Electric spindle service life evaluation method without sudden failure information

A sudden failure and life evaluation technology, applied in the direction of electrical digital data processing, instruments, data processing applications, etc., can solve problems such as no sudden failure without consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

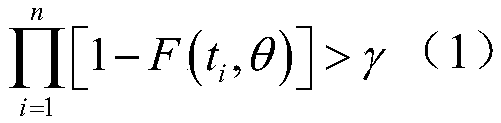

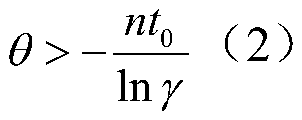

Method used

Image

Examples

Embodiment

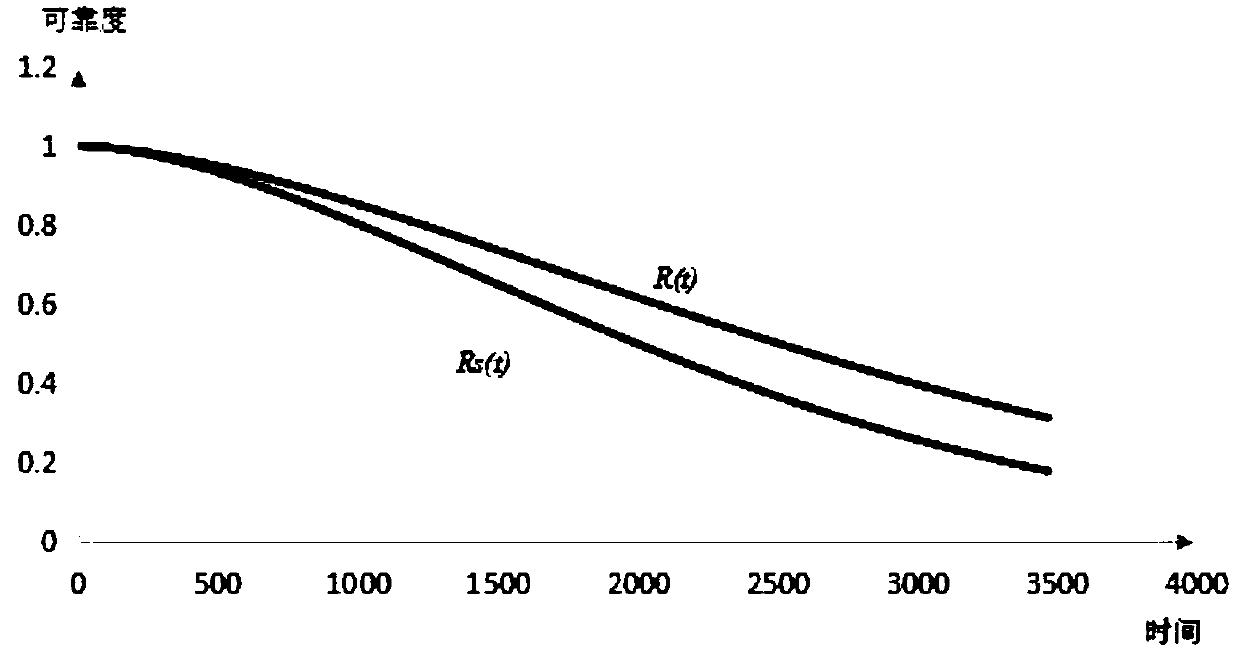

[0093] Electric spindle life assessment

[0094] Using the test information in Qiu Ronghua's "Small Sample Electric Spindle Reliability Test Based on Performance Degradation", the 170MD18Y16 electric spindle was used as the sample to carry out the stress load F Y =81.1N, 1700-hour timed truncation reliability test with the spindle speed of 9000r / min, the radial runout index of the shaft end is used to reflect the rotation accuracy of the spindle, and the radial runout of the shaft end of the FT5070F laser displacement sensor is selected to realize the collection of spindle performance degradation information , and part of the collected information is shown in Table 1.

[0095] Table 1 Data sheet of electric spindle performance degradation test (radial runout of shaft end) μm

[0096]

[0097]

[0098] When the radial runout of the shaft end reaches 1.6 times the initial value, the sample electric spindle fails.

[0099] Combined with the degradation data, Qiu Ronghua o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com