A kind of optical mold core nickel plating process

A technology of electroless nickel plating and electroless nickel plating solution, applied in the processing field, can solve the problems of the lens being unable to be cast, falling off, etc., to avoid bubbles and pinholes, and to improve the bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

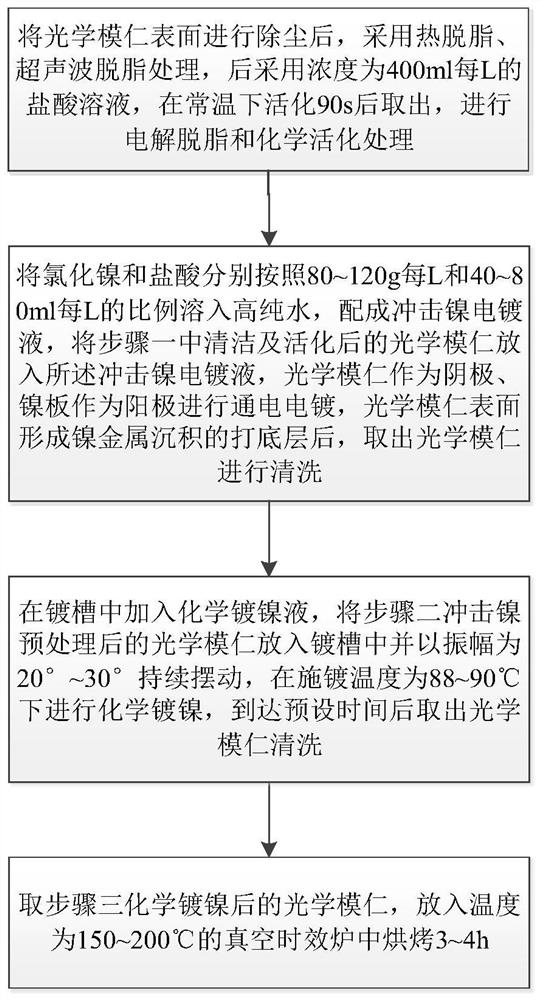

[0029] Embodiment 1: a kind of nickel-plating process for optical mold cores, comprising the following steps:

[0030] S1. Cleaning and activation: After dedusting the surface of the optical mold core, heat degreasing, ultrasonic degreasing, hydrochloric acid activation, electrolytic degreasing and chemical activation are used in sequence.

[0031] S1.1. Thermal degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50g / L, and degreasing at a temperature of 55°C for 8 minutes.

[0032] S1.2. Ultrasonic degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50g / L, and degreasing at an ultrasonic frequency of 40kHz and a temperature of 55°C for 90s.

[0033] The mass composition of the degreasing agent that thermal degreasing and ultrasonic degreasing adopt in the present embodiment comprises: sodium hydroxide 38%, sodium tripolyphosphate 1%, sodium metasilicate 10%, sodiu...

Embodiment 2

[0058] Embodiment 2: a kind of nickel-plating process for optical mold core, comprising the following steps:

[0059] S1. Cleaning and activation: After dedusting the surface of the optical mold core, heat degreasing, ultrasonic degreasing, hydrochloric acid activation, electrolytic degreasing and chemical activation are used in sequence.

[0060] S1.1. Thermal degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50 g / L, and degreasing at a temperature of 50° C. for 7 minutes.

[0061] S1.2. Ultrasonic degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50g / L, and degreasing at an ultrasonic frequency of 35kHz and a temperature of 50°C for 90s.

[0062] The mass composition of the degreasing agent that thermal degreasing and ultrasonic degreasing adopt in the present embodiment comprises: sodium hydroxide 38%, sodium tripolyphosphate 1%, sodium metasilicate 10%, sod...

Embodiment 3

[0072] Embodiment 3: a kind of nickel-plating process for optical mold cores, comprising the following steps:

[0073] S1. Cleaning and activation: After dedusting the surface of the optical mold core, heat degreasing, ultrasonic degreasing, hydrochloric acid activation, electrolytic degreasing and chemical activation are used in sequence.

[0074] S1.1. Thermal degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50g / L, and degreasing at a temperature of 45°C for 5 minutes.

[0075] S1.2. Ultrasonic degreasing treatment includes: putting the optical mold core into a degreasing agent with a concentration of 50g / L, and degreasing at an ultrasonic frequency of 30kHz and a temperature of 45°C for 90s.

[0076] The mass composition of the degreasing agent that thermal degreasing and ultrasonic degreasing adopt in the present embodiment comprises: sodium hydroxide 38%, sodium tripolyphosphate 1%, sodium metasilicate 10%, sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com