Digital design method of removable partial denture rest

A design method and design scheme technology, applied in medical science, dentistry, dental prosthesis, etc., can solve the problems of reducing production efficiency, wasting work time, and wasting more time, so as to reduce the impact of calculation speed and improve production efficiency , the effect of reducing the difficulty of training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

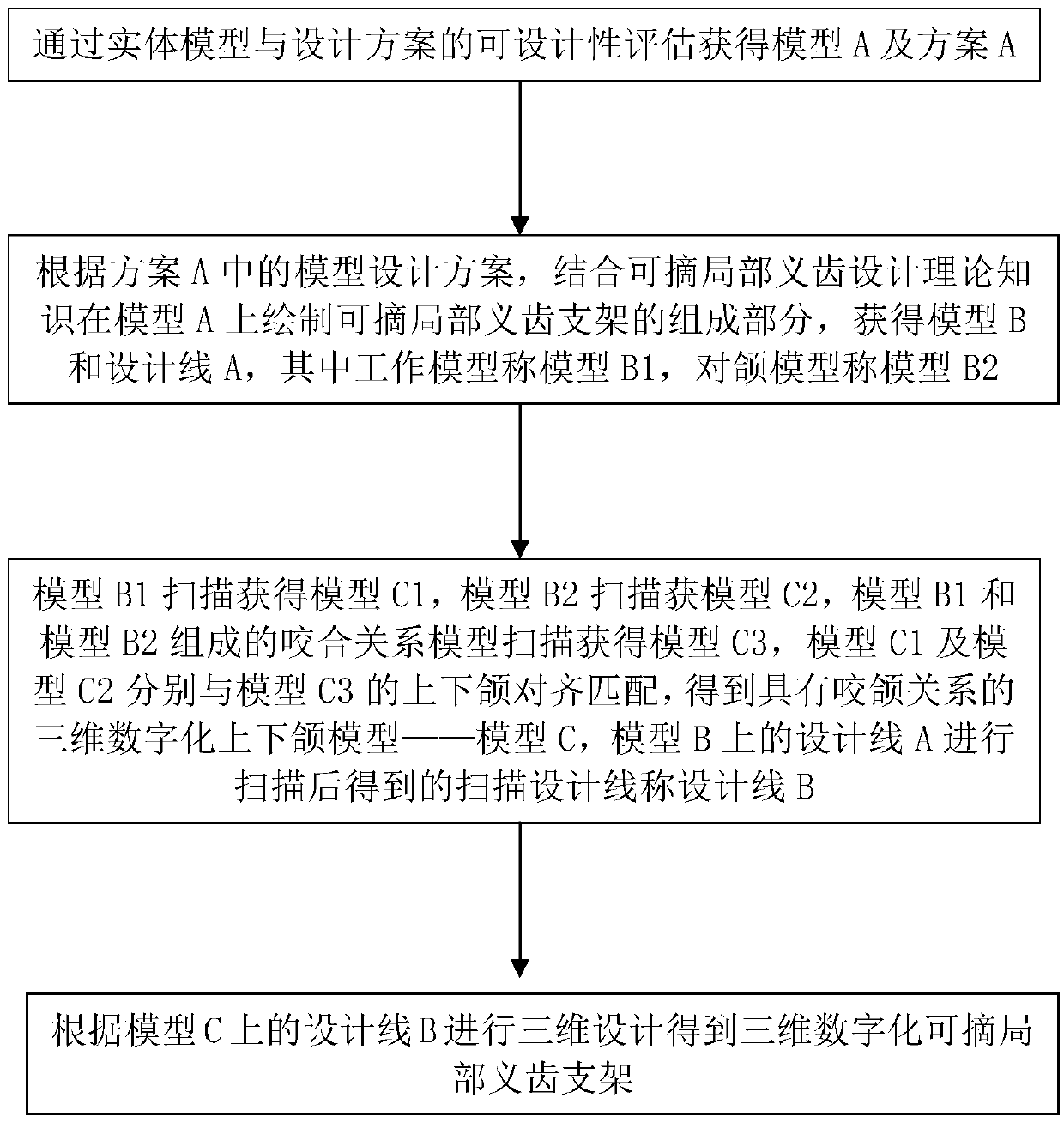

[0061] The present invention firstly draws the design lines of the components of the removable partial denture bracket on a solid model (such as a plaster model), then performs three-dimensional scanning, and performs three-dimensional design according to the scanned design lines. Drawing the design line of the solid model bracket provides shape guidance for the three-dimensional design of the digital bracket, which can greatly reduce the modification of the digital design, reduce the impact on the calculation speed of the design software, and improve production efficiency. As a preferred embodiment, it specifically includes the following steps:

[0062] Remove defects such as gypsum tumors on model A, and if necessary, perform the operations required by the model treatment plan in plan A, and restore the occlusal relationship of the model after completion.

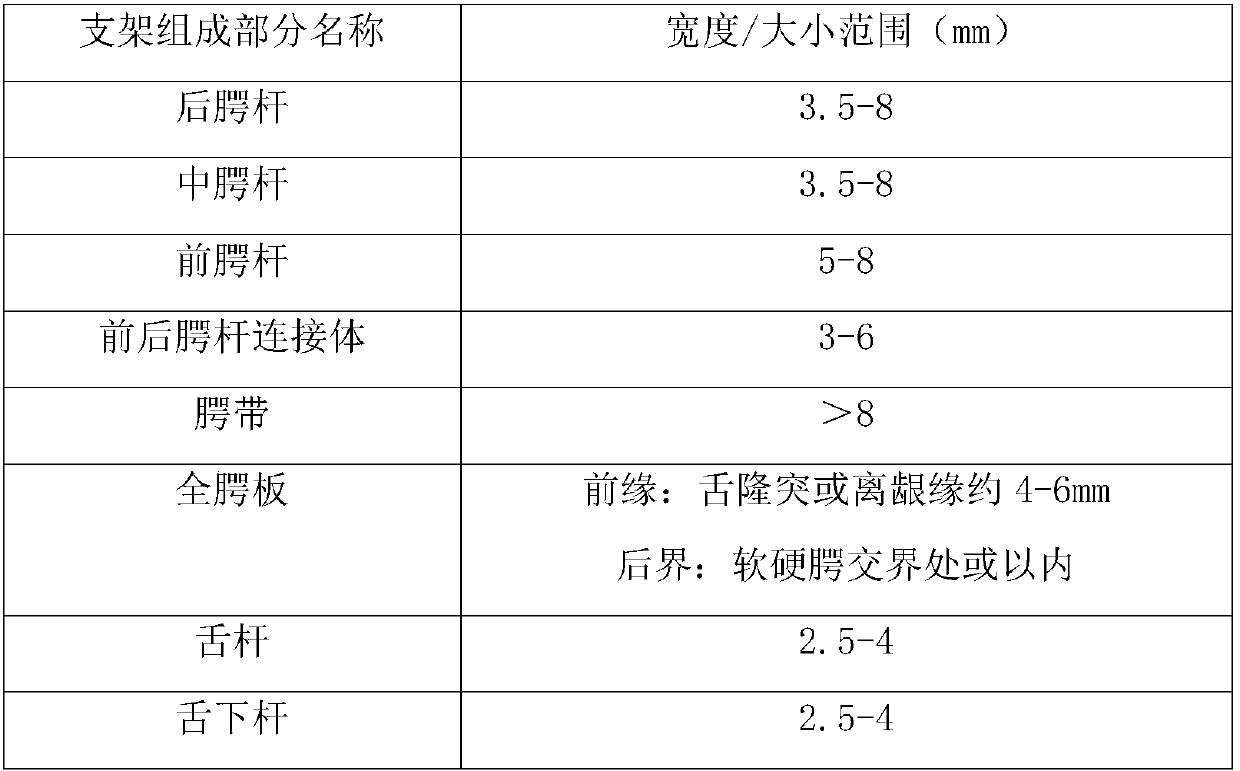

[0063] According to the model design scheme in plan A, combined with the theoretical knowledge of removable partial den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com