Under-pressure isolation maintenance box of high-risk gas pipeline

A technology for inspection boxes and gas pipes, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of hidden energy, waste, and dangerous gas leakage in maintenance operations, so as to prevent accidents and install The effect of fast speed and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

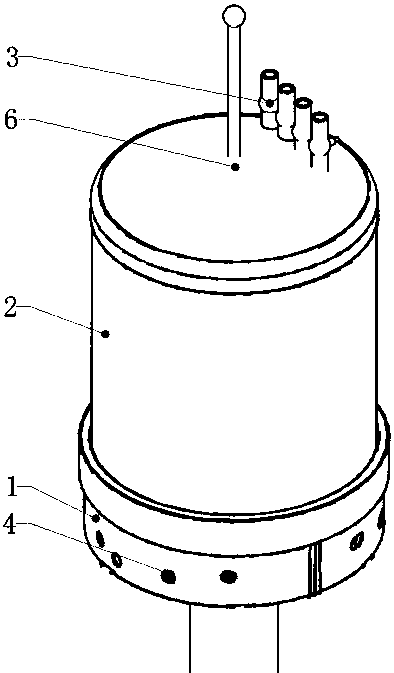

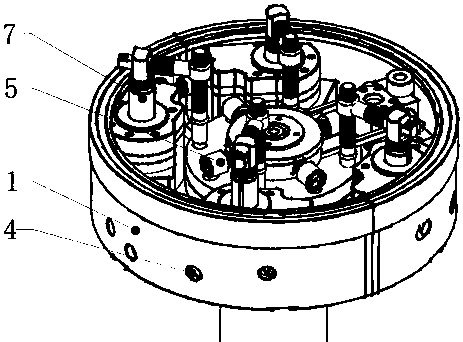

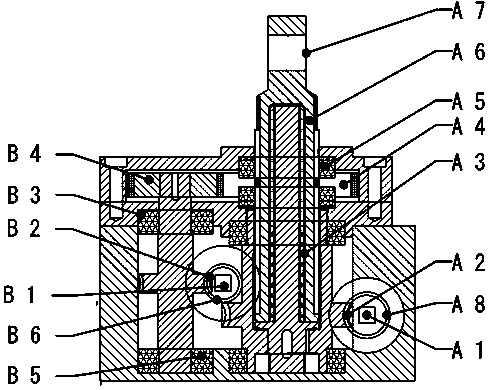

[0030] Such as Figure 1-Figure 6 The high-risk gas pipeline isolation inspection box shown includes a combined inspection box base. hole, on the base of the combination maintenance box, a lifting steering rod 7 and a blind plate gripper 5 are arranged, and a transmission mechanism is arranged in the base of the combination maintenance box. Unit connection, a visible isolation cover 2 is set outside the base of the combined maintenance box, and a pressure regulating unit 3 is arranged on the top of the visible isolation cover 2. The pressure regulating unit communicates with the visible isolation cover. The gas source is connected, and a valve lifter 6 is arranged on the top of the visible isolation cover 2 .

[0031] According to the present invention, the base of the inspection box combination inspection box is provided with a transmission mechanism, and the transmission mechanism consists of two sets, one is a lifting and steering transmission mechanism, the other is a bli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com