High performance reclaimed asphalt pavement cold patch material and preparation method thereof

A kind of recycled asphalt, high-performance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of environmental pollution and recycling of milling waste, and achieve shortened maintenance time, good adhesion, The effect of fast strength forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

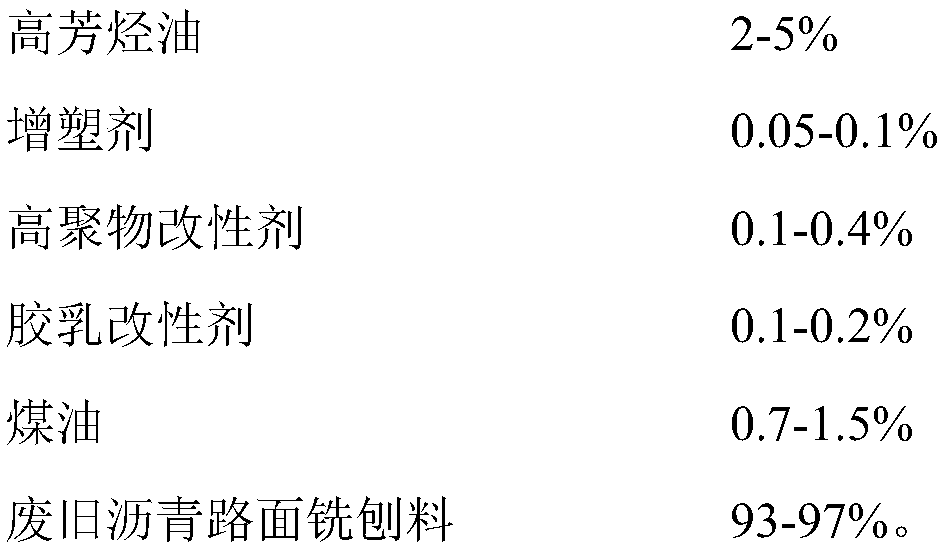

[0037] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0038]

[0039] Product preparation steps:

[0040] (1) earlier 17.15 grams of high aromatic hydrocarbon oil and plasticizer are mixed and stirred to obtain the mixture of high aromatic hydrocarbon oil and plasticizer for stand-by;

[0041] (2) Heat the remaining 17.15 grams of high-aromatic oil to 110°C, then put it into a high-speed shearing device together with the high-polymer modifier and perform cyclic shearing for 15 minutes to obtain high-aromatic oil and high-polymer modifier a mixture of

[0042] (3) Heat the waste asphalt pavement milling material to a temperature of 125°C and pour it into the mixing equipment, add the mixture of high aromatic oil and plasticizer in step (1) at the same time, and stir at a temperature of 125°C for 10 minutes ; Then add the blend of high aromatic oil and high polymer modifi...

Embodiment 2

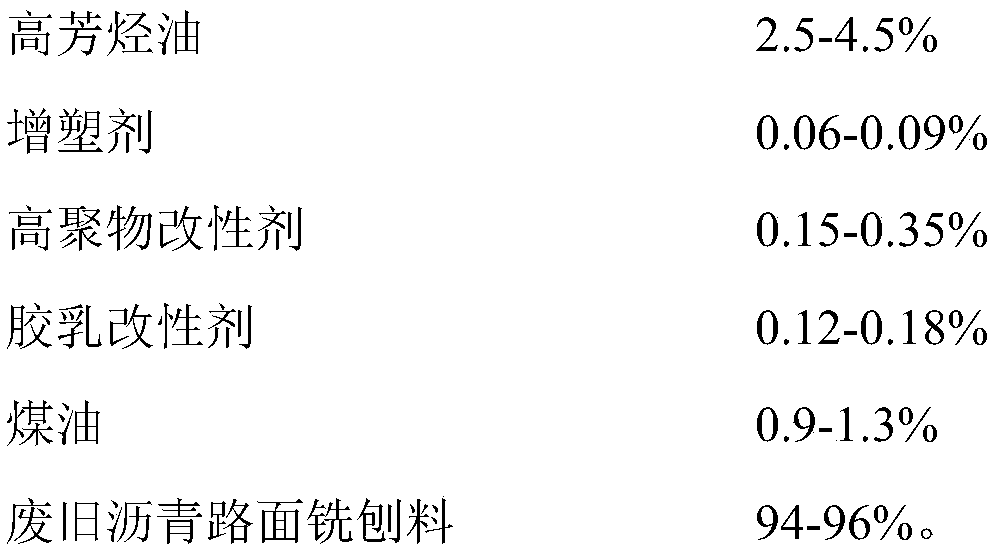

[0045] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0046]

[0047] Product preparation steps:

[0048] (1) 21 grams of high aromatic hydrocarbon oil and plasticizer are mixed and stirred evenly for later use;

[0049] (2) Heat the remaining 21 grams of high-aromatic oil to 115°C, then put it into a high-speed shearing device together with a polymer modifier and perform cyclic shearing for 15 minutes;

[0050] (3) Heat the waste asphalt pavement milling material to a temperature of 120°C and pour it into the mixing equipment, add the mixture of high aromatic oil and plasticizer in step (1) at the same time, and stir for 10 minutes at a temperature of 120°C ; Then add the blend of high aromatic oil and high polymer modifier in step (2), and continue to stir for 25 minutes at a temperature of 145°C;

[0051] (4) Add kerosene and latex modifier to the mixture in step (3)...

Embodiment 3

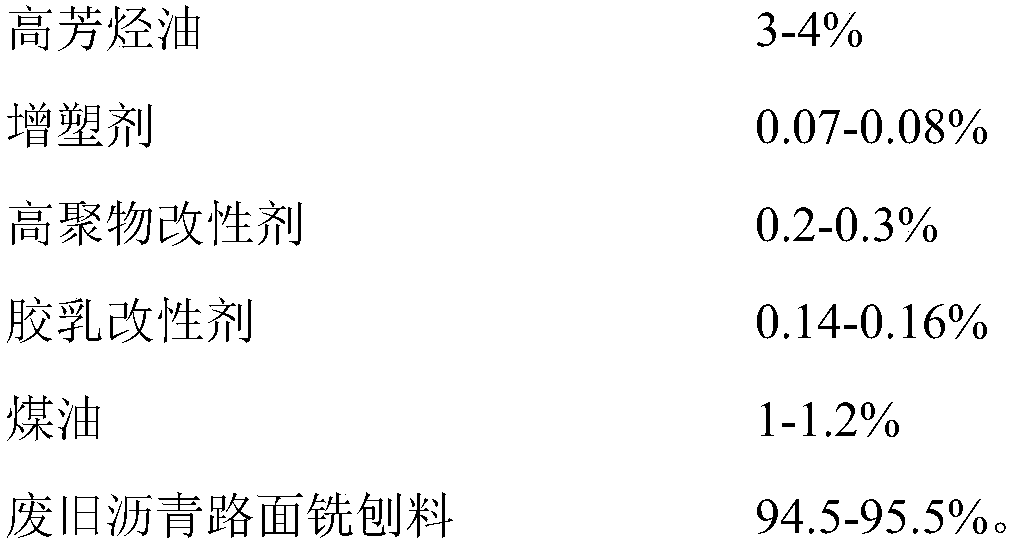

[0053] Taking the production of 1000 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0054]

[0055] Product preparation steps:

[0056] (1) 13 grams of high aromatic hydrocarbon oil and plasticizer are mixed and stirred evenly for later use;

[0057](2) Heat the remaining 13 grams of high-aromatic oil to 110°C, then put it into a high-speed shearing device together with a polymer modifier and perform cyclic shearing for 15 minutes;

[0058] (3) Heat the waste asphalt pavement milling material to a temperature of 130°C and pour it into the mixing equipment, add the mixture of high aromatic oil and plasticizer in step (1) at the same time, and stir at a temperature of 130°C for 15 minutes ; Then add the blend of high aromatic oil and high polymer modifier in step (2), and continue to stir for 20 minutes at a temperature of 140°C;

[0059] (4) Add kerosene and latex modifier to the mixture in step (3),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com