Washing-free dust removing device

A dust removal device, technology that does not need to be disassembled and cleaned, applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of reduced work efficiency and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

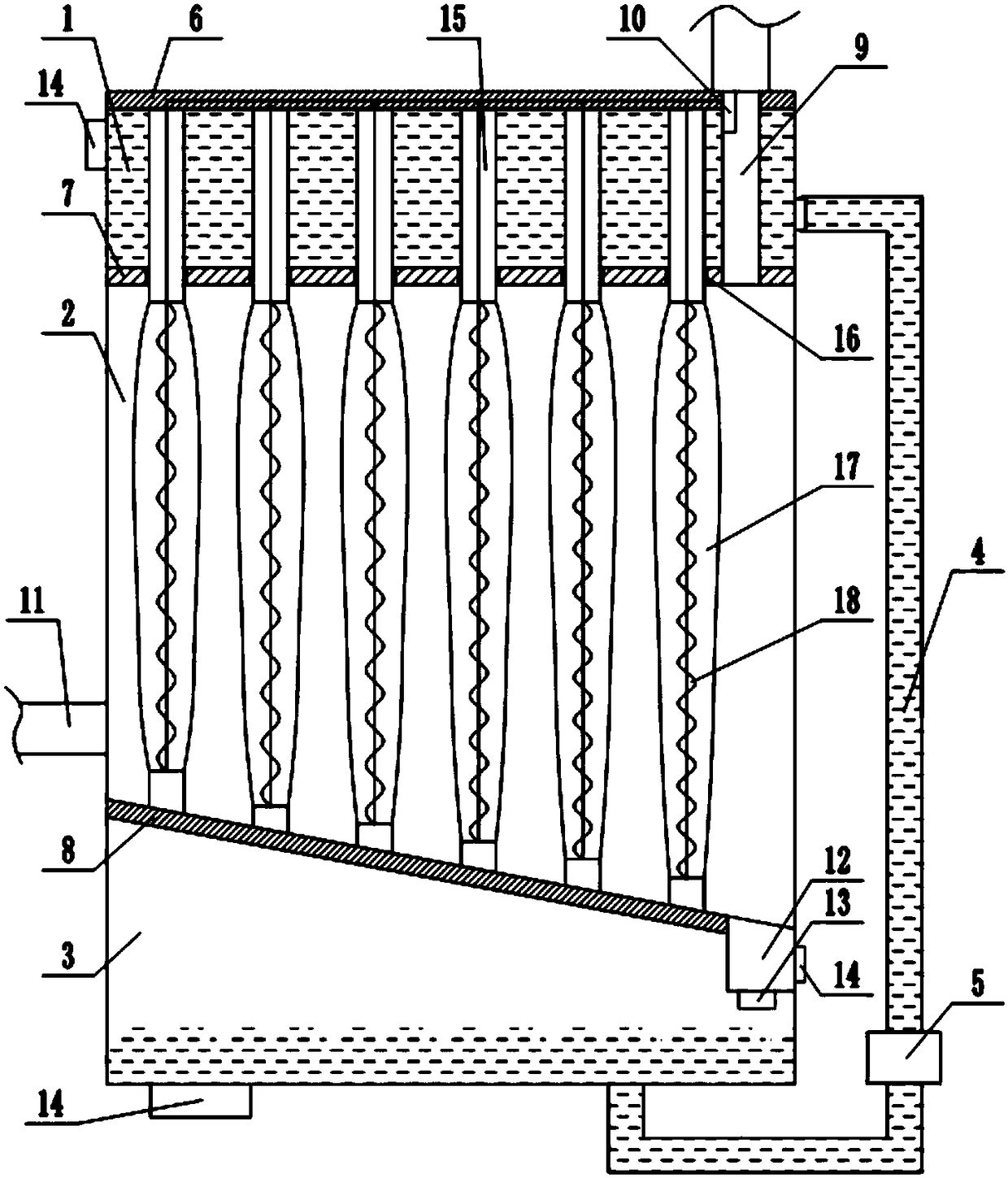

[0021] The following is further described in detail through specific implementation methods:

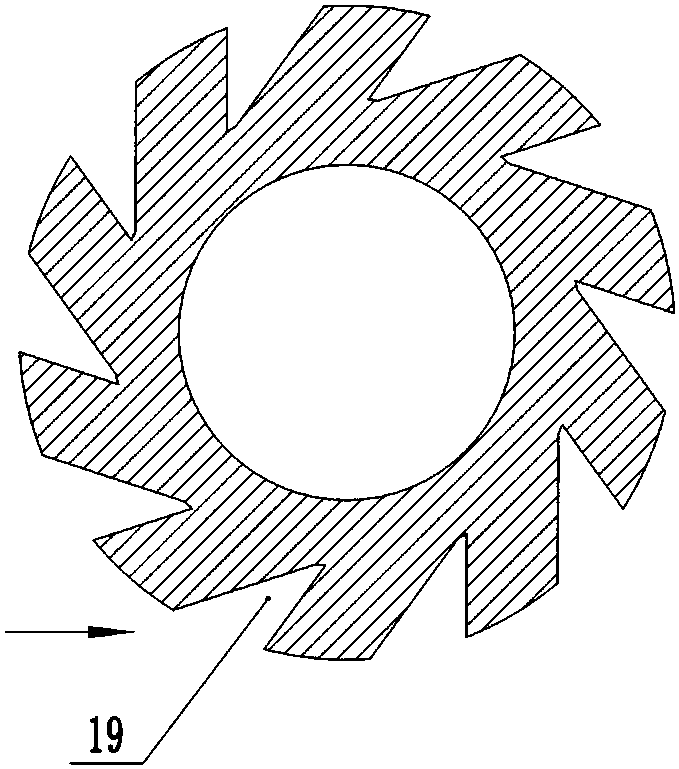

[0022] The reference signs in the drawings of the specification include: liquid storage chamber 1, dust removal chamber 2, liquid collection chamber 3, pipeline 4, circulation pump 5, cover body 6, first baffle plate 7, second baffle plate 8, air outlet pipe 9. Dust detector 10, air inlet pipe 11, dust collection chamber 12, one-way valve 13, valve 14, catheter 15, through hole 16, air bag 17, heating wire 18, groove 19.

[0023] The embodiment is basically as attached figure 1 Shown:

[0024] The invention discloses a dedusting device without disassembly and cleaning, which includes a box body, a cover body 6 is arranged on the top of the box body, and a first baffle plate 7 and a second baffle plate 8 are sequentially arranged on the box body from top to bottom. The plate 7 and the second baffle 8 respectively distribute the liquid storage chamber 1, the dust removal chamber 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com