Electromagnetic heating metal phase diagram experimental method and experimental test tube

An experimental method and metal phase technology, applied in the investigation phase/state change and other directions, can solve the problems of rapid sample cooling rate, scrapping, large phase diagram drawing errors, etc., to shorten the experimental time, increase the experimental efficiency, and accurately control the temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

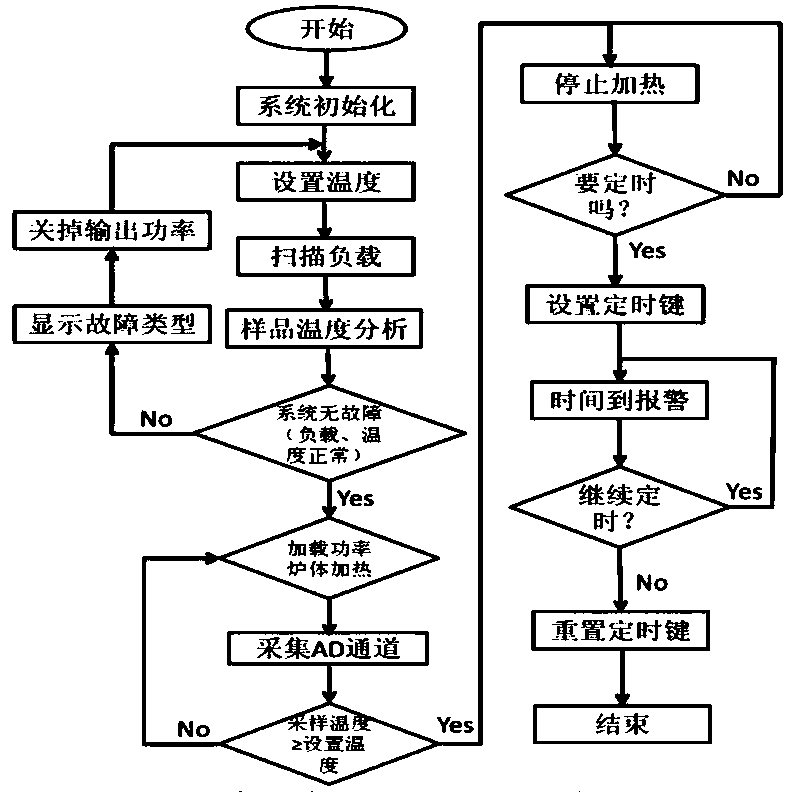

[0044] Such as figure 1 It is shown that the system initializes at the beginning of this method and sets the sample heating temperature. Since there is no residual heat in electromagnetic heating technology, the temperature is generally set at a position 40-50°C higher than the melting point of the sample in this experiment. The single-chip microcomputer scans whether there is a load in the heating furnace and the effectiveness of the load according to the magnitude of the input and output current and the direct relationship between the two, so as to avoid damage to electronic components due to excessive current.

[0045] The sample temperature detected by the thermocouple is transmitted to the single-chip control system by the AD acquisition card. After the system detects that all input signals are normal, the self-check passes. If a fault occurs, the system stops outputting current and displays the fault type on the instrument panel display to help users check the instrument’s p...

Embodiment 2

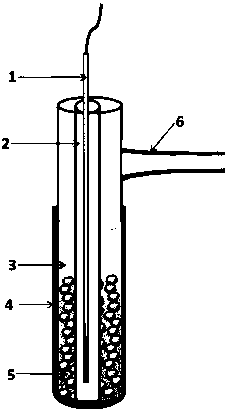

[0048] Such as figure 2 An electromagnetically heated metal phase diagram experimental test tube includes a test tube, an inner test tube and a cast iron sleeve. The inner test tube is set in the test tube, and the test tube is provided with liquid paraffin. A metal sample is impregnated in the paraffin, the test tube is provided with a test tube inlet, and the inner tube of the test tube is provided with a temperature sensor.

[0049] Electromagnetic heating requires that the heated body must be a magnetic material. On the outside of the original metal phase diagram measurement glass test tube, the cast iron sleeve is nested. Because cast iron has better magnetic permeability, higher electrical resistance and high thermal conductivity, it can meet the requirements of electromagnetic heating receivers. When the improved test tube is put into the heating furnace, under the action of electromagnetic heating, the cast iron sleeve begins to heat, and then heats the sample in the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com