A light-weight and expandable spatial truss-type capture manipulator

A truss-type, lightweight technology, used in aerospace equipment, transportation and packaging, tools, etc., can solve problems such as difficult to control stiffness, small grasping force, and no consideration of folding and unfolding functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

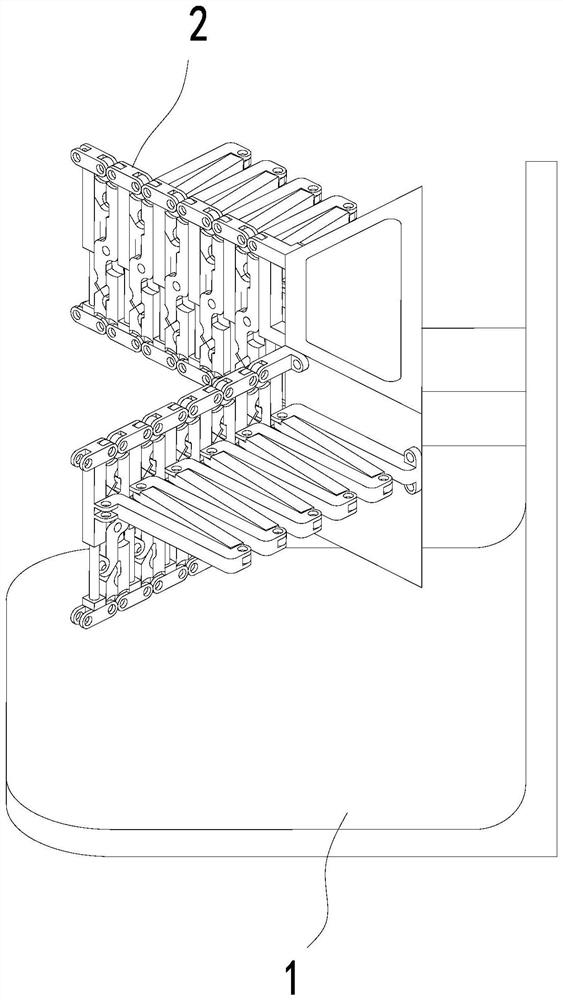

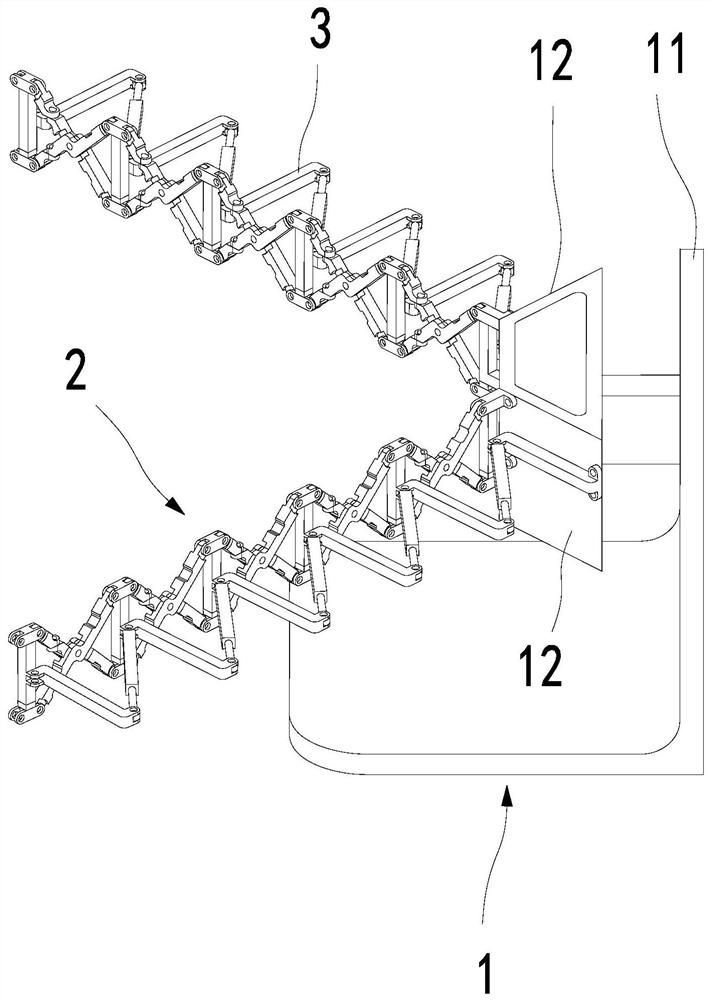

[0046] This embodiment provides a light-weight and expandable space truss-type capture manipulator, such as Figure 1-8 As shown, it includes a base 1 and two identical manipulator claws 2, wherein the base 1 includes an assembly base 11 and two sub-assembly bases 12 arranged on the assembly base 11, and the two manipulator claws 2 are respectively It is installed on two sub-packaging bases 12; specifically, two manipulator claws 2 are arranged facing each other.

[0047] Such as figure 1 As shown, it shows the state that the two manipulator claws 2 are closed, and as figure 2 As shown, it shows the extended state of the two manipulator claws 2; in order to suit the grasping of different non-cooperative objects, the mounting surfaces of the two sub-assembly bases 12 may also have an included angle, for example, the included angle is 90 degrees.

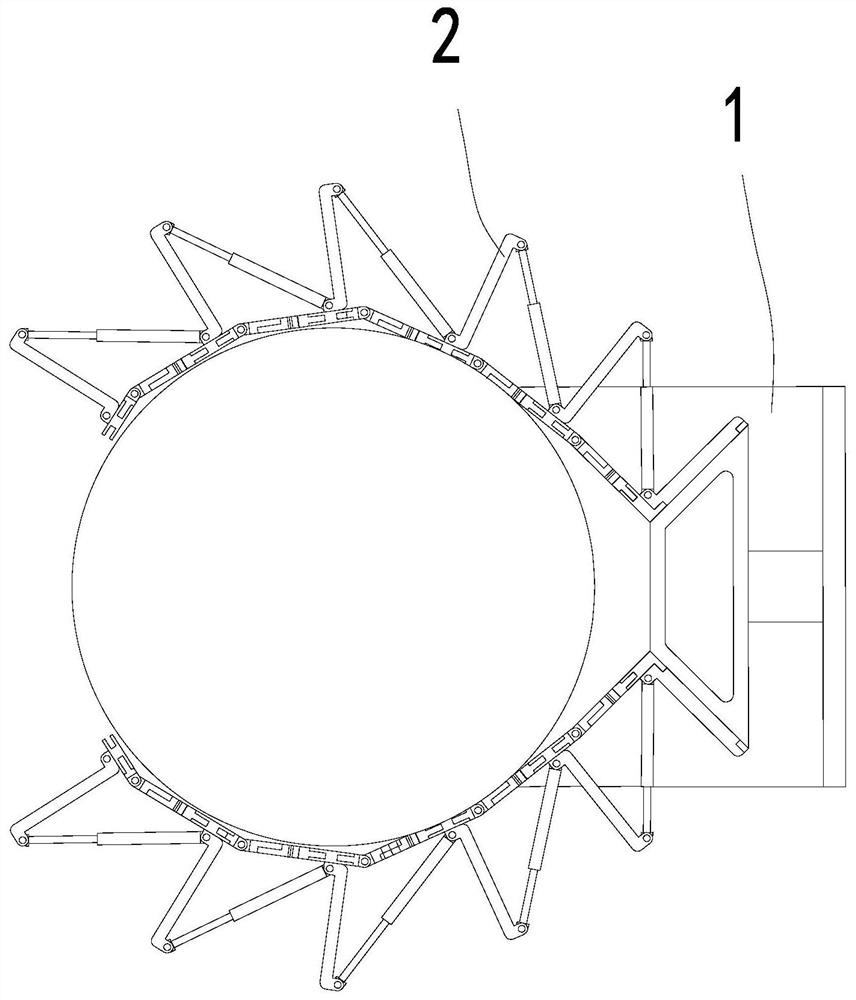

[0048] see image 3 , which shows the state that the two manipulator claws 2 of the present embodiment cooperate to capture the ...

Embodiment 2

[0063] This embodiment provides a light-weight and expandable space truss-type capture manipulator, such as Figure 9-10 As shown, the difference between this embodiment and embodiment 1 is that the location of the metamorphosis of the folding unit 3 is different, see Figure 9 , when the axes of the two rotating pairs R2 between the two reversing scissor bars 332 and the two telescopic scissor bars 331 are collinear, the angle between the two telescopic scissor bars 331 is 120 degrees, and the two reversing scissor bars The included angle between the fork bar 332 and the top support bar 311 is 30 degrees, and at this moment, the two turning scissor bars 332 have the turning function.

[0064] Further, the T-shaped truss in this embodiment adopts a triangular plate-shaped truss.

[0065] In this embodiment, the drive branch chain 34 can also include a slide rail 343 and a slide member 344 arranged on the slide rail 343, the cylinder body of the air cylinder (not shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com