Wet-heat exchanging device of solution humidity-control air-conditioning unit for capsule production

An air-conditioning unit and moisture-heat exchange technology, which is applied in household heating, household heating, air-conditioning systems, etc., can solve the problems of low solution humidity control and high energy consumption, and achieve the effect of reducing energy consumption and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

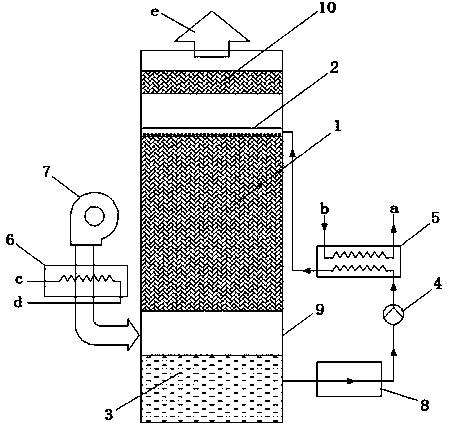

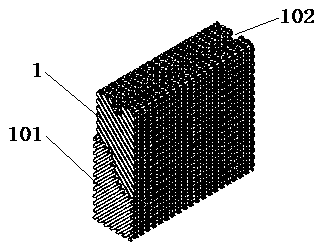

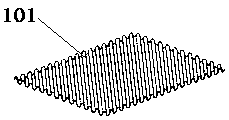

[0016] see Figure 1-Figure 4 , the first embodiment of the moisture-heat exchange device of the solution humidity-adjusting air-conditioning unit used for capsule production in the present invention, including a packing group 1 for moisture-heat exchange, a salt solution spray pipeline 2, and a box for storing salt Solution tank for solution 3, salt solution circulation pump 4, solution external cold and heat source heat exchanger 5, external cold and heat source air heat exchanger 6, air blower 7, solution regeneration device 8, device shell--corrosion-resistant box 9. Mist arrestor 10.

[0017] The middle part and the bottom of corrosion-resistant casing 9 are provided with packing and solution tank 3 respectively, and salt solution spray pipe 2 is arranged on each packing group 1; The lower part is connected; the lower part of the solution tank 3 is connected in series with the first channel of the solution regeneration device 8, the saline solution circulation pump 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com