Low linear expansion coefficient epoxy resin based cement concrete road fast repairing material and preparation method thereof

A linear expansion coefficient, cement concrete technology, applied in the field of building materials, can solve the problems of temperature deformation difference, large difference in expansion coefficient, interface damage and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The present invention also provides a preparation method of the low linear expansion coefficient epoxy resin-based cement concrete road rapid repair material described in the above technical solution, comprising the following steps:

[0033] Activated coal gasification slag is obtained by calcining and activating the coal gasification slag;

[0034] Mixing the activated coal gasification slag with a silane coupling agent modification solution to perform a modification reaction to obtain a modified coal gasification slag;

[0035] The medium sand, the modified coal gasification slag and the waste ceramic powder are sequentially added to the epoxy resin slurry and mixed to obtain a low linear expansion coefficient epoxy resin-based cement concrete road quick repair material;

[0036] The epoxy resin slurry includes diluent, curing agent, toughening agent and epoxy resin.

[0037] In the invention, after the coal gasification slag is calcined and activated, activated coal ...

Embodiment 1

[0054] Weigh 100Kg of coal gasification slag and pass it through a 100-mesh square hole sieve, take the sieve with a fineness of less than 100 mesh for drying treatment, and then calcinate and activate it under oxygen-enriched conditions at 600°C for 1 hour to obtain activated coal gasification slag;

[0055] Weigh 2Kg of silane coupling agent Si69 and 98Kg of absolute ethanol, mix and stir evenly at room temperature to prepare a 2wt% silane coupling agent modification solution, then pour 200Kg of activated coal gasification slag into the silane coupling agent modification solution, The weight ratio of silane coupling agent modified solution to activated coal gasification slag is 1:100, vigorously stirred for 30 minutes, and dried at 125°C to obtain modified coal gasification slag;

[0056] Weigh 100Kg of waste ceramic floor tiles for construction and place them in a ball mill for grinding, pass through a 200-mesh square hole sieve, take the under-sieve and place them in a drye...

Embodiment 2

[0064] Weigh 100Kg of coal gasification slag and pass it through a 100-mesh square hole sieve, take the sieve with a fineness of less than 100 mesh for drying treatment, and then calcinate and activate it under oxygen-enriched conditions at 600°C for 1 hour to obtain activated coal gasification slag;

[0065] Weigh 2Kg of silane coupling agent Si69 and 98Kg of absolute ethanol, mix and stir evenly at room temperature to prepare a 2wt% silane coupling agent modification solution, then pour 200Kg of coal gasification slag into the silane coupling agent modification solution, silane The weight ratio of coupling agent modification solution and activated coal gasification slag is 1:100, vigorously stirred for 30 minutes, and dried at 125°C to obtain modified coal gasification slag;

[0066] Weigh 100Kg of waste ceramic floor tiles for construction and place them in a ball mill for grinding, pass through a 200-mesh square hole sieve, take the under-sieve and place them in a dryer for...

PUM

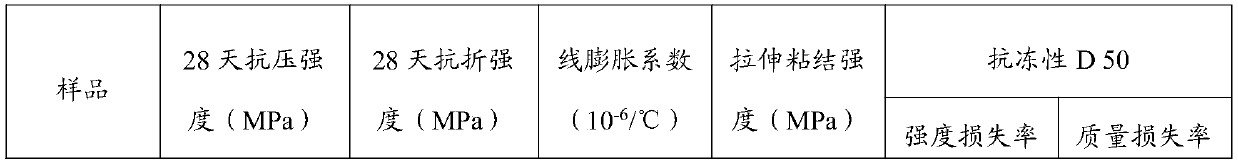

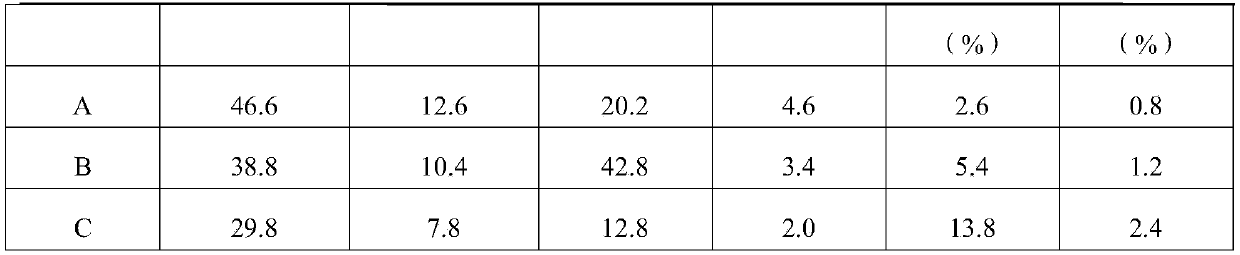

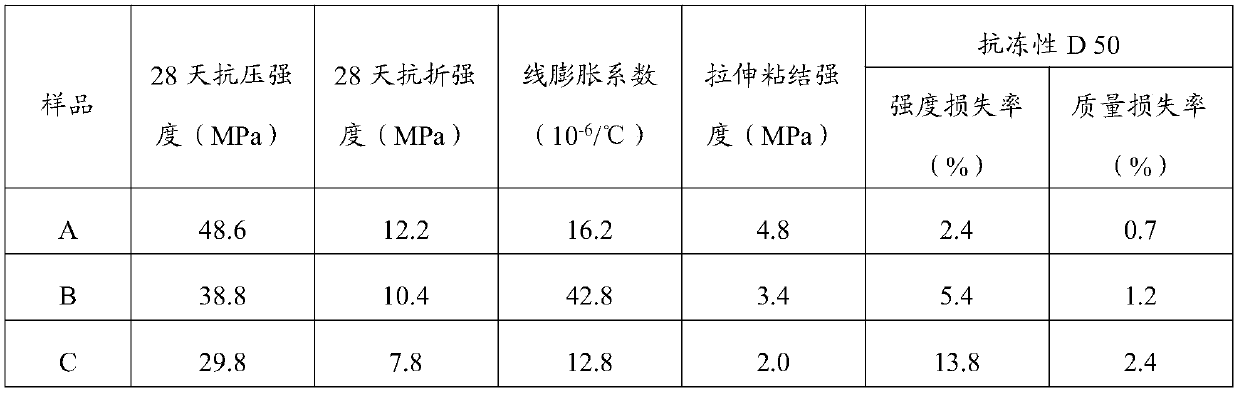

| Property | Measurement | Unit |

|---|---|---|

| Linear expansion coefficient | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com