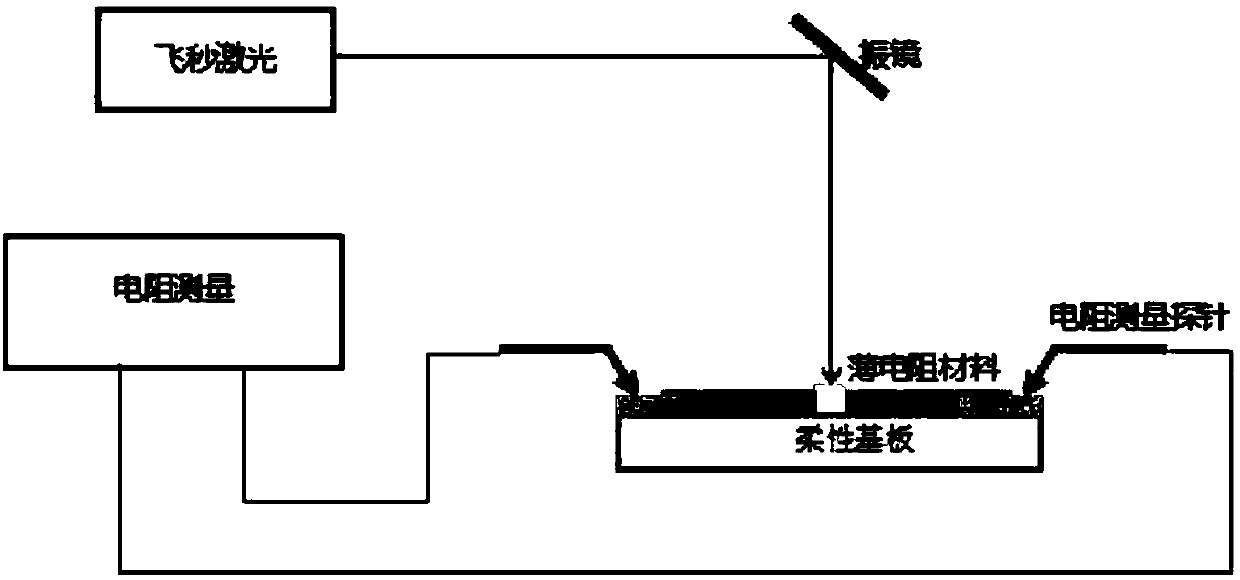

Method for precise resistor trimming on flexible substrate by using ultrafast laser

A flexible substrate, ultrafast laser technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as thermal damage, weak bonding between the resistance layer and the substrate, and poor thermal conductivity, achieving broad application prospects and improving Accuracy, Avoiding Thermal Damage Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0026] In a specific embodiment, a method for using ultrafast lasers to precisely adjust groups on a flexible substrate is disclosed, which includes the following processes in sequence:

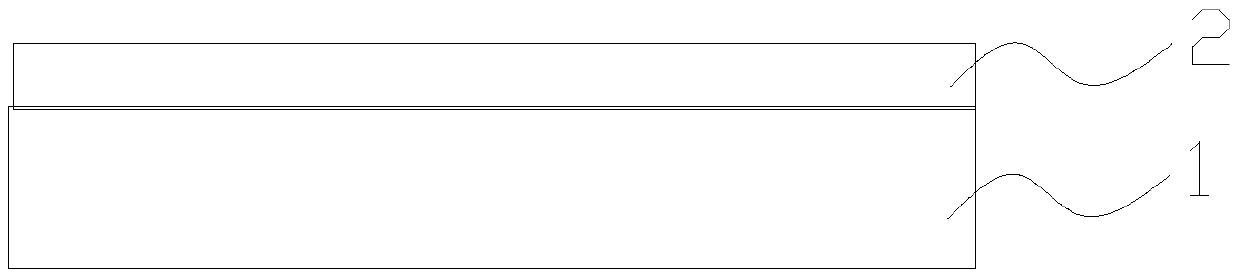

[0027] to combine figure 2 Firstly, place the flexible substrate 2 on the support jig 1. A suitable jig must be used so that the flexible substrate 2 can be unfolded flat and will not move easily, or a vacuum honeycomb flat plate is used to support the flexible substrate, such as vacuum adsorption.

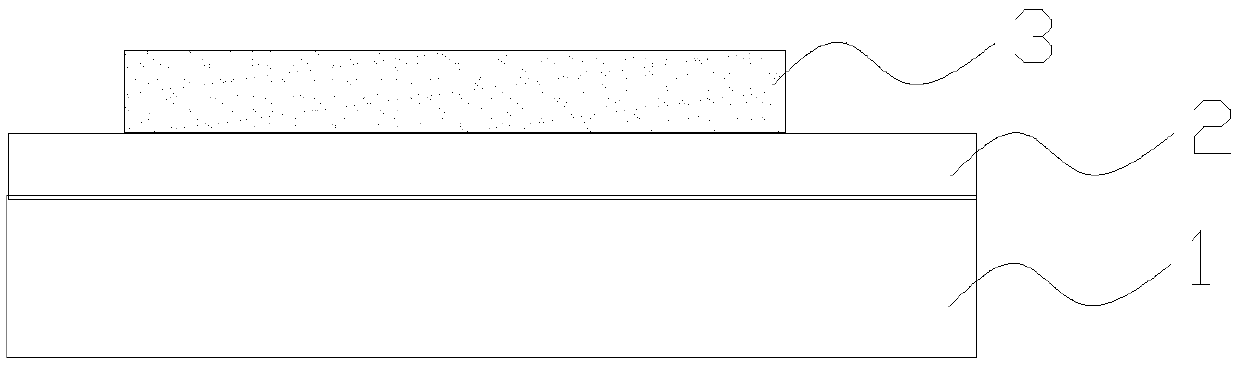

[0028] recombine image 3 , coating the precursor material of the resistance material on the flexible substrate 2 to form a wet film 3 . And specifically, printing or printing may be used to coat the precursor material on the flexible substrate 2 . And th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com