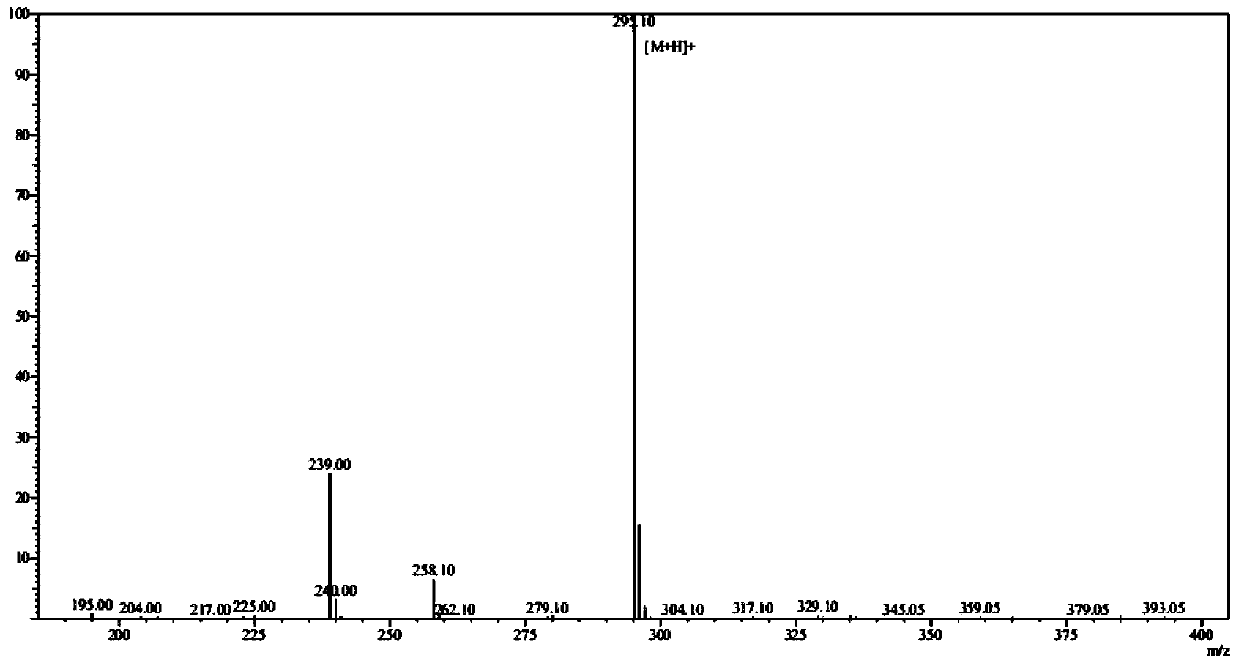

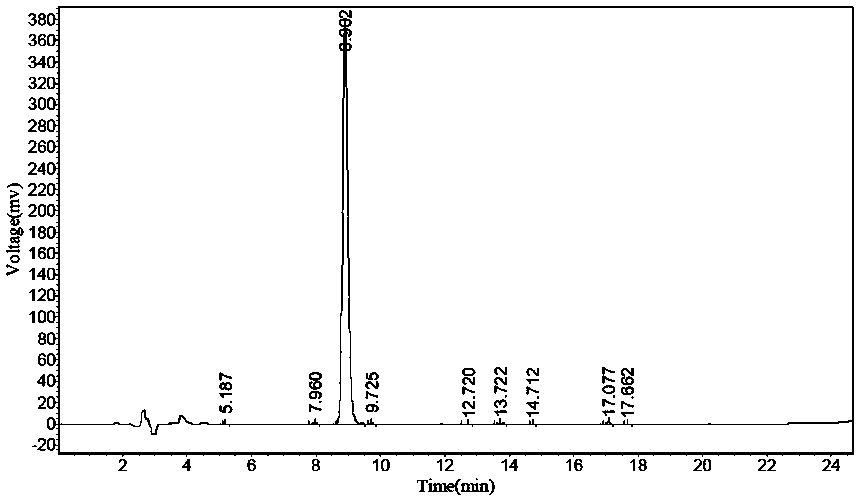

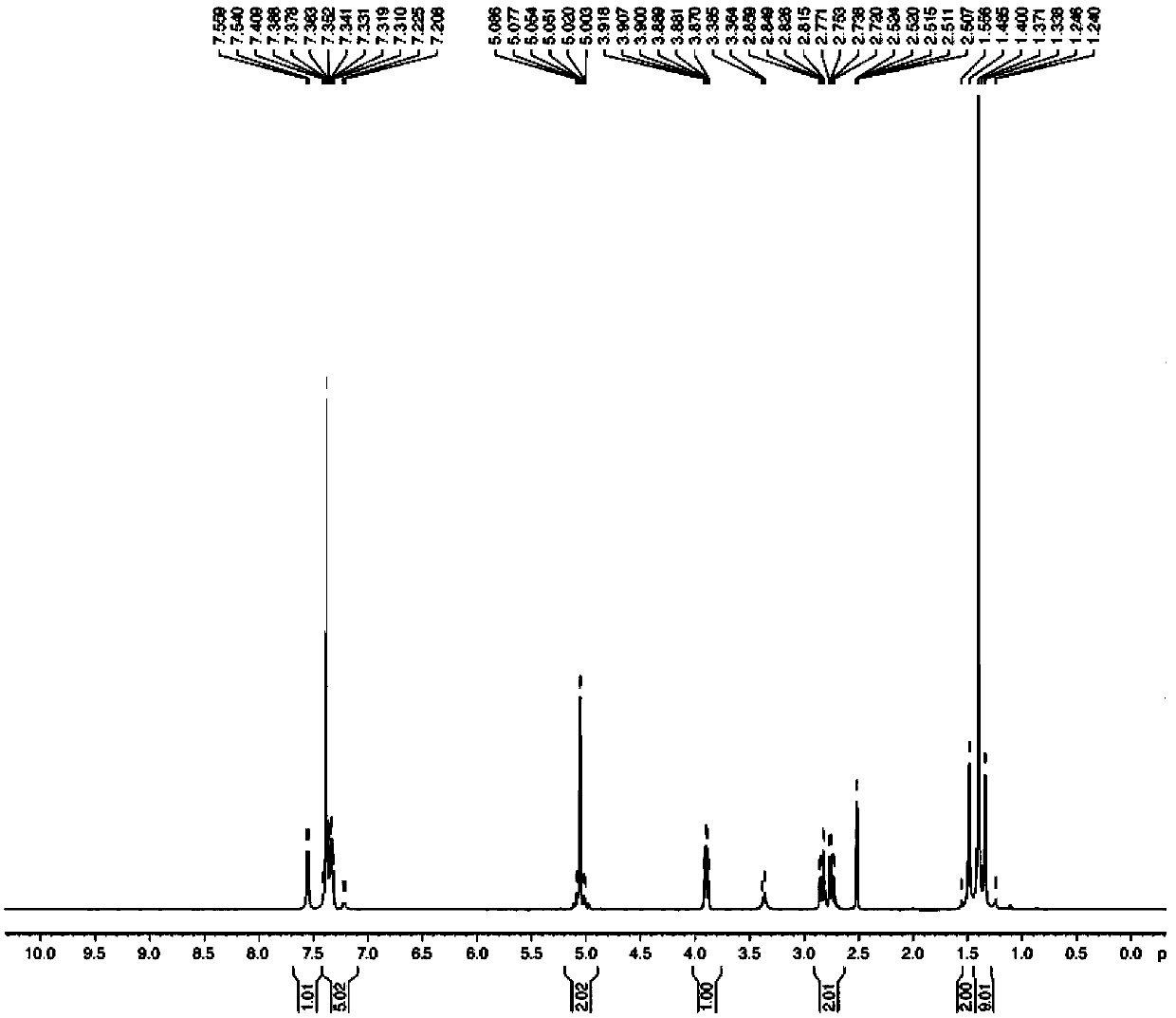

Image

Examples

Embodiment 1

[0022] In the first step, suspend 10KG asparagine in a mixture of 100KG water and 25KG acetone, stir, adjust the pH value between 8-9 with a 20% mass fraction of sodium carbonate solution, cool down to 0°C, and slowly add chlorine Benzyl formate 16KG, keep the temperature below 3°C, add it in 1 hour, then raise the temperature to 18-20°C to react, and react for 10 hours. According to TLC detection, the reaction of the raw materials was completed, acidified with 4 equivalents of hydrochloric acid to pH = 1, and a solid was precipitated, filtered to obtain the intermediate N-benzyloxycarbonylasparagine, and dried to obtain a solid of 18.14KG, with a yield of 90%.

[0023] In the second step, 18.14KG N-benzyloxycarbonylasparagine is suspended in 330KG dichloromethane, stirred, the temperature is lowered to T<-5°C, 33KG of isobutylene is introduced, and 1.81KG of concentrated sulfuric acid with a mass fraction of 98% is added dropwise. Afterwards, the reaction was heated naturally...

Embodiment 2

[0026] In the first step, suspend 100G asparagine in a mixture of 1000G water and 300G acetone, stir, adjust the pH value between 8-9 with a 20% mass fraction of sodium carbonate solution, cool down to 0°C, and slowly add chlorine Benzyl formate 150G, keep the temperature below 3°C, add in 1-2 hours, then raise the temperature to 18-20°C for reaction, and react for 10 hours. According to TLC detection, the reaction of the raw materials was completed, acidified with 4 equivalents of hydrochloric acid to pH = 1, and a solid was precipitated, filtered to obtain the intermediate N-benzyloxycarbonylasparagine, and dried to obtain a solid of 182G, with a yield of 90.3%.

[0027] In the second step, 182G N-benzyloxycarbonyl asparagine is suspended in 2730G dichloromethane, stirred, the temperature is lowered to T<-5°C, 364G of isobutylene is introduced, and 18.2G of concentrated sulfuric acid with a mass fraction of 98% is added dropwise. Natural heating reaction. Sealed and reacted...

Embodiment 3

[0030]In the first step, suspend 2KG asparagine in a mixture of 20KG water and 4KG acetone, stir, adjust the pH value between 8-9 with a 20% mass fraction of sodium carbonate solution, cool down to 0°C, and slowly add chlorine Benzyl formate is 3.6KG, keep the temperature below 3°C, add it in 2 hours, then raise the temperature to 18-20°C to react, and react for 10 hours. According to TLC detection, the reaction of the raw materials was completed, acidified with 4 equivalents of hydrochloric acid to pH = 1, and a solid was precipitated, and the intermediate N-benzyloxycarbonylasparagine was obtained by filtration, and dried to obtain 3.6KG of a solid, with a yield of 89.3%.

[0031] In the second step, 3.6KG of N-benzyloxycarbonyl asparagine is suspended in 72KG of dichloromethane, stirred, the temperature is lowered to T<-5°C, 5.4KG of isobutylene is introduced, and 0.36KG of concentrated sulfuric acid with a mass fraction of 98% is added dropwise. After completion, the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com