Summer and autumn tea processing method, tea, tea bag and drinks

A processing method and tea technology, which is applied in the processing of summer and autumn tea, bag tea and beverages, and the field of tea, can solve the problems of aroma loss, low dissolution rate of active ingredients at one time, and weak taste, so as to improve quality, realize degradation and detoxification The effect of removing and reducing bitterness and astringency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

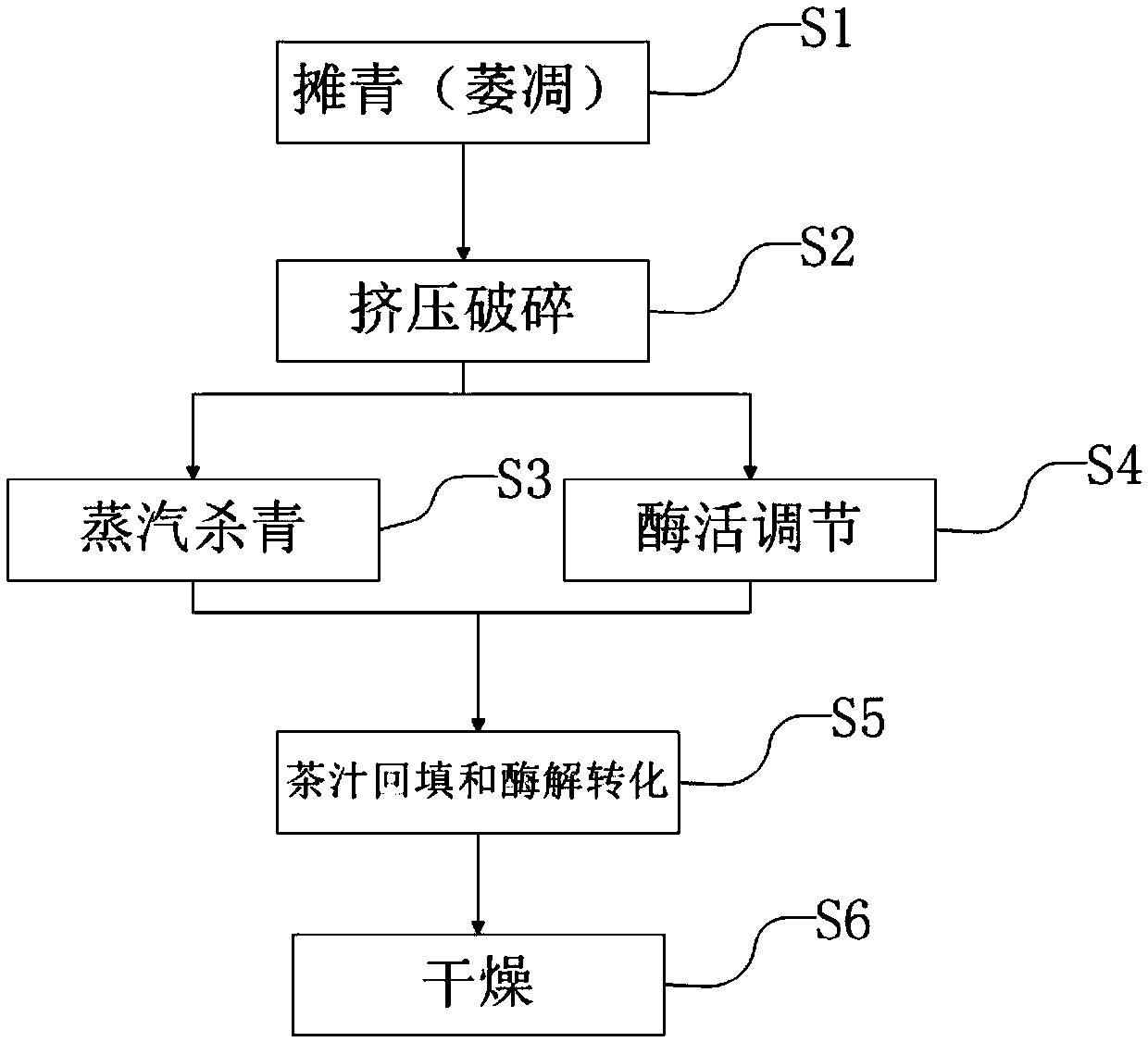

[0118] A kind of summer tea processing method, comprises the following steps:

[0119] (1) Spread green: spread 200kg of fresh leaves of machine-picked summer tea evenly on the withering mat, with a thickness of 5-8cm, spread for 20-30min, shake and turn once every 10min; then turn to room temperature wither, spread on Indoor withering mat, thickness 3-5cm, spread time 2-4h, lightly shake once every 30min, until the water content of fresh tea leaves is 50-70%;

[0120] (2) Extrusion and crushing: crushing and crushing the green leaves at a speed of 35 rpm / min for 10 minutes to obtain broken tea pieces and tea juice respectively;

[0121] (3) Steaming: Steam the crushed tea pieces for 55s under steam pressure of 0.04MPa, followed by cold air treatment for 40s;

[0122] (4) Enzyme activity regulation: add citric acid and ascorbic acid to the fresh tea juice, the total mass of citric acid and ascorbic acid in the tea juice accounts for 0.05% of the quality of the tea juice, and ...

Embodiment 2

[0131] The difference between this embodiment and Example 1 is that step (4) is replaced by: adding citric acid and ascorbic acid in the fresh tea juice, the total mass of citric acid and ascorbic acid in the tea juice accounts for 0.2% of the tea juice quality, and the tea juice The mass ratio of citric acid and ascorbic acid is 1:4.

[0132] The tea leaves obtained in Example 2 were brewed under different brewing conditions, and the test method was the same as in Example 1, and the results are shown in Table 2.

[0133] Table 2

[0134]

Embodiment 3

[0136] The difference between this embodiment and Example 1 is that step (4) is replaced by: adding citric acid and ascorbic acid in the fresh tea juice, the total mass of citric acid and ascorbic acid in the tea juice accounts for 0.1% of the tea juice quality, and the tea juice The mass ratio of citric acid and ascorbic acid in medium is 1:2.5.

[0137] The tea leaves obtained in Example 3 were brewed under different brewing conditions, and the test method was the same as in Example 1, and the results are shown in Table 3.

[0138] table 3

[0139]

[0140]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com