Closed type compressor

A compressor and hermetic technology, applied in the field of compressors, can solve the problems of accelerated loss of lubricating oil, reduction of compressor refrigeration capacity, increase of lubricating oil discharge, etc., to achieve the effect of saving consumption, reducing product cost and improving refrigeration capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, the hermetic compressor of the present invention will be described in detail with reference to the accompanying drawings and embodiments:

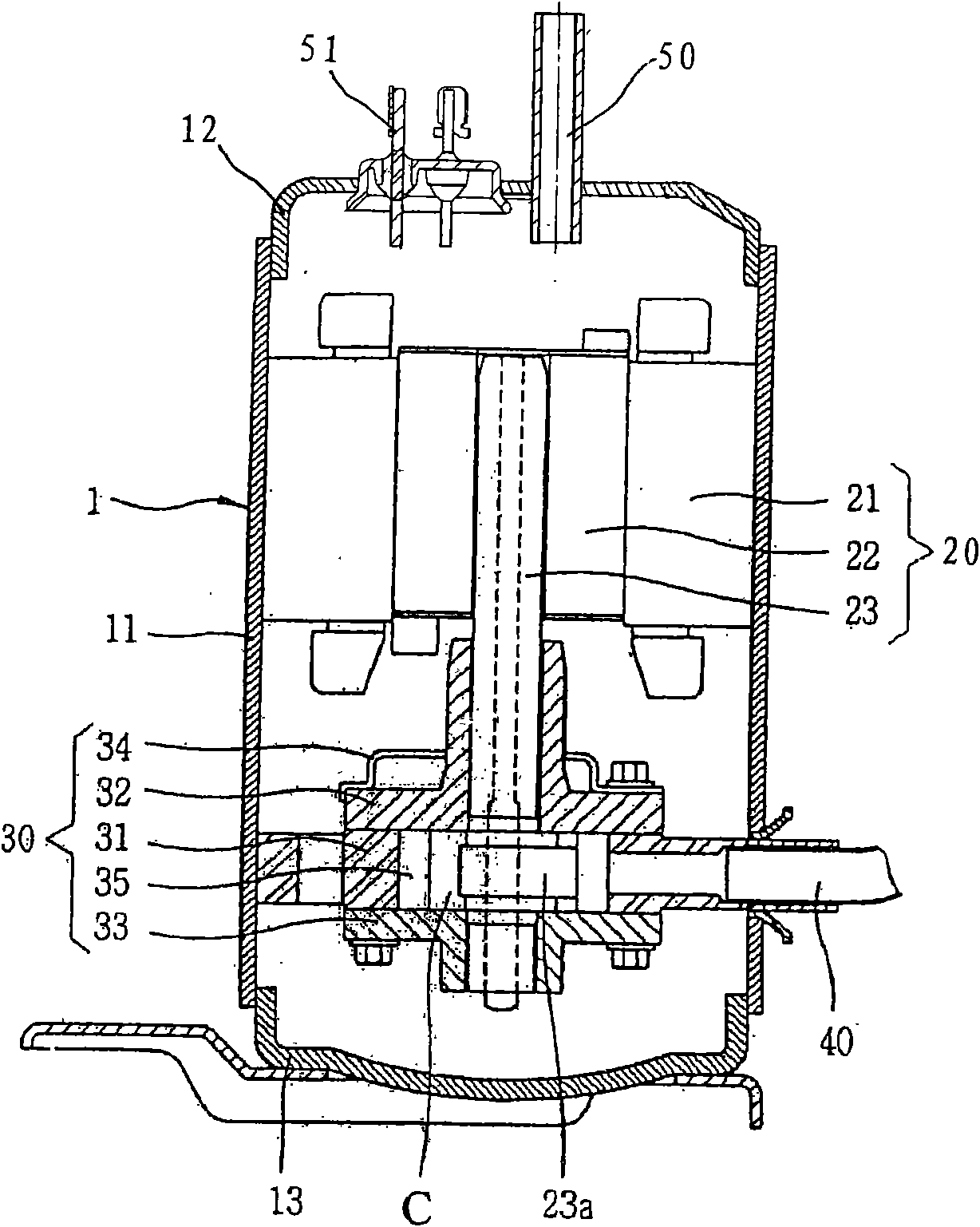

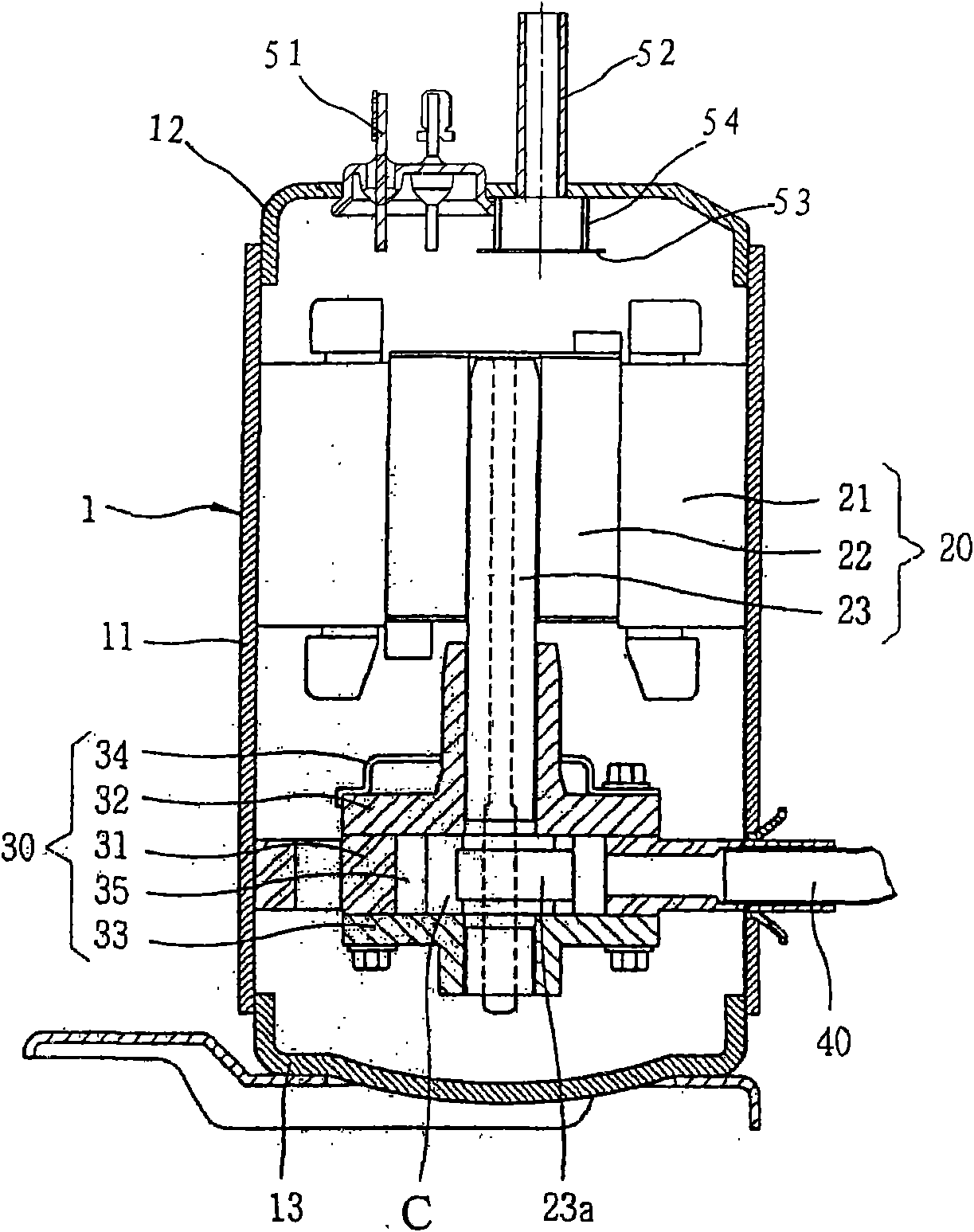

[0025] Such as figure 2 As shown, the hermetic compressor of the present invention includes a housing 1, a motor 20 is installed on the inner upper side of the housing 1, and a compressor assembly 30 is installed on the lower side of the motor 20 at a certain distance. The casing 1 is composed of a hollow cylindrical body 11 , an upper cover 12 , a lower cover 13 and the like. The motor 20 is press-fitted and fixed on the inner peripheral surface of the cylinder 11, and it is composed of a stator 21, a rotor 22, and a rotating crankshaft 23 that is press-fitted and fixed at the center of the rotor 22 and transmits rotational force.

[0026] The compressor assembly 30 includes a cylinder 31, an upper bearing 32 and a lower bearing 33. The eccentric part 23a of the rotating crankshaft 23 is formed inside the compression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com