Enrichment method for rhenium in acid wastewater of copper smelting smoke purification system

A flue gas purification system and acid wastewater technology, which is applied in chemical instruments and methods, gaseous effluent wastewater treatment, water/sewage treatment, etc., can solve the problems of less research on rhenium recovery, difficulty in enrichment and recovery, easy dispersion of rhenium, etc. , to achieve the effect of improving the comprehensive utilization rate of resources, high enrichment rate and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

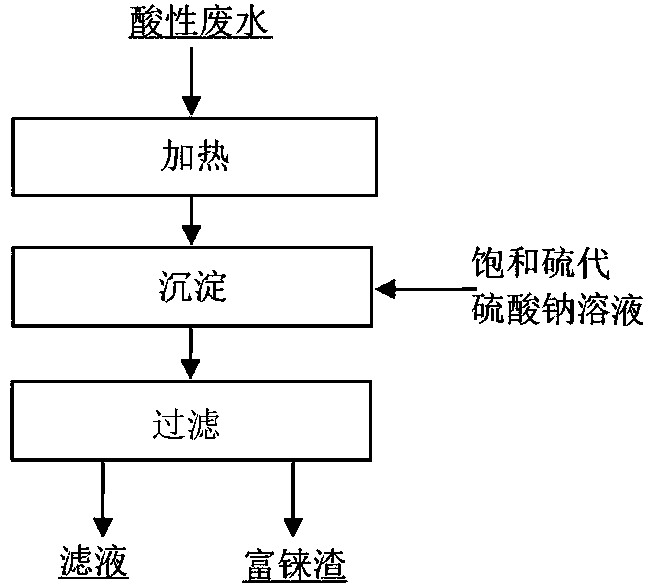

Method used

Image

Examples

Embodiment 1

[0009] Measure 5L of acidic wastewater from the copper smelting flue gas purification system, containing 10mg / L of rhenium in the acidic wastewater, place it on an electric heating plate and heat it to 40°C, then add saturated sodium thiosulfate solution, the saturated sodium thiosulfate added per liter of acidic wastewater The amount of the solution is based on the molar content of sodium thiosulfate, and the molar amount of sodium thiosulfate contained in the added saturated sodium thiosulfate solution is 1.2 times the molar amount of copper in the acidic waste liquid. After stirring for 3 hours in the heat preservation state, rhenium precipitated in the form of sulfide, left to age for a period of time and then filtered. The volume of the filtrate was 4.96L, and the rhenium content in the filtrate was 0.93mg / L. The rest of the rhenium entered the filter residue and dried. Filter residue, just obtain rich rhenium residue 3.88g, contain rhenium 0.083%. Based on slag, the enri...

Embodiment 2

[0011] Measure 5L of acidic wastewater from the flue gas purification system of copper smelting. The acidic wastewater contains 10mg / L of rhenium, heat it on a hot plate to 30°C, and then add saturated sodium thiosulfate solution. The saturated sodium thiosulfate added per liter of acidic wastewater The amount of the solution is based on the molar content of sodium thiosulfate, and the molar amount of sodium thiosulfate contained in the added saturated sodium thiosulfate solution is 1.3 times the molar amount of copper in the acidic waste liquid. After stirring for 4 hours under heat preservation, rhenium precipitated in the form of sulfide, left to age for a period of time and then filtered. The volume of the filtrate was 4.97L, and the rhenium content in the filtrate was 0.93mg / L. The remaining rhenium entered the filter residue and dried again. Filter residue, just obtain rich rhenium residue 3.90g, contain rhenium 0.085%. Based on slag, the enrichment rate of rhenium is 97...

Embodiment 3

[0013] Measure 5L of acidic wastewater from the flue gas purification system of copper smelting. The acidic wastewater contains 10mg / L of rhenium, heat it on a hot plate to 50°C, and then add saturated sodium thiosulfate solution. The saturated sodium thiosulfate added per liter of acidic wastewater The amount of the solution is based on the molar content of sodium thiosulfate, and the molar amount of sodium thiosulfate contained in the added saturated sodium thiosulfate solution is 1.1 times the molar amount of copper in the acidic waste liquid. After stirring for 2 hours in the heat preservation state, rhenium precipitated in the form of sulfide, left to age for a period of time and then filtered. The volume of the filtrate was 4.96L, and the rhenium content in the filtrate was 0.93mg / L. The remaining rhenium entered the filter residue and dried. Filter residue, just obtain rich rhenium residue 3.85g, contain rhenium 0.082%. Based on slag, the enrichment rate of rhenium is 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com