Device for compactly filling packaging bag with flour materials and compact-filling method

A technology for packing bags and flour, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve the problems of long time, short service life, wear and tear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

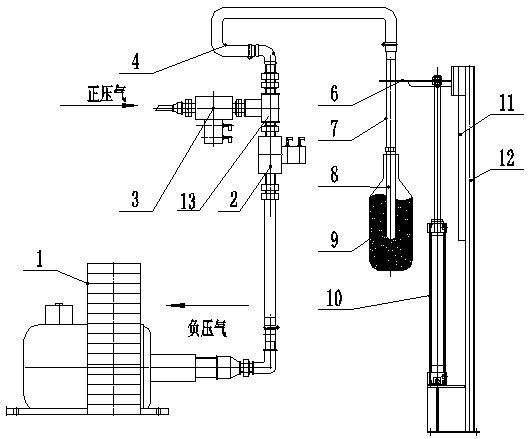

[0014] A kind of flour material filling device in the packaging bag, its composition comprises: guide rail bracket 12, and linear guide rail 11 is installed on the described guide rail bracket, and slide plate 6 is installed on the described linear guide rail, and described slide plate is respectively connected with The cylinder 10 and the steel pipe 7 are connected, one end of the steel pipe is connected with the flexible pipe 4, the other end of the steel pipe is connected with the titanium filter rod 8, the titanium filter rod is inserted into the flour packaging bag 6, and the flexible pipe is connected with the Said shut-off valve one 2 and shut-off valve two 3 are connected, and said shut-off valve two is connected with vacuum blower 1.

Embodiment 2

[0016] According to the device for filling the flour material in the packaging bag described in Example 1, the titanium filter rod is a titanium filter rod with a filtering precision of 30um.

Embodiment 3

[0018] A filling method using the flour material filling device described in any one of claims 1-2, the positive pressure air drives the cylinder to expand and contract, drives the slide plate to move on the linear guide rail, the vacuum fan generates negative pressure, and the valve is closed by closing the stop valve 2. Open the stop valve 1, insert the titanium filter rod with a filtration accuracy of 30um installed on the sliding plate into the flour packaging bag, and the negative pressure will discharge the air in the flour, and the volume of the flour will be reduced, so as to realize the purpose of filling the flour in the packaging bag;

[0019] After each air extraction, the fan stops, the positive pressure air passes through the stop valve 2, closes the stop valve 1, and the positive pressure air enters the hose, steel pipe, filter rod, and the agglomerated flour adsorbed on the filter rod is separated from the filter rod. The whole working process Finish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com