Preparation method of sodium ion conductor coated lithium-rich manganese-base stratified anode material

A sodium ion conductor and positive electrode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low energy density and relative capacity, affecting high-rate performance of materials, and low first-cycle coulombic efficiency. High production efficiency, easy control of reaction conditions, good repeatability of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

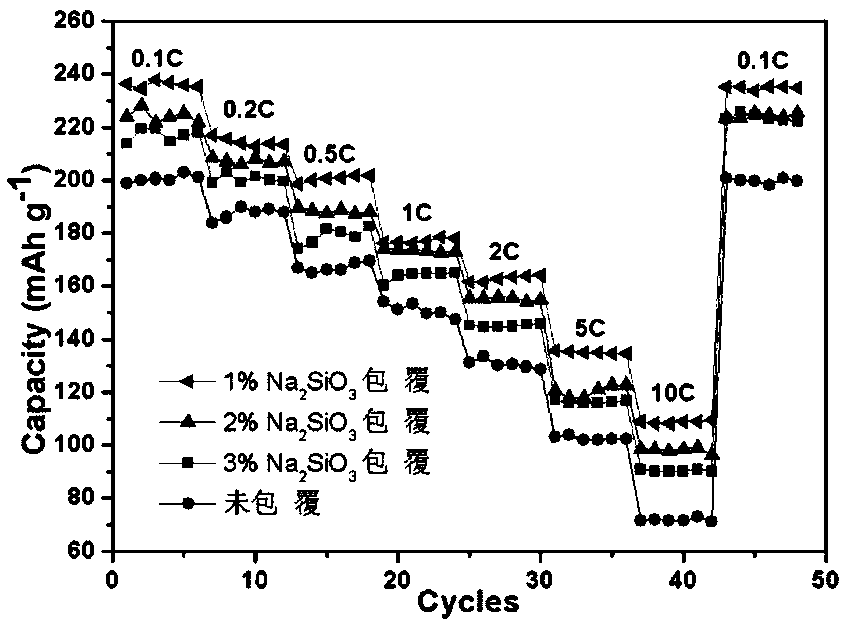

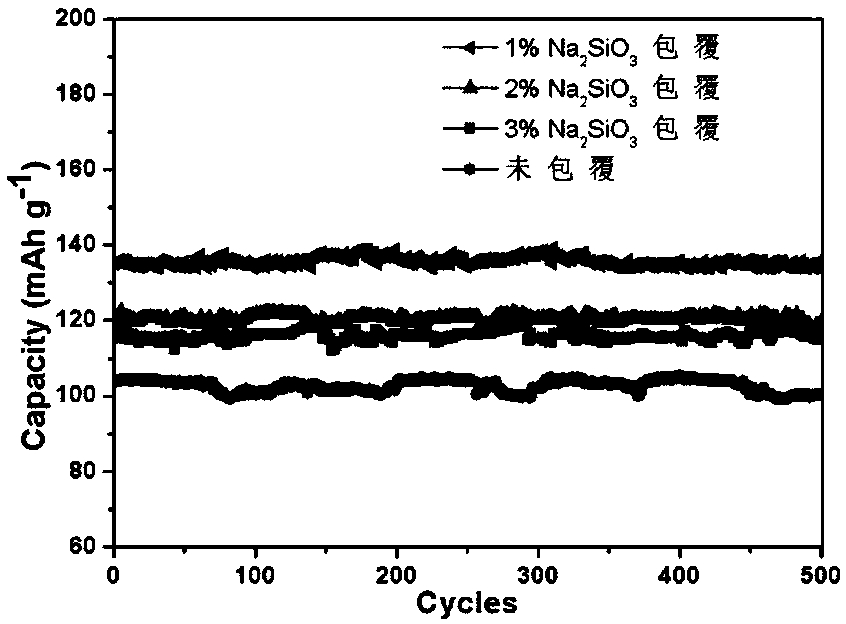

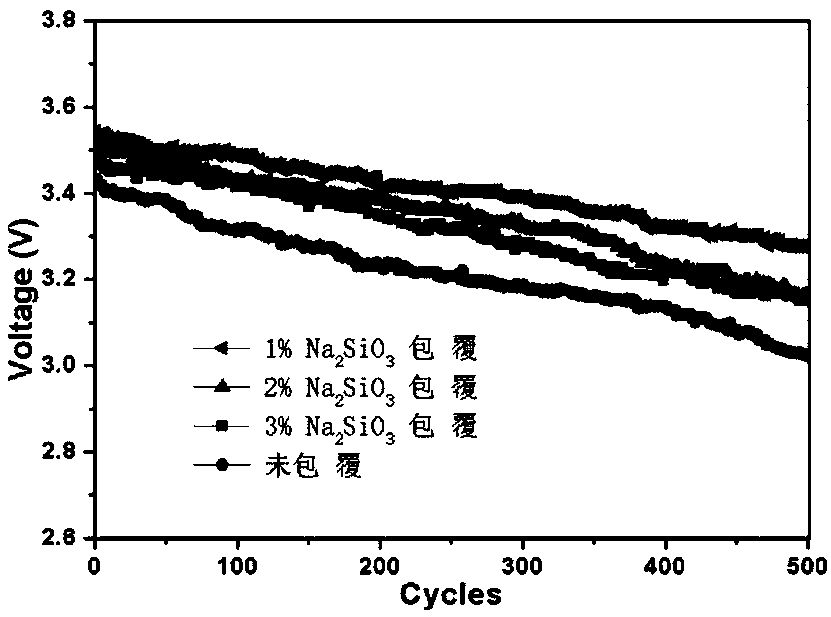

Examples

preparation example Construction

[0022] The preparation method of the sodium ion conductor coated lithium-rich manganese-based layered positive electrode material proposed by the method is coated by a direct stirring method, and the method includes the following steps:

[0023] (1) Preparation of carbonate precursor:

[0024]The metal salt of cobalt, the metal salt of nickel and the metal salt of manganese are dissolved in 100mL water according to the molar ratio, the metal salt of nickel: the metal salt of cobalt: the metal salt of manganese=0.1~0.3:0~0.3:0.4~0.9, The total molar concentration of metal ions is 1-3mol / L to obtain a mixed solution of metal ions; configure NaOH and NaOH with a molar concentration of 1-3mol / L 2 CO 3 , NaHCO 3 , (NH 4 ) 2 CO 3 or NH 4 HCO 3 100mL of any one of the precipitant solutions in the solution, add the precipitant solution to the above metal ion mixed solution under magnetic stirring to produce a precipitate, stir for 6 to 12 hours, centrifuge, and use deionized wa...

Embodiment 1

[0034] (1) Cobalt metal salt CoSO 4 Metal salt NiSO with nickel 4 Metal salt with manganese MnSO 4 Dissolve in 100mL water according to the molar ratio of 0.13:0.13:0.54, so that the total molar concentration of metal ions is 2mol / L to obtain a mixed solution of metal ions; the configuration molar concentration is 2mol / L Na 2 CO 3 Solution 50mL, under magnetic stirring, add the above precipitant solution into the above metal ion mixed solution to produce a precipitate. After stirring for 8 hours, centrifuge, wash the precipitate twice with deionized water and absolute ethanol respectively, and place the precipitate Dry in 80 ℃ oven for 12 hours, obtain carbonate precursor, the molecular formula of carbonate precursor is: (Ni 0.13 co 0.13 mn 0.54 ) 1.25 CO 3 2H 2 O.

[0035] (2) Combine the carbonate precursor obtained in the above step (1) with LiOH·H 2 O or Li 2 CO 3 Fully ground and mixed according to the molar ratio of 1:1.05, placed in a muffle furnace, calcine...

Embodiment 2

[0040] (1) Cobalt metal salt CoSO 4 Metal salt NiSO with nickel 4 Metal salt with manganese MnSO 4 Dissolve in 100mL water according to the molar ratio of 0.3:0.1:0.4, so that the total molar concentration of metal ions is 2mol / L to obtain a mixed solution of metal ions; the configuration molar concentration is 2mol / L Na 2 CO 3 Solution 50mL, under magnetic stirring, add the above precipitant solution into the above metal ion mixed solution to produce a precipitate. After stirring for 8 hours, centrifuge, wash the precipitate twice with deionized water and absolute ethanol respectively, and place the precipitate Dry in 80 ℃ oven for 12 hours, obtain carbonate precursor, the molecular formula of carbonate precursor is: (Ni 0.1 co 0.3 mn 0.4 ) 1.25 CO 3 2H 2 O.

[0041] (2) Combine the carbonate precursor obtained in the above step (1) with LiOH·H 2 O or Li 2 CO 3 Fully ground and mixed according to the molar ratio of 1:1.05, placed in a muffle furnace, calcined at 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com