Numerical control machine control system

A control system and CNC machine tool technology, applied in automatic control devices, manufacturing tools, metal processing mechanical parts, etc., can solve the problems of inability to change the working mode of the machine tool, single function, etc., and achieve rich functions, high detection accuracy, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

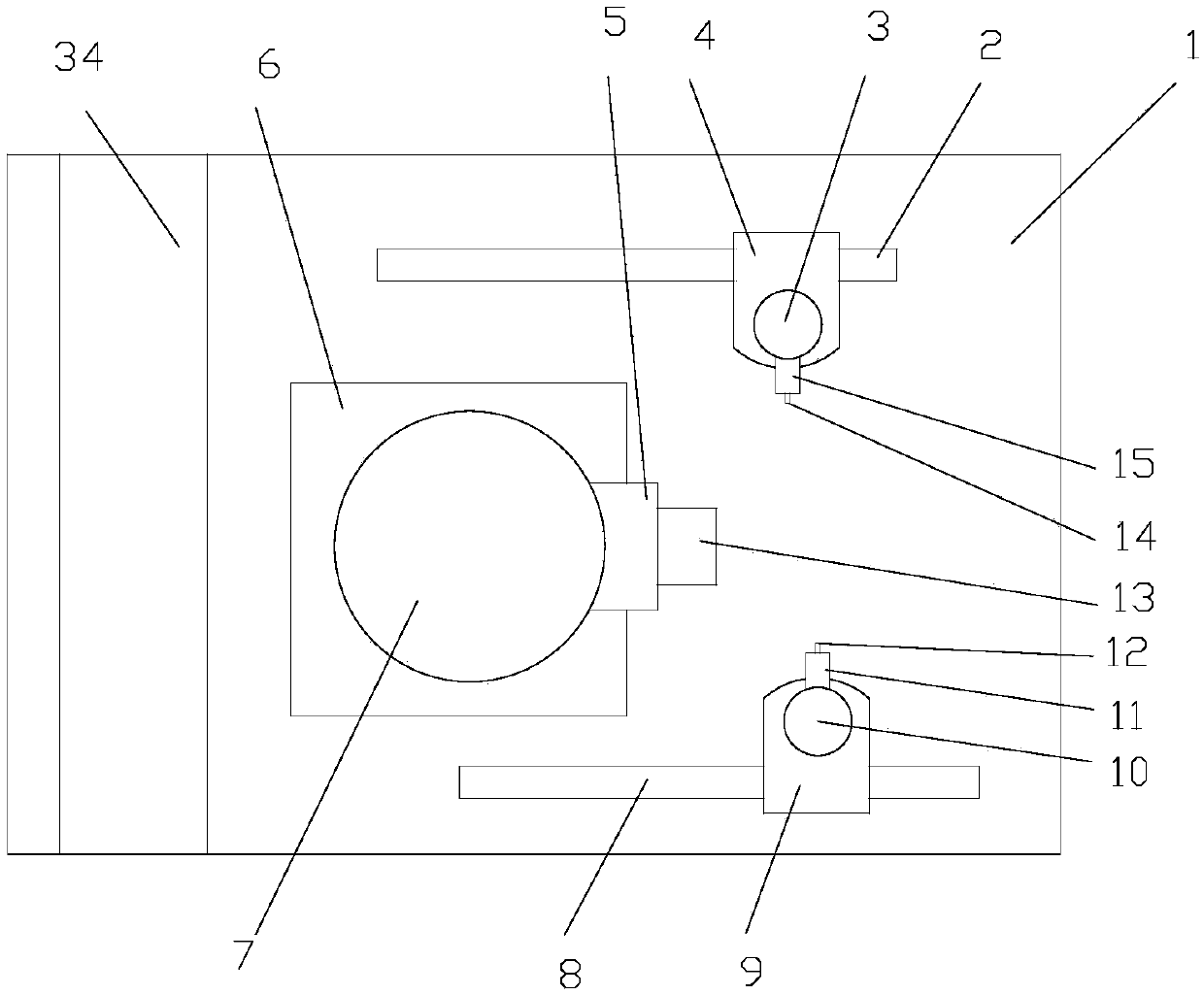

[0082] Embodiment 1: as figure 1 , a CNC machine tool control system, comprising a base 1 and a workpiece clamping device and a first tool clamping device arranged on the base;

[0083] The workpiece clamping device is provided with a workpiece chuck 5 for clamping the workpiece;

[0084] The first tool holding device includes a first guide rail 2, a first slide block 4, a first rotating platform 3, a first tool chuck 15 and a first processing head 14; the first tool head is preferably used for boring or grinding;

[0085] The first slider is arranged on the first guide rail 2, and can slide along the first guide rail 2 under the action of the sliding drive motor; the first guide rail 2 is arranged in the X-axis direction;

[0086] The first rotating platform is arranged on the first slide block, driven by the driving mechanism, it can rotate around the Z axis on the first rotating platform 3, and the first tool chuck 15 is fixed on the first rotating platform; A tool chuck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com